Slip rings provide continuous electrical connection between stationary and rotating parts in AC machines, allowing the transfer of power and signals without interruption. Commutators, used primarily in DC machines, convert the alternating current induced in the armature windings into direct current by mechanically switching the connection between the rotating coil and the external circuit. While slip rings enable smooth rotation with minimal wear, commutators involve brushes that experience more friction and maintenance due to their mechanical switching action.

Table of Comparison

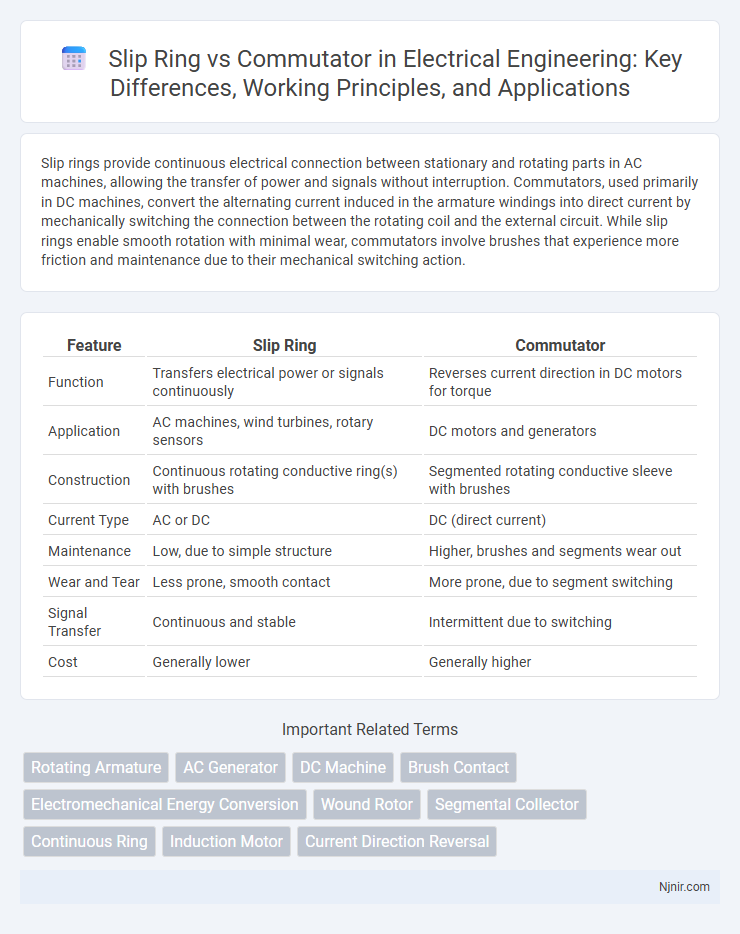

| Feature | Slip Ring | Commutator |

|---|---|---|

| Function | Transfers electrical power or signals continuously | Reverses current direction in DC motors for torque |

| Application | AC machines, wind turbines, rotary sensors | DC motors and generators |

| Construction | Continuous rotating conductive ring(s) with brushes | Segmented rotating conductive sleeve with brushes |

| Current Type | AC or DC | DC (direct current) |

| Maintenance | Low, due to simple structure | Higher, brushes and segments wear out |

| Wear and Tear | Less prone, smooth contact | More prone, due to segment switching |

| Signal Transfer | Continuous and stable | Intermittent due to switching |

| Cost | Generally lower | Generally higher |

Introduction to Slip Rings and Commutators

Slip rings and commutators are critical components in electrical machines that enable the transfer of current between stationary and rotating parts. Slip rings provide uninterrupted AC electrical connection in devices like alternators and wind turbines by maintaining continuous contact through conductive rings and brushes. Commutators, used primarily in DC machines such as motors and generators, convert the alternating current within the armature windings into direct current by mechanically reversing the connection at precise intervals.

Fundamental Working Principles

A slip ring transmits electrical signals and power between stationary and rotating components using continuous rings and brushes, allowing for smooth, uninterrupted rotation. In contrast, a commutator functions as a rotary switch that periodically reverses current direction in a DC motor, ensuring unidirectional torque output. Both devices enable electrical connection in rotating systems, but slip rings maintain constant polarity while commutators manage current reversal.

Key Differences: Slip Ring vs Commutator

Slip rings provide continuous electrical connection for AC signals or power in rotating systems, enabling unidirectional current flow without reversing polarity, whereas commutators serve in DC machines to reverse current direction in the armature windings, ensuring torque consistency. Slip rings consist of simple conductive rings and brushes allowing smooth rotation with minimal wear, while commutators are segmented cylindrical assemblies that mechanically switch current paths. Key differences lie in their applications--slip rings are common in wind turbines and radar systems, while commutators are integral to DC motors and generators.

Construction and Design Features

Slip rings consist of continuous metal rings and stationary brushes that allow the transfer of electrical signals or power in rotating systems, providing smooth and uninterrupted current flow. Commutators, on the other hand, are segmented cylindrical components with insulated metal sections and brushes designed to reverse current direction in DC machines, enabling unidirectional torque. The construction of slip rings emphasizes continuous contact for AC or signal transmission, while commutators focus on segment insulation and precise brush alignment to facilitate current commutation.

Applications in Electrical Machines

Slip rings are primarily used in AC electrical machines such as synchronous motors and wind turbines to transmit power and signals between stationary and rotating parts without interrupting the current. Commutators are typically found in DC machines, including series and shunt motors, facilitating the conversion of AC induced in the armature windings to DC output by mechanical switching. In industrial applications, slip rings enable continuous rotation with electrical connectivity in devices like rotary transformers, while commutators provide precise current direction control essential for speed and torque regulation in DC motors.

Advantages and Disadvantages

Slip rings provide continuous rotation with the ability to transmit AC signals and power efficiently, making them ideal for applications like wind turbines and rotary sensors, but they can suffer from wear and electrical noise over time. Commutators convert AC to DC in universal motors and facilitate current direction reversal, offering precise control but are prone to brush sparking, higher maintenance, and limited rotational speed. Both components impact performance based on factors like electrical conductivity, mechanical reliability, and operational environment, influencing their selection in electrical machinery.

Maintenance and Lifespan Comparison

Slip rings generally require less maintenance than commutators due to their simpler design and fewer contact points, which reduces wear and debris accumulation. Commutators demand frequent inspection and cleaning to prevent brush wear and electrical arcing, impacting their operational lifespan negatively. Consequently, slip rings typically offer longer service life and enhanced reliability in continuous rotation applications compared to commutators.

Common Issues and Troubleshooting

Slip rings often face issues like wear and tear of brushes, electrical noise, and poor contact causing intermittent signal loss, which can be troubleshooted by regular cleaning, lubrication, and replacement of worn brushes. Commutators commonly encounter problems such as carbon build-up, sparking, and uneven wear, leading to motor performance degradation and requiring inspection for brush alignment, thorough cleaning, and resurfacing of the commutator segments. Both components benefit from periodic maintenance schedules, using proper materials for brushes and contacts, and monitoring electrical continuity and noise levels to ensure smooth operation.

Selection Criteria for Industrial Applications

Slip rings are ideal for transmitting power and signals in continuous rotation systems with low to moderate current and voltage, favoring applications requiring smooth and maintenance-free operation. Commutators suit DC machines needing precise current direction control, handling higher currents but requiring regular maintenance due to brush wear. Selection criteria include current capacity, rotational speed, environmental conditions, maintenance capabilities, and the nature of electrical signals required in the industrial application.

Future Trends and Innovations

Slip rings are evolving with innovations such as wireless energy transfer and advanced materials like graphene to enhance conductivity and durability in rotating systems. Commutators are benefiting from precision manufacturing and integration with electronic control systems to reduce wear and improve efficiency in electric motors. Future trends indicate increased adoption of smart sensors and IoT connectivity in both slip rings and commutators for real-time monitoring and predictive maintenance.

Rotating Armature

A slip ring enables continuous electrical connection to a rotating armature for AC signals, while a commutator reverses current direction in a rotating armature to produce unidirectional torque in DC machines.

AC Generator

Slip rings in AC generators provide continuous rotational electrical connection enabling smooth current flow, whereas commutators in DC generators convert AC induced in the armature into unidirectional current.

DC Machine

Slip rings in DC machines provide continuous electrical connection to the armature winding for AC or variable signals, whereas commutators convert armature AC induced voltage to unidirectional DC output by mechanically rectifying current.

Brush Contact

Slip rings maintain continuous brush contact with rotating rings to transfer electrical signals or power, whereas commutators use segmented brushes that periodically make and break contact to convert AC to DC.

Electromechanical Energy Conversion

Slip rings enable continuous rotational electromechanical energy conversion by maintaining unidirectional current flow in AC machines, whereas commutators convert AC induced in the rotor to DC output in DC machines through mechanical switching.

Wound Rotor

In wound rotor systems, slip rings provide continuous electrical connection for external resistors to control starting torque and speed, unlike commutators which mechanically switch current within the rotor.

Segmental Collector

Slip rings provide continuous rotational electrical connections with uniform contact over the entire ring, whereas commutators use segmented collectors to reverse current direction in armature windings for DC motor operation.

Continuous Ring

A slip ring provides continuous rotational electrical connection enabling unlimited rotation, unlike a commutator which interrupts current to convert AC to DC.

Induction Motor

Slip rings in induction motors provide continuous electrical connection for rotor windings enabling smooth AC current flow, whereas commutators are used in DC motors to convert AC to DC by reversing current direction periodically.

Current Direction Reversal

Slip rings maintain continuous current flow without reversing direction in AC systems, whereas commutators mechanically reverse current direction to enable DC motor operation.

slip ring vs commutator Infographic

njnir.com

njnir.com