Sensor-based control in electrical engineering provides precise rotor position feedback through physical sensors, enhancing accuracy in motor performance and enabling smoother operation. Sensorless control eliminates the need for sensors by estimating rotor position using algorithms and motor parameters, reducing system cost and complexity while improving reliability in harsh environments. Both methods offer distinct advantages, with sensor-based control excelling in precision applications and sensorless control preferred for cost-sensitive or rugged conditions.

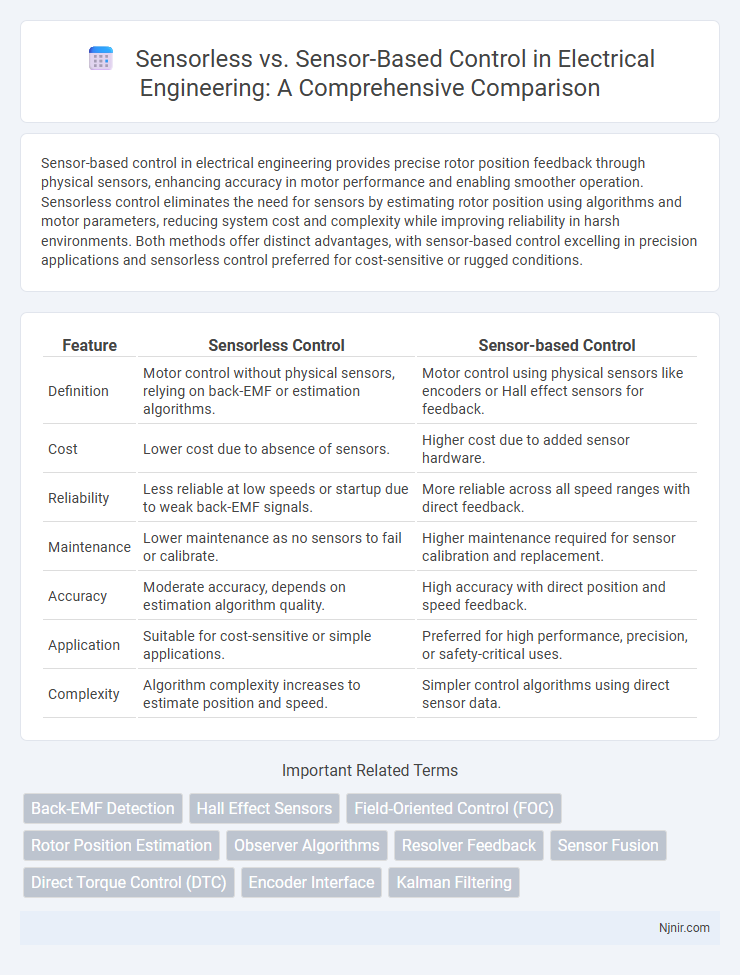

Table of Comparison

| Feature | Sensorless Control | Sensor-based Control |

|---|---|---|

| Definition | Motor control without physical sensors, relying on back-EMF or estimation algorithms. | Motor control using physical sensors like encoders or Hall effect sensors for feedback. |

| Cost | Lower cost due to absence of sensors. | Higher cost due to added sensor hardware. |

| Reliability | Less reliable at low speeds or startup due to weak back-EMF signals. | More reliable across all speed ranges with direct feedback. |

| Maintenance | Lower maintenance as no sensors to fail or calibrate. | Higher maintenance required for sensor calibration and replacement. |

| Accuracy | Moderate accuracy, depends on estimation algorithm quality. | High accuracy with direct position and speed feedback. |

| Application | Suitable for cost-sensitive or simple applications. | Preferred for high performance, precision, or safety-critical uses. |

| Complexity | Algorithm complexity increases to estimate position and speed. | Simpler control algorithms using direct sensor data. |

Introduction to Motion Control in Electrical Engineering

Sensorless control in electrical engineering motion control eliminates the need for physical sensors by estimating rotor position and speed using mathematical models and algorithms, reducing system cost and complexity. Sensor-based control relies on devices such as encoders or Hall effect sensors to provide real-time feedback for precise motor operation and improved dynamic performance. Both methods play critical roles in applications requiring varying degrees of accuracy, reliability, and cost-efficiency in electric motor control.

Overview of Sensor-based Control Systems

Sensor-based control systems utilize physical devices such as encoders, resolvers, and Hall-effect sensors to provide real-time feedback on motor position, speed, and torque, enabling precise and accurate control. These systems enhance performance in applications requiring high reliability and dynamic response, particularly in robotics, CNC machines, and electric vehicles. The integration of sensors ensures stable operation under varying load conditions by directly monitoring motor parameters, though it introduces additional cost and complexity.

Fundamentals of Sensorless Control Techniques

Sensorless control techniques estimate rotor position and speed by analyzing stator voltage and current signals, eliminating the need for physical sensors. These methods rely on mathematical models, such as back-EMF estimation, observer-based algorithms, and model reference adaptive systems, to achieve accurate rotor position detection. The absence of sensors reduces hardware costs, increases system reliability, and improves robustness in harsh environments.

Comparative Benefits of Sensor-based and Sensorless Approaches

Sensor-based control offers precise rotor position and speed feedback, enabling accurate and efficient motor performance under varying load conditions. Sensorless control eliminates the need for physical sensors, reducing cost, maintenance, and improving system reliability in harsh environments. While sensor-based methods excel in dynamic response and low-speed operation, sensorless approaches provide robust solutions for applications with moderate speed ranges and cost constraints.

Key Applications: Where Sensor-based Control Excels

Sensor-based control excels in high-precision applications such as robotics, aerospace, and industrial automation, where accurate position and speed feedback is critical for performance and safety. It is essential in environments requiring real-time monitoring and adaptive control, including electric vehicle traction systems and CNC machines. The integration of sensors enables enhanced reliability, precise torque control, and reduced risk of system instability under varying load conditions.

Key Applications: Where Sensorless Control is Preferred

Sensorless control is preferred in applications such as electric vehicles, industrial pumps, and HVAC systems where cost reduction, reliability, and maintenance savings are critical. This method eliminates the need for physical sensors, reducing hardware complexity and improving system robustness in harsh environments. It is particularly advantageous in high-speed motors and applications requiring compact design or where sensor installation is impractical.

Accuracy and Reliability in Motion Control

Sensor-based control in motion systems offers high accuracy by directly measuring rotor position and speed, enabling precise feedback and real-time adjustments. Sensorless control relies on mathematical models and estimation algorithms, which may reduce accuracy due to parameter variations and noise but increases system reliability by eliminating physical sensor failures. Balancing sensorless and sensor-based control depends on application requirements for precision, cost, and environmental robustness in industrial automation.

Cost, Complexity, and Maintenance Considerations

Sensorless control systems minimize upfront costs and reduce mechanical complexity by eliminating physical sensors, resulting in lower maintenance requirements due to fewer components prone to wear or failure. Sensor-based control, while more expensive and complex to implement due to sensor integration, offers higher precision and reliability in real-time feedback, potentially reducing long-term operational risks and costly downtime. When evaluating cost-efficiency, sensorless control is preferable for applications where moderate accuracy suffices, whereas sensor-based systems are advantageous in high-performance environments demanding precise control and thorough diagnostics.

Latest Innovations in Sensorless and Sensor-based Control

Latest innovations in sensorless control harness advanced algorithms and real-time motor parameter estimation to enhance accuracy and efficiency in variable-speed drives, minimizing dependence on physical sensors. Sensor-based control advancements integrate high-resolution encoders and robust feedback systems combined with AI-driven predictive maintenance, improving precision and system reliability in industrial automation. Hybrid approaches increasingly leverage machine learning to optimize control strategies, balancing cost-effectiveness and performance across complex electromechanical applications.

Future Trends and Industry Outlook

Sensorless control techniques are gaining momentum due to cost reduction and enhanced reliability in industrial motor drives, with advancements in high-speed processors and machine learning algorithms improving accuracy and robustness. Sensor-based control remains essential in applications requiring precise position and speed feedback, especially in robotics and aerospace sectors, where safety and performance standards are stringent. The integration of hybrid approaches combining sensorless algorithms with minimal sensor inputs is emerging as a future industry trend, optimizing efficiency while reducing hardware complexity and maintenance costs.

Back-EMF Detection

Back-EMF detection in sensorless control eliminates the need for physical sensors by estimating rotor position through voltage feedback, enhancing reliability and reducing hardware costs compared to sensor-based control systems.

Hall Effect Sensors

Sensorless control eliminates physical Hall Effect sensors by estimating rotor position through back-EMF signals, while sensor-based control relies on Hall Effect sensors to provide precise rotor position feedback for motor commutation.

Field-Oriented Control (FOC)

Sensorless Field-Oriented Control (FOC) optimizes motor efficiency by estimating rotor position through mathematical models, while sensor-based FOC relies on physical sensors like encoders for precise rotor position feedback, enhancing control accuracy in dynamic applications.

Rotor Position Estimation

Sensorless control estimates rotor position using algorithms like back-EMF or observer models, enhancing reliability and reducing cost compared to sensor-based control that relies on physical sensors for precise rotor position feedback.

Observer Algorithms

Observer algorithms in sensorless control estimate rotor position and speed using mathematical models, enabling real-time motor control without physical sensors, whereas sensor-based control relies directly on hardware sensors for accurate feedback.

Resolver Feedback

Resolver feedback in sensor-based control systems provides precise rotor position data, enabling higher accuracy and reliability compared to sensorless control methods that estimate position through back-EMF or mathematical models.

Sensor Fusion

Sensor fusion enhances sensorless and sensor-based control systems by integrating multi-sensor data to improve accuracy, reliability, and real-time performance in applications like robotics and autonomous vehicles.

Direct Torque Control (DTC)

Direct Torque Control (DTC) achieves faster dynamic response and simpler control structure with sensorless methods by estimating rotor position and speed, while sensor-based control relies on precise feedback from physical sensors for higher accuracy and robustness.

Encoder Interface

Sensor-based control with an encoder interface provides precise rotor position feedback enabling accurate motor speed and torque regulation, whereas sensorless control estimates rotor position using back-EMF signals but may suffer from reduced accuracy and slower response under low-speed conditions.

Kalman Filtering

Kalman filtering enhances sensorless control accuracy by estimating system states from noisy measurements, offering real-time adaptive performance compared to traditional sensor-based control reliant on direct physical sensors.

Sensorless vs Sensor-based Control Infographic

njnir.com

njnir.com