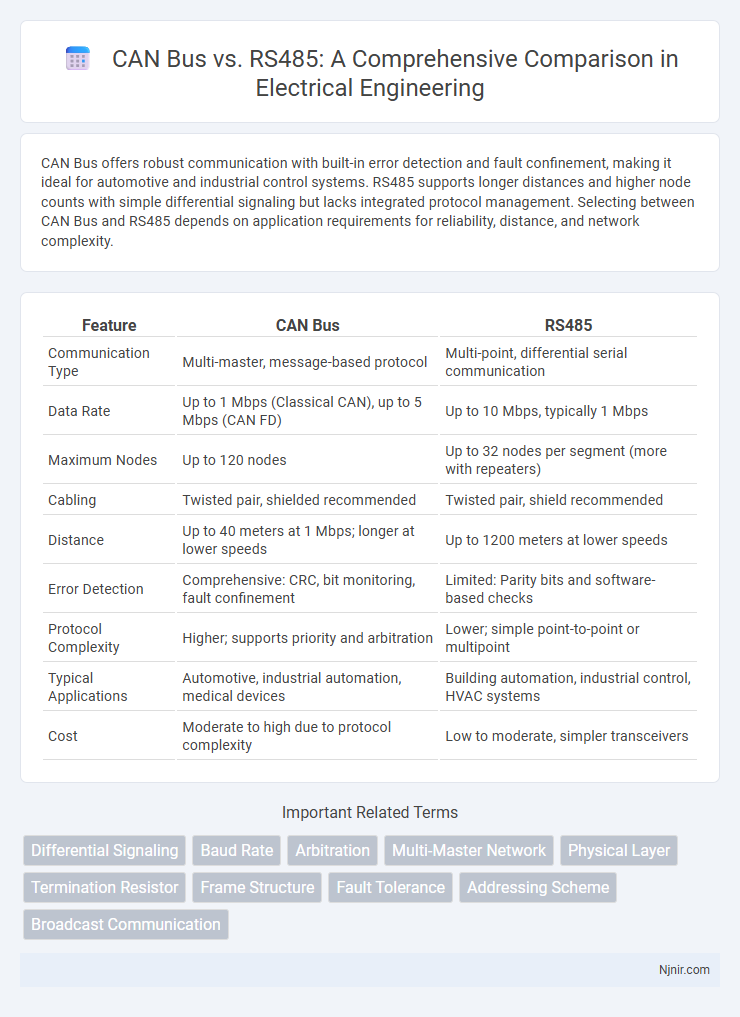

CAN Bus offers robust communication with built-in error detection and fault confinement, making it ideal for automotive and industrial control systems. RS485 supports longer distances and higher node counts with simple differential signaling but lacks integrated protocol management. Selecting between CAN Bus and RS485 depends on application requirements for reliability, distance, and network complexity.

Table of Comparison

| Feature | CAN Bus | RS485 |

|---|---|---|

| Communication Type | Multi-master, message-based protocol | Multi-point, differential serial communication |

| Data Rate | Up to 1 Mbps (Classical CAN), up to 5 Mbps (CAN FD) | Up to 10 Mbps, typically 1 Mbps |

| Maximum Nodes | Up to 120 nodes | Up to 32 nodes per segment (more with repeaters) |

| Cabling | Twisted pair, shielded recommended | Twisted pair, shield recommended |

| Distance | Up to 40 meters at 1 Mbps; longer at lower speeds | Up to 1200 meters at lower speeds |

| Error Detection | Comprehensive: CRC, bit monitoring, fault confinement | Limited: Parity bits and software-based checks |

| Protocol Complexity | Higher; supports priority and arbitration | Lower; simple point-to-point or multipoint |

| Typical Applications | Automotive, industrial automation, medical devices | Building automation, industrial control, HVAC systems |

| Cost | Moderate to high due to protocol complexity | Low to moderate, simpler transceivers |

Overview of CAN Bus and RS485

CAN Bus is a robust vehicle bus standard designed to allow microcontrollers and devices to communicate without a host computer, utilizing a multi-master, message-oriented protocol that supports real-time control applications. RS485 is a standard defining the electrical characteristics of drivers and receivers for balanced digital multipoint systems, enabling long-distance and high-speed serial communication in industrial environments. Both protocols support multi-node communication but differ in error handling, data framing, and typical application domains such as automotive for CAN and industrial automation for RS485.

Key Differences Between CAN Bus and RS485

CAN Bus offers advanced error detection and fault confinement mechanisms, making it ideal for automotive and industrial applications requiring high reliability. RS485 supports simpler multi-point communication with longer cable lengths and higher noise immunity but lacks built-in message arbitration and error handling. While CAN Bus uses a message-based protocol with identifiers for prioritized communication, RS485 operates with basic differential signaling without standardized data framing or addressing.

Communication Protocols: CAN Bus vs RS485

CAN Bus communication protocol offers robust error detection and prioritization, enabling reliable data transmission in automotive and industrial environments through message-based arbitration. RS485 protocol utilizes differential signaling for long-distance, multipoint communication but lacks built-in error handling and message prioritization, requiring additional software layers for protocol management. The choice between CAN Bus and RS485 depends on the need for network complexity, fault tolerance, and real-time control capabilities in specific applications.

Data Transmission Speeds and Efficiency

CAN Bus supports data transmission speeds up to 1 Mbps, optimizing real-time communication with efficient error detection and arbitration mechanisms. RS485 offers variable speeds typically up to 10 Mbps over short distances, but its efficiency decreases in complex network topologies due to lack of built-in error handling. CAN Bus excels in reliable multi-node environments, making it superior for automotive and industrial control systems requiring consistent data integrity.

Network Topology and Scalability

CAN Bus utilizes a multi-master, broadcast topology that supports up to 120 nodes on a single network segment, ideal for automotive and industrial applications requiring robust error detection and real-time communication. RS485 employs a differential, half-duplex bus topology commonly supporting up to 32 devices on a single segment, easily extended using repeaters to increase network length and device count. Scalability favors CAN Bus in systems demanding complex, noise-resistant multi-node communication, while RS485 excels in simpler, longer-distance networks with moderate device counts.

Error Detection and Fault Tolerance

CAN Bus employs advanced error detection mechanisms including cyclic redundancy checks (CRC), bit stuffing, and acknowledgement slots, enabling automatic retransmission of corrupted frames to ensure data integrity. RS485, while robust for long-distance serial communication, relies primarily on parity checks and timeout mechanisms, offering limited error detection capabilities compared to CAN Bus. CAN Bus offers superior fault tolerance through multiple error counters and error confinement strategies, allowing nodes to enter error passive or bus-off states, enhancing network reliability in noisy environments.

Application Areas in Electrical Engineering

CAN Bus is widely used in automotive electronics, industrial automation, and building management systems due to its robustness in noisy environments and efficient multi-master communication. RS485 excels in long-distance communication for industrial control systems, motor drives, and SCADA networks, leveraging its differential signaling for high noise immunity. Both protocols support distributed control but differ in application focus: CAN Bus suits complex, time-critical systems while RS485 is preferred for simple, point-to-point or multi-drop network configurations.

Installation and Maintenance Considerations

CAN Bus systems require twisted pair cables with proper termination resistors at both ends to prevent signal reflections, simplifying installation and ensuring reliable data transmission. RS485 installations often need bus topology wiring with careful attention to grounding and termination to avoid noise and data errors. Maintenance for CAN Bus is typically easier due to its built-in error detection and fault confinement features, while RS485 systems may require more manual troubleshooting and periodic resistance checks to maintain network integrity.

Cost and Component Availability

CAN Bus typically incurs higher costs due to the need for specialized transceivers and controllers, but it benefits from widespread automotive industry adoption, ensuring robust component availability. RS485 offers a lower-cost solution with simpler transceiver requirements and broadly available components ideal for industrial and building automation. While RS485 components are generally more economical and accessible, CAN Bus's comprehensive ecosystem provides greater long-term support and reliability for complex networked systems.

Choosing Between CAN Bus and RS485

Choosing between CAN Bus and RS485 depends on the application's requirements for data integrity, speed, and network complexity. CAN Bus offers robust error detection, high communication speed up to 1 Mbps, and is ideal for automotive and industrial environments requiring real-time control and diagnostics. RS485 supports longer cable lengths up to 1200 meters with slower speeds around 10 Mbps at short distances, making it suitable for simple, long-distance serial communication in building automation and industrial equipment.

Differential Signaling

CAN Bus and RS485 both use differential signaling for noise immunity, but CAN Bus integrates error detection and message arbitration, enhancing communication reliability in automotive and industrial networks.

Baud Rate

CAN Bus supports baud rates up to 1 Mbps optimized for automotive environments, while RS485 can achieve higher baud rates exceeding 10 Mbps over shorter distances in industrial applications.

Arbitration

CAN Bus uses nondestructive bitwise arbitration enabling real-time message priority handling, while RS485 relies on external protocols for collision avoidance without inherent arbitration mechanisms.

Multi-Master Network

CAN Bus supports a robust multi-master network with collision detection and automatic arbitration, enabling multiple devices to communicate simultaneously, whereas RS485 typically requires a master-slave architecture or additional protocols to manage multi-master communication.

Physical Layer

CAN Bus uses a differential two-wire system with twisted pair cables and specific termination resistors to reduce noise and support reliable data transmission, while RS485 also employs a differential signaling method with balanced lines but allows longer cable lengths and simpler wiring for multi-point communication in industrial environments.

Termination Resistor

CAN Bus requires termination resistors of 120 ohms at each end of the bus to minimize signal reflections, whereas RS485 typically uses 120-ohm termination resistors only at the two endpoints of the network to ensure signal integrity.

Frame Structure

CAN Bus frame structure includes arbitration ID, control bits, data field (0-8 bytes), CRC, and acknowledge bits for efficient real-time communication, while RS485 uses a simpler frame with start bit, data bits (typically 8), parity bit, and stop bits focused on basic serial data transmission.

Fault Tolerance

CAN Bus offers superior fault tolerance with built-in error detection and retransmission mechanisms compared to RS485, which relies on simpler error checking and lacks robust fault-handling features.

Addressing Scheme

CAN Bus uses a message-based identifier system for addressing that allows multiple nodes to communicate without unique addresses, while RS485 requires explicit device addressing in its protocol layer to distinguish nodes on the bus.

Broadcast Communication

CAN Bus enables efficient broadcast communication by allowing all connected nodes to receive messages simultaneously on a multi-master network, while RS485 primarily supports point-to-point or multi-drop communication without inherent broadcast capabilities.

CAN Bus vs RS485 Infographic

njnir.com

njnir.com