High-side switching connects the load to the positive supply voltage, enabling control of the supply line, which is beneficial for protecting against short circuits and ensuring safer operation in certain applications. Low-side switching grounds the load by connecting it to the negative or ground line, offering simpler circuit design and easier implementation but may pose higher risks if load isolation is critical. Choosing between high-side and low-side switching depends on factors such as load type, voltage levels, safety requirements, and the need for accurate current sensing.

Table of Comparison

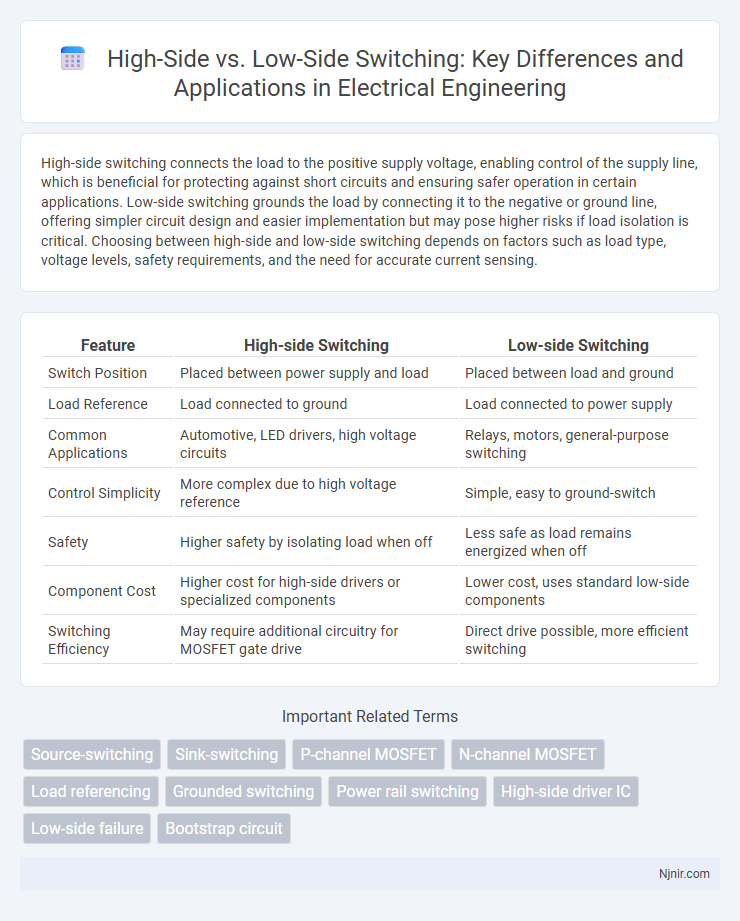

| Feature | High-side Switching | Low-side Switching |

|---|---|---|

| Switch Position | Placed between power supply and load | Placed between load and ground |

| Load Reference | Load connected to ground | Load connected to power supply |

| Common Applications | Automotive, LED drivers, high voltage circuits | Relays, motors, general-purpose switching |

| Control Simplicity | More complex due to high voltage reference | Simple, easy to ground-switch |

| Safety | Higher safety by isolating load when off | Less safe as load remains energized when off |

| Component Cost | Higher cost for high-side drivers or specialized components | Lower cost, uses standard low-side components |

| Switching Efficiency | May require additional circuitry for MOSFET gate drive | Direct drive possible, more efficient switching |

Introduction to High-side and Low-side Switching

High-side switching involves placing the switching device between the power supply and the load, enabling control of the positive voltage rail, which is essential for sources with common ground references. Low-side switching positions the switch between the load and ground, simplifying circuit design and often used in applications where the load connects directly to the supply voltage. Understanding the configuration of high-side versus low-side switching is critical for optimizing safety, efficiency, and compatibility in power electronics and control systems.

Fundamental Concepts of Switch Placement

High-side switching places the switch between the power supply and the load, allowing the load to be connected directly to ground, which helps in protecting the circuit from unwanted current paths and simplifies grounding issues. Low-side switching positions the switch between the load and ground, making the load always connected to the supply voltage, useful for simple control but potentially causing grounding problems and noise in sensitive circuits. Understanding these fundamental switch placements is critical for designing efficient and safe electronic circuits, balancing control complexity, noise immunity, and system protection.

Understanding High-side Switching

High-side switching involves controlling the load by connecting it to the positive supply voltage, enabling the switch to source current directly to the load, which is essential for applications requiring load voltage monitoring and safety isolation. This method uses P-channel MOSFETs or PNP transistors for easier integration in positive voltage rails, making it preferable in automotive and industrial systems where ground reference is critical. Understanding the control logic and voltage level requirements for high-side drivers is crucial for optimizing efficiency and protecting the circuit from short circuits and overcurrent conditions.

Understanding Low-side Switching

Low-side switching controls the load by connecting its terminal to ground, allowing current to flow from the positive supply through the load to the switch. It is simpler to implement and cost-effective, often used in applications where the load is grounded and the switching device can safely handle the ground return path. This method ensures easier control with standard NPN transistors or N-channel MOSFETs but may cause issues with ground reference shifts in sensitive circuits.

Key Differences Between High-side and Low-side Switching

High-side switching connects the load to the positive voltage supply, enabling control of the power source side, while low-side switching connects the load to ground, controlling the return path. High-side switches typically offer better load protection and reduced ground noise but require more complex driver circuits, whereas low-side switches are simpler and more cost-effective but may introduce ground disturbances. The choice between high-side and low-side switching depends on the application's voltage levels, safety considerations, and noise immunity requirements.

Advantages of High-side Switching

High-side switching offers enhanced safety by connecting the load to the positive supply, reducing the risk of short circuits and electrical faults. It allows for easier grounding of the load, facilitating better control and protection in automotive and industrial applications. This method also supports controlling multiple loads independently while maintaining a common ground reference, improving system reliability and design flexibility.

Advantages of Low-side Switching

Low-side switching offers simpler circuit design and easier control by grounding the load, reducing component costs and complexity. It enhances safety by isolating the control circuitry from the supply voltage and minimizes voltage spikes due to lower switching noise. This method is widely preferred in applications requiring efficient load control with straightforward implementation, such as in automotive and industrial systems.

Common Applications for High-side and Low-side Switching

High-side switching is commonly used in automotive and industrial applications where the load needs to be connected to the positive supply voltage, such as in controlling LED lights or power relays. Low-side switching is frequently employed in consumer electronics and microcontroller interfacing, providing a ground path for loads like motors and solenoids. Selecting the appropriate switch type depends on load requirements, safety considerations, and the electrical environment.

Design Considerations and Challenges

High-side switching involves placing the switch between the power supply and the load, which requires components that can handle higher voltage levels and often necessitates level shifting for control signals, posing design challenges in driver circuitry. Low-side switching positions the switch between the load and ground, simplifying driver requirements but potentially causing issues with grounding noise and load referencing. Designers must carefully evaluate factors like voltage levels, noise susceptibility, switching speed, and thermal management to select the optimal configuration for specific applications.

Choosing the Right Switching Method for Your Circuit

High-side switching connects the load to the positive supply voltage, providing better protection against short circuits and enabling easier control of the load's ground reference. Low-side switching connects the load to ground, simplifying the design and reducing cost but may expose the load to ground potential fluctuations. Selecting between high-side and low-side switching hinges on factors like voltage level, load type, protection requirements, and overall circuit safety to ensure optimal performance and reliability.

Source-switching

High-side source-switching connects the load to ground through the switch, offering better protection and reduced noise compared to low-side switching, which switches the supply voltage and can cause ground reference inconsistencies.

Sink-switching

Sink-switching involves low-side switching where the load connects to the positive voltage and the switch completes the circuit by connecting the load to ground.

P-channel MOSFET

P-channel MOSFETs are commonly used in high-side switching to simplify load control by connecting the source to the positive supply voltage, enabling efficient switching without the need for level shifting.

N-channel MOSFET

High-side switching with N-channel MOSFETs requires a gate voltage higher than the supply voltage for proper operation, while low-side switching drives the MOSFET gate relative to ground, enabling easier control and simpler gate drive circuitry.

Load referencing

High-side switching references the load to ground for improved safety and noise immunity, while low-side switching references the load to the supply voltage, simplifying control but potentially causing ground disturbances.

Grounded switching

Grounded switching in low-side switching connects the load's negative terminal to ground, enabling easier control and safer fault conditions compared to high-side switching, which switches the positive supply line.

Power rail switching

High-side switching controls the positive power rail to supply voltage to the load while low-side switching connects the load to ground to complete the circuit, with high-side preferred for safer load isolation and low-side valued for simpler control and cost-efficiency.

High-side driver IC

High-side driver ICs enable efficient control of power supply lines by switching the positive voltage rail, providing improved load protection and simpler ground referencing compared to low-side switching methods.

Low-side failure

Low-side switching failures often result from damaged ground paths or faulty transistors, causing device malfunction by preventing proper current flow to the load.

Bootstrap circuit

A bootstrap circuit in high-side switching enables efficient gate drive voltage for N-channel MOSFETs by temporarily storing charge, whereas low-side switching typically does not require a bootstrap due to its ground-referenced load connection.

High-side vs Low-side Switching Infographic

njnir.com

njnir.com