Programmable Logic Controllers (PLCs) excel in discrete manufacturing processes with their high-speed, real-time control and modular design, making them ideal for automation tasks requiring rapid response. Distributed Control Systems (DCS) specialize in continuous process industries by offering centralized control, integrated data management, and enhanced reliability for complex process monitoring. Choosing between PLC and DCS depends on the industrial application's scale, process complexity, and need for flexibility versus centralized oversight.

Table of Comparison

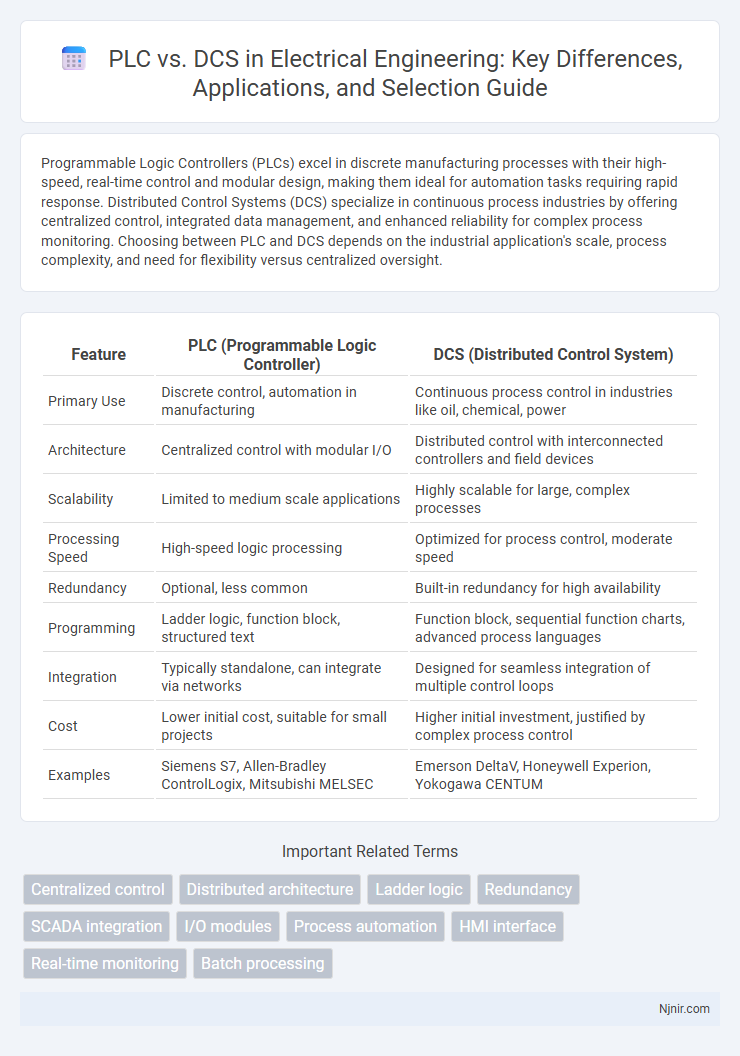

| Feature | PLC (Programmable Logic Controller) | DCS (Distributed Control System) |

|---|---|---|

| Primary Use | Discrete control, automation in manufacturing | Continuous process control in industries like oil, chemical, power |

| Architecture | Centralized control with modular I/O | Distributed control with interconnected controllers and field devices |

| Scalability | Limited to medium scale applications | Highly scalable for large, complex processes |

| Processing Speed | High-speed logic processing | Optimized for process control, moderate speed |

| Redundancy | Optional, less common | Built-in redundancy for high availability |

| Programming | Ladder logic, function block, structured text | Function block, sequential function charts, advanced process languages |

| Integration | Typically standalone, can integrate via networks | Designed for seamless integration of multiple control loops |

| Cost | Lower initial cost, suitable for small projects | Higher initial investment, justified by complex process control |

| Examples | Siemens S7, Allen-Bradley ControlLogix, Mitsubishi MELSEC | Emerson DeltaV, Honeywell Experion, Yokogawa CENTUM |

Introduction to PLC and DCS Systems

Programmable Logic Controllers (PLC) are digital computers designed for real-time industrial automation, offering high-speed processing, flexibility, and ease of programming for discrete control tasks. Distributed Control Systems (DCS) provide centralized control with a hierarchical architecture, ideal for complex, continuous process automation with integrated feedback loops and process monitoring. Both systems enhance operational efficiency but differ in scalability, control strategies, and application environments within manufacturing and process industries.

Core Architecture Comparison

PLC (Programmable Logic Controller) architecture centers on modular, discrete I/O with a processor executing ladder logic or structured text, optimized for fast, real-time industrial automation tasks. DCS (Distributed Control System) architecture features a hierarchical, distributed network of controllers and operator stations designed for complex process control with continuous data flow and integrated sensor feedback. While PLCs excel in discrete control applications with rapid response times, DCS provides robust scalability and redundancy suited for large-scale, continuous process industries.

Scalability and Flexibility

PLC systems offer high scalability and flexibility, making them ideal for small to medium-sized industrial automation projects where modular expansion and customization are crucial. DCS solutions excel in handling large-scale, complex processes with integrated control and monitoring, providing seamless scalability through distributed architecture suited for continuous production environments. The choice between PLC and DCS depends on the required system complexity, with PLCs favored for flexible, discrete control and DCS preferred for scalable, centralized process management.

Application Suitability

PLC systems excel in discrete manufacturing processes requiring fast response times and high flexibility, such as automotive assembly lines and packaging operations. DCS solutions are ideal for continuous or batch process industries like chemical plants and power generation, offering superior control and monitoring over complex, large-scale processes. Selecting between PLC and DCS depends on factors like process complexity, scale, and real-time control needs, with PLCs favoring modular automation and DCS providing integrated process management.

Communication Protocols

PLC systems predominantly utilize Ethernet/IP, Modbus TCP/IP, and Profibus protocols, ensuring high-speed communication suitable for discrete control applications. DCS platforms favor protocols like Foundation Fieldbus, HART, and DeviceNet, which support process control environments with extensive device integration and diagnostics. Both systems leverage OPC UA for standardized data exchange, enhancing interoperability across diverse industrial networks.

System Integration Capabilities

PLCs offer modular and flexible system integration capabilities ideal for discrete control processes, supporting multiple communication protocols like Ethernet/IP and Modbus for seamless interoperability. DCS systems provide centralized control with robust integration across continuous and batch processes, enabling real-time data exchange, advanced process automation, and comprehensive asset management through native support of OPC UA and fieldbus standards. Combining PLCs and DCS can optimize complex industrial environments by leveraging PLCs' device-level control strengths and DCS's high-level process coordination and system-wide integration.

Cost Analysis and Ownership

PLC systems typically offer lower initial costs and simpler installation, making them cost-effective for smaller or modular automation projects. DCS systems involve higher upfront investment due to integrated hardware and software designed for complex, large-scale process control, but provide long-term savings through centralized maintenance and reduced downtime. Ownership costs for PLCs may increase with scaling and complexity, while DCS ownership emphasizes optimized lifecycle management and comprehensive support reducing total cost of ownership over time.

Maintenance and Support Considerations

PLC systems typically offer easier maintenance and faster troubleshooting due to their modular design and standardized programming languages like Ladder Logic, enabling technicians to quickly replace or upgrade components. DCS platforms, designed for complex process control, require specialized knowledge for maintenance and support, often involving vendor-specific tools and integrated diagnostics that facilitate predictive maintenance but may increase reliance on manufacturer assistance. Both systems benefit from remote monitoring capabilities, though DCS environments usually support more advanced diagnostics and centralized control strategies that optimize long-term maintenance schedules.

Reliability and Redundancy

PLC systems offer high-speed processing and modular architecture but generally have limited built-in redundancy compared to DCS, which are designed with advanced fault-tolerant features and multiple redundancy layers for enhanced reliability in critical industrial processes. DCS typically incorporate redundant controllers, communication pathways, and power supplies, ensuring continuous operation during component failures, making them ideal for large-scale, complex environments requiring maximum uptime. PLCs can achieve redundancy through external configurations but often lack the seamless integration and comprehensive backup capabilities inherent in DCS architectures.

Future Trends in Industrial Automation

Future trends in industrial automation emphasize the integration of PLCs (Programmable Logic Controllers) and DCS (Distributed Control Systems) with advanced IIoT (Industrial Internet of Things) technologies, enabling real-time data analytics and predictive maintenance. The evolution towards edge computing enhances the processing capabilities of PLCs at the device level, while DCS platforms increasingly adopt cloud-based solutions for scalable control and monitoring across complex industrial processes. Cybersecurity and AI-driven optimization are becoming critical components, driving the convergence of PLC and DCS architectures to create more intelligent, flexible, and resilient automation systems.

Centralized control

DCS offers centralized control with integrated real-time monitoring and distributed control capabilities ideal for large, complex industrial processes, whereas PLCs typically provide localized control suited for smaller, discrete automation tasks.

Distributed architecture

A PLC system uses decentralized controllers optimized for discrete control and fast response, while a DCS employs a fully distributed architecture integrating control, monitoring, and data acquisition across multiple interconnected processors for continuous process management.

Ladder logic

PLC systems predominantly utilize ladder logic for programmable control, offering straightforward, visual programming ideal for discrete manufacturing, whereas DCS typically employs function block or sequential function charts better suited for continuous process control.

Redundancy

Redundancy in PLC systems typically involves hot-standby CPUs for quick failover, while DCS offers comprehensive redundancy across controllers, communication networks, and I/O modules to ensure continuous process control.

SCADA integration

PLCs offer flexible and cost-effective SCADA integration for discrete control, while DCS provides seamless, centralized SCADA integration optimized for complex process industries requiring high reliability and scalability.

I/O modules

PLC systems feature modular and flexible I/O modules for discrete control applications, while DCS I/O modules emphasize integration, redundancy, and scalability for continuous process automation.

Process automation

PLC systems excel in discrete control tasks with fast response times, while DCS platforms optimize continuous process automation through centralized control and advanced data integration.

HMI interface

PLC systems feature customizable HMIs optimized for discrete process control, while DCS HMIs provide integrated, real-time visualization and management suited for continuous, complex industrial processes.

Real-time monitoring

PLC systems provide faster real-time monitoring with high-speed processing for discrete control, while DCS excels in continuous process control by integrating real-time data from multiple sources for comprehensive plant-wide monitoring.

Batch processing

PLC systems offer faster response times and flexibility for discrete batch processing, while DCS provides superior scalability and integrated control for complex continuous batch operations in large-scale industrial environments.

PLC vs DCS Infographic

njnir.com

njnir.com