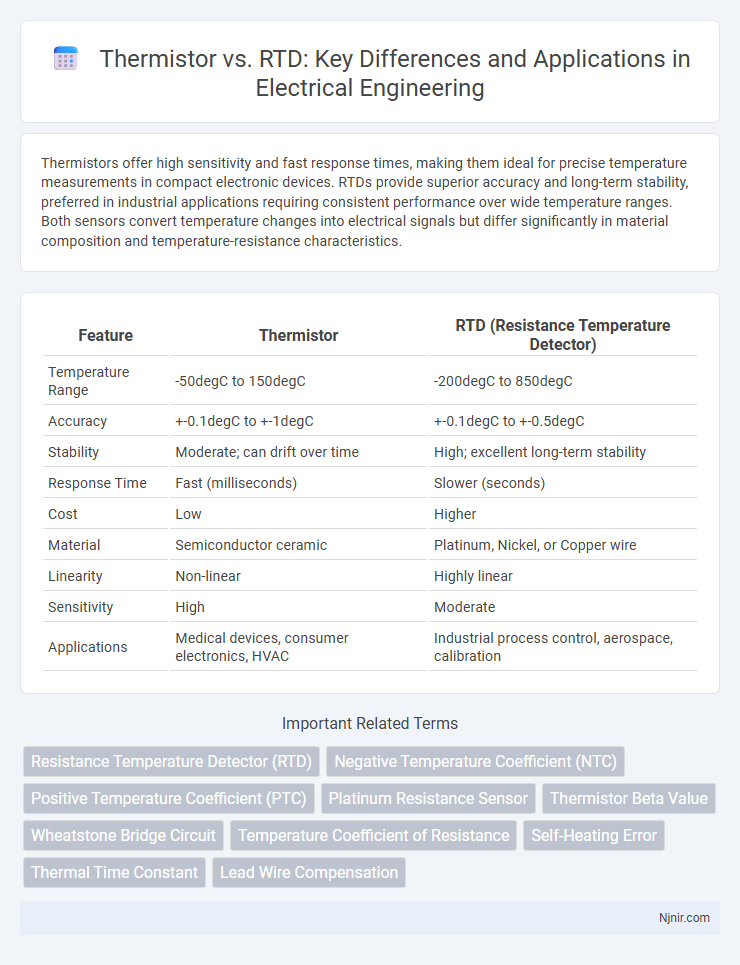

Thermistors offer high sensitivity and fast response times, making them ideal for precise temperature measurements in compact electronic devices. RTDs provide superior accuracy and long-term stability, preferred in industrial applications requiring consistent performance over wide temperature ranges. Both sensors convert temperature changes into electrical signals but differ significantly in material composition and temperature-resistance characteristics.

Table of Comparison

| Feature | Thermistor | RTD (Resistance Temperature Detector) |

|---|---|---|

| Temperature Range | -50degC to 150degC | -200degC to 850degC |

| Accuracy | +-0.1degC to +-1degC | +-0.1degC to +-0.5degC |

| Stability | Moderate; can drift over time | High; excellent long-term stability |

| Response Time | Fast (milliseconds) | Slower (seconds) |

| Cost | Low | Higher |

| Material | Semiconductor ceramic | Platinum, Nickel, or Copper wire |

| Linearity | Non-linear | Highly linear |

| Sensitivity | High | Moderate |

| Applications | Medical devices, consumer electronics, HVAC | Industrial process control, aerospace, calibration |

Introduction to Temperature Sensors in Electrical Engineering

Thermistors and RTDs are essential temperature sensors in electrical engineering, offering precise thermal measurements for control and monitoring systems. Thermistors typically provide high sensitivity and are made from ceramic materials whose resistance varies significantly with temperature. RTDs, usually composed of platinum, deliver superior accuracy and stability over a wide temperature range, making them ideal for industrial applications.

Overview of Thermistors: Types and Principles

Thermistors are temperature sensors made from semiconductor materials exhibiting a significant change in resistance with temperature. They primarily come in two types: Negative Temperature Coefficient (NTC) thermistors, which decrease resistance as temperature rises, and Positive Temperature Coefficient (PTC) thermistors, which increase resistance with temperature. Their rapid response time and high sensitivity make thermistors ideal for precise temperature measurements in various applications from medical devices to HVAC systems.

Understanding RTDs: Construction and Function

RTDs (Resistance Temperature Detectors) consist of a pure metal wire, typically platinum, wound around a ceramic or glass core, ensuring stable and precise temperature measurement. Their function is based on the predictable increase in electrical resistance of the metal wire as temperature rises, providing high accuracy and repeatability over a wide temperature range. Unlike thermistors, RTDs offer superior linearity and stability, making them ideal for industrial applications requiring precise temperature control.

Key Differences Between Thermistors and RTDs

Thermistors are temperature sensors made from semiconductor materials with a nonlinear resistance-temperature relationship, offering high sensitivity at lower temperatures but limited accuracy over wide ranges. RTDs (Resistance Temperature Detectors) use pure metals like platinum, providing a nearly linear resistance change with temperature, superior accuracy, and stability across broader temperature ranges. Unlike thermistors, RTDs excel in precision applications despite higher costs and slower response times.

Accuracy and Precision Comparison

RTDs (Resistance Temperature Detectors) offer higher accuracy and precision than thermistors due to their stable resistance-temperature relationship and minimal drift over time, often achieving accuracy within +-0.1degC. Thermistors, although highly sensitive with rapid response times, typically exhibit less precision and accuracy, varying between +-0.2degC to +-1degC depending on the type and range. In applications requiring stringent temperature control and long-term stability, RTDs are preferred, while thermistors suit cost-sensitive or rapid-response environments.

Temperature Range and Stability Analysis

Thermistors typically operate effectively within a temperature range of -50degC to 150degC, offering high sensitivity but less stability over time compared to RTDs. RTDs function well in a broader temperature range from -200degC to 850degC, providing superior long-term stability and accuracy due to their metallic sensing element. Stability analysis shows RTDs maintain consistent resistance values under varying temperatures, making them ideal for precision applications requiring reliable readings over extended periods.

Response Time: Thermistor vs RTD

Thermistors generally exhibit faster response times, often in the range of milliseconds, due to their smaller size and lower thermal mass. RTDs, while more accurate over a wide temperature range, typically have slower response times, often measured in seconds, because of their larger sensing elements and protective housings. Choosing between a thermistor and an RTD depends on the required balance between speed and accuracy in temperature measurement applications.

Applications and Use Cases in Industry

Thermistors are widely used in applications requiring fast response and precise temperature measurements within a limited range, such as in HVAC systems, automotive temperature control, and consumer electronics. RTDs (Resistance Temperature Detectors) are preferred in industrial process control, aerospace, and food processing due to their high accuracy, stability, and ability to operate over a wider temperature range. Industries rely on thermistors for cost-effective, short-term monitoring, while RTDs are deployed in critical environments demanding long-term reliability and precision.

Cost Considerations and Economic Factors

Thermistors generally offer lower initial costs compared to RTDs, making them suitable for budget-sensitive applications requiring precise temperature measurements within a limited range. RTDs, while more expensive upfront due to their construction and materials such as platinum, provide higher accuracy, stability, and longevity, resulting in reduced maintenance costs over time. Economic factors also favor RTDs in industrial settings where long-term reliability and repeatability can offset the higher capital investment.

Choosing the Right Sensor: Thermistor vs RTD

Choosing the right sensor depends on the application's temperature range and accuracy requirements; thermistors offer high sensitivity and fast response for temperatures typically between -50degC and 150degC, making them ideal for precise measurements in limited ranges. RTDs provide superior accuracy, stability, and linearity over a broader temperature range of -200degC to 850degC, suitable for industrial environments requiring long-term reliability. Cost considerations also influence selection, with thermistors generally being more affordable but less durable than the more expensive, robust RTDs.

Resistance Temperature Detector (RTD)

Resistance Temperature Detectors (RTDs) offer higher accuracy, stability, and a wider temperature range than thermistors, making them ideal for precise industrial temperature measurements.

Negative Temperature Coefficient (NTC)

NTC thermistors exhibit a rapid decrease in resistance with increasing temperature, making them highly sensitive for precise temperature measurements compared to RTDs.

Positive Temperature Coefficient (PTC)

Thermistors with Positive Temperature Coefficient (PTC) exhibit a sharp increase in resistance as temperature rises, making them ideal for overcurrent protection, whereas RTDs provide gradual resistance changes with higher accuracy for precise temperature measurement.

Platinum Resistance Sensor

Platinum Resistance Sensors (RTDs) provide superior temperature accuracy and stability compared to thermistors, making them ideal for precise industrial temperature measurements.

Thermistor Beta Value

Thermistor Beta Value represents the sensitivity of the thermistor's resistance to temperature changes, typically ranging between 3000 and 4500 K, making it crucial for precise temperature measurement compared to the linear resistance-temperature relationship of RTDs.

Wheatstone Bridge Circuit

Thermistors offer higher sensitivity and faster response in Wheatstone bridge circuits for temperature measurement, while RTDs provide superior accuracy and stability over a wider temperature range.

Temperature Coefficient of Resistance

Thermistors typically have a high negative temperature coefficient of resistance (NTC) around -4% to -5% per degC, whereas RTDs possess a positive temperature coefficient of resistance (PTC) approximately 0.00385 O/O/degC for platinum sensors.

Self-Heating Error

Thermistors exhibit higher self-heating errors than RTDs due to their greater electrical resistance and power dissipation, impacting temperature measurement accuracy.

Thermal Time Constant

RTDs generally have a longer thermal time constant than thermistors, resulting in slower temperature response but greater stability and accuracy.

Lead Wire Compensation

Lead wire compensation is crucial for accurate temperature measurement in RTDs due to their low resistance sensitivity, whereas thermistors typically require less compensation because of their higher resistance values.

Thermistor vs RTD Infographic

njnir.com

njnir.com