A panel meter is designed for fixed installation to continuously display electrical parameters such as voltage, current, or frequency within control panels, offering real-time monitoring. Digital multimeters provide portable, versatile measurement capabilities for voltage, current, resistance, and other electrical properties, suitable for troubleshooting and precise diagnostics. Panel meters excel in permanent monitoring setups, while digital multimeters are preferred for flexibility and detailed analysis in various electrical engineering applications.

Table of Comparison

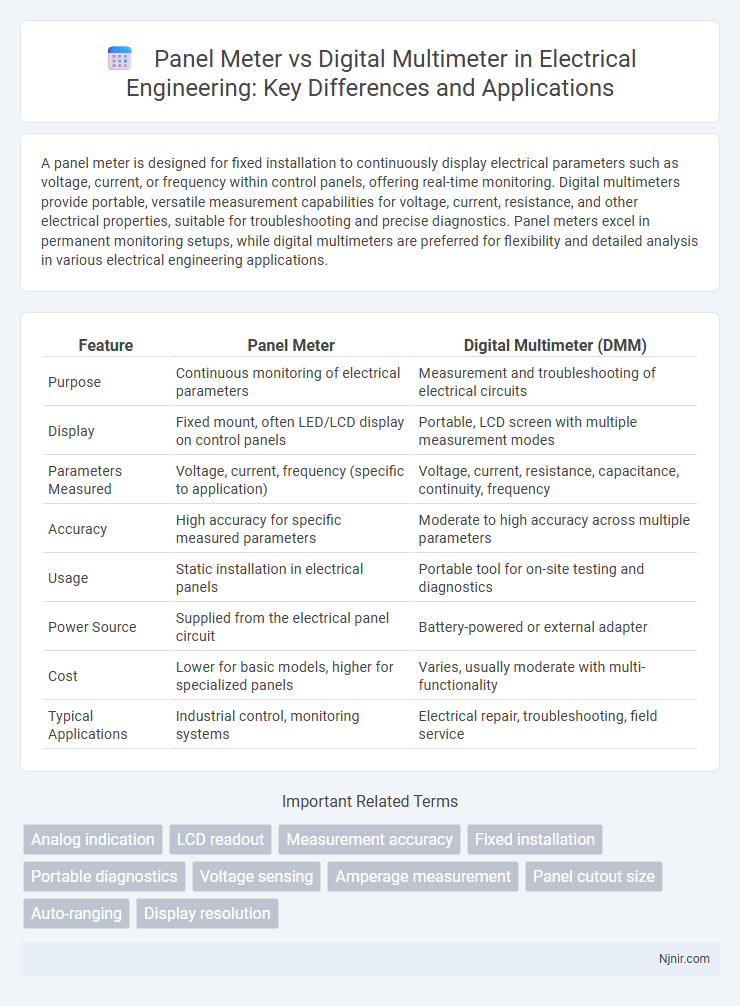

| Feature | Panel Meter | Digital Multimeter (DMM) |

|---|---|---|

| Purpose | Continuous monitoring of electrical parameters | Measurement and troubleshooting of electrical circuits |

| Display | Fixed mount, often LED/LCD display on control panels | Portable, LCD screen with multiple measurement modes |

| Parameters Measured | Voltage, current, frequency (specific to application) | Voltage, current, resistance, capacitance, continuity, frequency |

| Accuracy | High accuracy for specific measured parameters | Moderate to high accuracy across multiple parameters |

| Usage | Static installation in electrical panels | Portable tool for on-site testing and diagnostics |

| Power Source | Supplied from the electrical panel circuit | Battery-powered or external adapter |

| Cost | Lower for basic models, higher for specialized panels | Varies, usually moderate with multi-functionality |

| Typical Applications | Industrial control, monitoring systems | Electrical repair, troubleshooting, field service |

Introduction to Panel Meters and Digital Multimeters

Panel meters are specialized instruments designed to display electrical measurements such as voltage, current, or frequency on a fixed panel, providing real-time data visualization for monitoring systems. Digital multimeters (DMMs) offer versatile measurement capabilities, including voltage, current, resistance, and continuity, with enhanced digital accuracy and portability for diagnostic applications. Both devices play crucial roles in electrical engineering, with panel meters favored for continuous monitoring and DMMs utilized for precise troubleshooting and testing.

Basic Principles of Operation

A panel meter operates by converting an electrical signal into a proportional mechanical movement, typically using a moving coil or shunt resistor to display voltage, current, or frequency on a fixed scale. In contrast, a digital multimeter employs analog-to-digital conversion techniques to measure electrical parameters, providing precise numerical readouts on an LCD screen. Panel meters are suited for continuous monitoring with simplistic displays, whereas digital multimeters deliver versatile, portable measurement capabilities with higher accuracy and multiple functions.

Key Features and Specifications

Panel meters offer real-time visual monitoring of specific electrical parameters like voltage, current, or frequency with high accuracy and a fixed display type, often LED or LCD, tailored for permanent installation in control panels. Digital multimeters provide versatile measurements including voltage, current, resistance, and continuity, featuring multiple functions in a handheld device with a digital display and auto-ranging capability for broader diagnostic applications. Panel meters generally emphasize durability and continuous operation in industrial environments, while digital multimeters prioritize portability, multifunctionality, and user convenience for field troubleshooting.

Types and Applications

Panel meters include analog and digital types primarily used for fixed installations in control panels to display electrical parameters such as voltage, current, and frequency. Digital multimeters (DMMs) offer versatile handheld functionality with multiple measurement modes, including voltage, current, resistance, continuity, and capacitance, making them suitable for troubleshooting, testing, and maintenance across electronics, automotive, and industrial sectors. While panel meters excel in continuous monitoring within operational systems, digital multimeters provide portable, comprehensive diagnostic capability for field and lab environments.

Accuracy and Measurement Range

Panel meters typically offer high accuracy within a limited measurement range optimized for specific parameters such as voltage, current, or frequency, making them ideal for continuous monitoring in industrial applications. Digital multimeters provide broader measurement ranges, capable of measuring voltage, current, resistance, capacitance, and temperature with variable accuracy depending on the model and setting. While digital multimeters excel in versatility and portability, panel meters generally deliver more stable readings for targeted metrics due to dedicated circuitry and calibration.

Display and User Interface Comparison

Panel meters feature fixed, easy-to-read displays with limited parameters, designed for continuous monitoring in industrial settings, whereas digital multimeters offer versatile, multi-functional interfaces with digital LCD screens capable of displaying various measurement types. Digital multimeters provide user-friendly interfaces with buttons and rotary switches for mode selection, enabling detailed diagnostics, while panel meters prioritize simplicity and clarity for specific parameter readouts. The display resolution and update rates in digital multimeters generally surpass those of panel meters, enhancing measurement precision and user interaction.

Installation and Portability

Panel meters are designed for fixed installation within control panels, offering a compact and integrated display solution that requires wiring and mounting, making them less portable but ideal for continuous monitoring. Digital multimeters feature handheld designs with battery power, providing high portability and ease of use across multiple measurement points without permanent setup. Their portability allows technicians to quickly test voltage, current, and resistance on-site, while panel meters excel in providing permanent, real-time readings in industrial environments.

Maintenance and Calibration Needs

Panel meters typically require less frequent calibration and minimal maintenance due to their fixed installation and specific measurement functions, making them ideal for continuous monitoring in industrial environments. Digital multimeters demand regular calibration and more frequent maintenance to ensure accuracy across diverse measurement tasks, including voltage, current, and resistance testing. Proper scheduling of calibration for both devices is crucial for maintaining precise readings and reliable performance in electrical and electronic applications.

Cost and Lifecycle Analysis

Panel meters generally have a lower initial cost compared to digital multimeters, making them cost-effective for fixed monitoring applications. Digital multimeters, while more expensive upfront, offer versatility and extended functionality that can reduce total lifecycle costs through less frequent replacements and maintenance. Evaluating long-term operational expenses, including calibration and durability, reveals that digital multimeters provide a better return on investment in dynamic or multi-parameter measurement environments.

Choosing the Right Instrument for Your Application

Selecting between a panel meter and a digital multimeter depends on the specific measurement needs and context of use. Panel meters provide continuous, real-time monitoring of a single electrical parameter such as voltage or current, ideal for embedded systems and industrial control panels. Digital multimeters offer versatile functionality for measuring voltage, current, resistance, and more, suitable for troubleshooting, maintenance, and versatile field applications.

Analog indication

Panel meters provide continuous analog indication with a needle display for real-time monitoring, whereas digital multimeters offer numerical readouts without analog needle visualization.

LCD readout

Panel meters feature fixed, large LCD readouts for continuous monitoring, while digital multimeters offer versatile, smaller LCD screens optimized for multi-parameter measurements and portability.

Measurement accuracy

Panel meters typically offer higher measurement accuracy due to their dedicated analog or digital displays specifically calibrated for precise readings, while digital multimeters provide versatile measurement functions with slightly lower accuracy across varying ranges.

Fixed installation

Panel meters provide continuous, fixed installation measurements with easy integration into control panels, whereas digital multimeters are handheld, portable tools suited for flexible, multi-purpose testing rather than permanent setups.

Portable diagnostics

Digital multimeters offer superior portability and multifunctional diagnostics compared to fixed panel meters, making them ideal for on-the-go electrical testing and troubleshooting.

Voltage sensing

Panel meters provide continuous voltage monitoring with fixed display accuracy, while digital multimeters offer versatile voltage measurements with higher precision and selectable ranges.

Amperage measurement

Digital multimeters provide versatile and precise amperage measurement across a wide range, while panel meters offer continuous real-time current monitoring with easier integration into control systems.

Panel cutout size

Panel meters typically require a standardized panel cutout size of 48x96 mm or 72x72 mm to fit securely, whereas digital multimeters do not require a panel cutout as they are handheld devices.

Auto-ranging

Digital multimeters feature auto-ranging capabilities that automatically adjust measurement scales for voltage, current, and resistance, whereas traditional panel meters typically require manual range selection.

Display resolution

Panel meters offer fixed, often lower display resolution optimized for specific measurement ranges, while digital multimeters provide higher display resolution with multiple digits for detailed and versatile measurement readings.

panel meter vs digital multimeter Infographic

njnir.com

njnir.com