Soft starters reduce mechanical stress and electrical surges during motor startup by gradually increasing voltage, enhancing equipment lifespan and energy efficiency. Direct On Line (DOL) starters apply full voltage immediately, causing higher inrush current and mechanical wear but offering simpler design and lower cost. Selecting between soft starters and DOL starters depends on application requirements such as motor size, starting torque, and operational conditions.

Table of Comparison

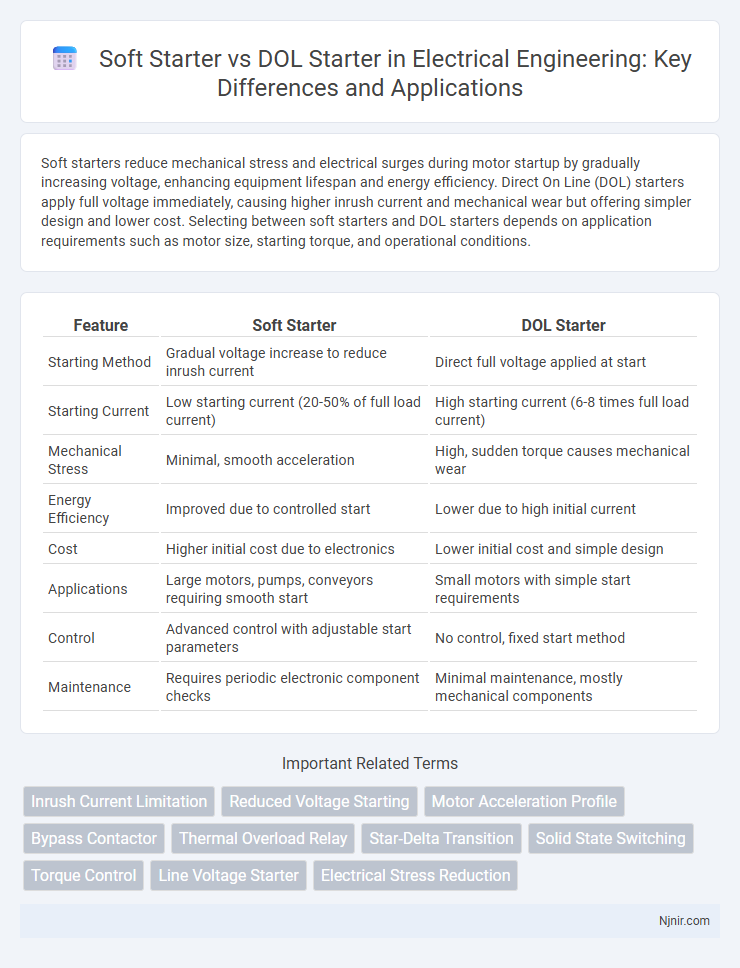

| Feature | Soft Starter | DOL Starter |

|---|---|---|

| Starting Method | Gradual voltage increase to reduce inrush current | Direct full voltage applied at start |

| Starting Current | Low starting current (20-50% of full load current) | High starting current (6-8 times full load current) |

| Mechanical Stress | Minimal, smooth acceleration | High, sudden torque causes mechanical wear |

| Energy Efficiency | Improved due to controlled start | Lower due to high initial current |

| Cost | Higher initial cost due to electronics | Lower initial cost and simple design |

| Applications | Large motors, pumps, conveyors requiring smooth start | Small motors with simple start requirements |

| Control | Advanced control with adjustable start parameters | No control, fixed start method |

| Maintenance | Requires periodic electronic component checks | Minimal maintenance, mostly mechanical components |

Introduction to Motor Starters

Motor starters control the starting current and torque of electric motors, ensuring safe and efficient operation. Soft starters gradually ramp up voltage, reducing mechanical stress and electrical surges, ideal for applications requiring smooth starts. Direct-On-Line (DOL) starters apply full voltage instantly, offering simplicity and cost-effectiveness for small motors without heavy starting loads.

Overview of Soft Starters

Soft starters control the acceleration and deceleration of electric motors by gradually increasing voltage, reducing mechanical stress and electrical peak currents during startup. They offer enhanced motor protection and energy efficiency compared to Direct-On-Line (DOL) starters, which apply full voltage instantly, causing high inrush currents and potential mechanical wear. Commonly used in large industrial motors, soft starters improve operational lifespan and minimize maintenance costs by ensuring smooth motor startups.

Fundamentals of Direct-On-Line (DOL) Starters

Direct-On-Line (DOL) starters provide a simple and cost-effective method for starting electric motors by applying full voltage directly to the motor terminals, resulting in high starting current and torque. They operate through a contactor and overload relay, offering basic motor protection but lack advanced control over starting current or torque. Ideal for small motors with lower starting current requirements, DOL starters are favored in applications where simplicity and low cost outweigh the benefits of reduced mechanical stress.

Working Principle: Soft Starter vs DOL Starter

Soft starters regulate motor voltage by gradually increasing it during startup, reducing mechanical stress and electrical peak currents, thereby ensuring a smooth acceleration. Direct On Line (DOL) starters apply full voltage instantly to the motor, resulting in a sudden surge of current and torque that can cause mechanical and electrical stress. The controlled voltage ramp-up in soft starters enhances motor longevity and energy efficiency compared to the immediate full-voltage application of DOL starters.

Key Differences Between Soft Starter and DOL Starter

Soft starters limit the inrush current and gradually ramp up motor voltage to reduce mechanical stress, while DOL (Direct-On-Line) starters apply full voltage instantly, causing high starting current and torque. Soft starters are suitable for applications requiring smooth start and stop operations to protect equipment, whereas DOL starters are simpler, cost-effective, and ideal for small motors with less starting load. The key differences include current control, mechanical stress, energy efficiency, and overall impact on motor lifespan and maintenance needs.

Advantages of Soft Starters

Soft starters offer precise control of motor starting current, reducing mechanical stress and electrical disturbances compared to Direct-On-Line (DOL) starters. They extend motor lifespan by minimizing inrush current and torque spikes, leading to smoother acceleration and less wear on electrical components. Energy efficiency is improved by optimizing the startup process, resulting in lower operational costs and enhanced reliability in industrial applications.

Advantages of DOL Starters

DOL (Direct On-Line) starters offer simplicity and cost-effectiveness, making them ideal for small motors where reduced starting current is not critical. They provide instant full voltage to the motor, ensuring maximum starting torque and reliable operation in steady load conditions. Maintenance and installation are straightforward due to fewer components, resulting in lower overall operational complexity compared to soft starters.

Typical Applications and Use Cases

Soft starters are typically used in applications requiring controlled starting and stopping to reduce mechanical stress, such as pumps, fans, conveyors, and compressors in industrial and commercial settings. DOL (Direct On-Line) starters are ideal for straightforward, heavy-duty motors where simplicity and cost-effectiveness are priorities, commonly found in small motors, machine tools, and agricultural equipment. Soft starters enhance equipment longevity and energy efficiency by providing smooth acceleration, while DOL starters deliver immediate full voltage for rapid motor startup.

Factors to Consider When Choosing Between Soft Starter and DOL Starter

Factors to consider when choosing between soft starters and DOL starters include motor size, load type, and starting torque requirements. Soft starters provide reduced inrush current and smoother acceleration, making them ideal for large motors or applications sensitive to mechanical stress. DOL starters are simple, cost-effective, and suitable for small motors with high starting torque demands and less concern for electrical impact.

Conclusion: Selecting the Right Starter for Your Application

Choosing between a soft starter and a Direct On-Line (DOL) starter hinges on the specific demands of your application, such as motor size, load characteristics, and the need to minimize mechanical stress. Soft starters provide controlled ramp-up to reduce inrush current and torque, making them ideal for large motors and applications requiring smooth startup and protection. DOL starters are simpler and cost-effective for small motors with less critical startup requirements, offering immediate full voltage start but with higher mechanical and electrical stress.

Inrush Current Limitation

Soft starters limit inrush current by gradually ramping up voltage, reducing mechanical stress and electrical peaks compared to the high inrush current and mechanical shock caused by Direct-On-Line (DOL) starters.

Reduced Voltage Starting

Soft starters reduce electrical and mechanical stress by gradually increasing voltage during motor startup, while DOL starters apply full voltage instantly, causing higher inrush current and torque.

Motor Acceleration Profile

Soft starters provide gradual motor acceleration with reduced inrush current, minimizing mechanical stress and electrical surges compared to the abrupt, full-voltage acceleration of DOL starters.

Bypass Contactor

Soft starters use a bypass contactor to reduce electrical stress by initially limiting current flow, whereas DOL starters lack a bypass contactor and apply full voltage instantly.

Thermal Overload Relay

Soft starters reduce thermal overload relay tripping by gradually increasing motor current, unlike DOL starters which cause sudden current spikes and higher thermal stress.

Star-Delta Transition

Soft starters gradually ramp up motor voltage for smooth startup, whereas DOL starters apply full voltage instantly, with Star-Delta Transition reducing starting current by switching motor connections from star to delta after initial startup.

Solid State Switching

Soft starters use solid-state switching to gradually ramp up motor voltage, reducing mechanical stress and electrical peak currents compared to the direct-on-line (DOL) starter's abrupt full-voltage application.

Torque Control

Soft starters provide precise torque control by gradually ramping up motor voltage, reducing mechanical stress, whereas DOL starters apply full voltage instantly, causing high starting torque and potential mechanical stress.

Line Voltage Starter

Soft starters reduce electrical line voltage gradually during motor startup to minimize inrush current, while DOL starters apply full line voltage instantly, causing higher mechanical stress and electrical spikes.

Electrical Stress Reduction

Soft starters reduce electrical stress by gradually ramping up motor voltage, minimizing inrush current and mechanical wear compared to direct-on-line (DOL) starters that apply full voltage instantly.

soft starter vs DOL starter Infographic

njnir.com

njnir.com