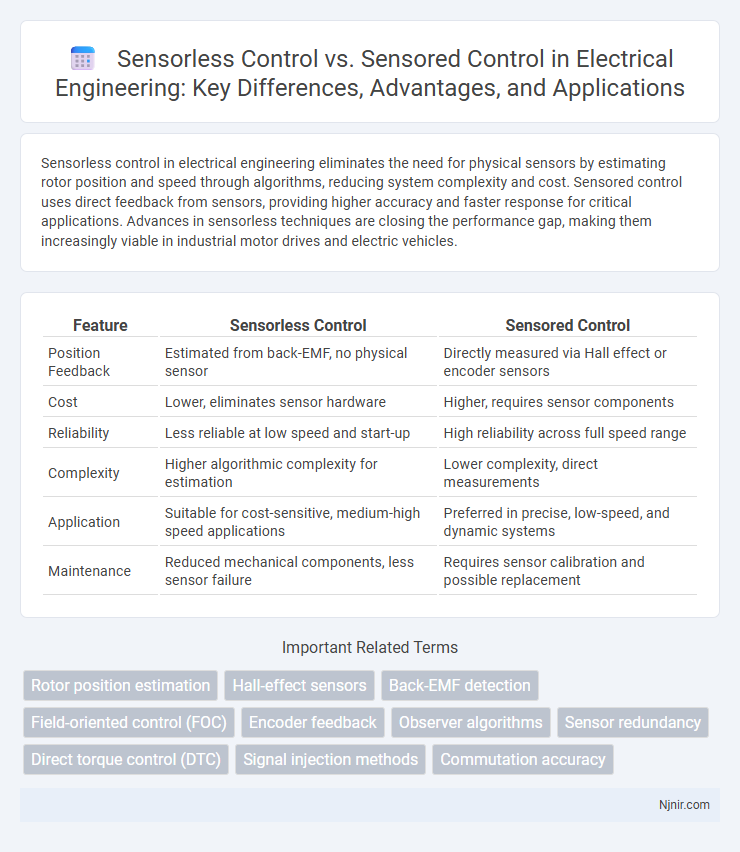

Sensorless control in electrical engineering eliminates the need for physical sensors by estimating rotor position and speed through algorithms, reducing system complexity and cost. Sensored control uses direct feedback from sensors, providing higher accuracy and faster response for critical applications. Advances in sensorless techniques are closing the performance gap, making them increasingly viable in industrial motor drives and electric vehicles.

Table of Comparison

| Feature | Sensorless Control | Sensored Control |

|---|---|---|

| Position Feedback | Estimated from back-EMF, no physical sensor | Directly measured via Hall effect or encoder sensors |

| Cost | Lower, eliminates sensor hardware | Higher, requires sensor components |

| Reliability | Less reliable at low speed and start-up | High reliability across full speed range |

| Complexity | Higher algorithmic complexity for estimation | Lower complexity, direct measurements |

| Application | Suitable for cost-sensitive, medium-high speed applications | Preferred in precise, low-speed, and dynamic systems |

| Maintenance | Reduced mechanical components, less sensor failure | Requires sensor calibration and possible replacement |

Introduction to Motor Control

Sensorless control relies on mathematical models and back-EMF estimation to manage motor speed and position without physical sensors, enhancing reliability and reducing cost. Sensored control uses physical sensors such as Hall effect sensors or encoders to provide precise rotor position feedback, enabling more accurate and responsive motor operation. In motor control, the choice between sensorless and sensored methods depends on application requirements for precision, cost, and environmental conditions.

Overview of Sensored Control

Sensored control utilizes feedback from physical sensors, such as Hall effect sensors or encoders, to precisely monitor rotor position and speed in electric motors. This method enhances accuracy and response time, enabling smoother torque control and improved performance in applications requiring high precision. Sensored control is essential in low-speed operations where accurate rotor position information is critical for efficiency and stability.

Fundamentals of Sensorless Control

Sensorless control relies on mathematical models and real-time estimation algorithms to infer rotor position and speed without physical sensors, reducing hardware costs and increasing system robustness. Techniques such as back-EMF (electromotive force) estimation, model reference adaptive systems (MRAS), and sliding mode observers form the core of sensorless control fundamentals. These methods analyze electrical signals and motor parameters, enabling precise control in applications where sensor installation is impractical or environments are harsh.

Key Differences Between Sensorless and Sensored Systems

Sensorless control relies on algorithms to estimate rotor position using back-EMF signals, eliminating the need for physical sensors and reducing hardware complexity and cost. Sensored control uses physical sensors like Hall-effect or encoders to provide accurate rotor position feedback, enabling precise low-speed operation and better dynamic response. Sensorless systems excel in cost-sensitive and robust environments, while sensored systems offer superior accuracy and reliability in applications requiring exact speed and position control.

Advantages of Sensored Motor Control

Sensored motor control offers precise rotor position feedback through Hall effect sensors or encoders, enabling accurate commutation and smoother torque delivery. This results in improved startup performance, better low-speed torque control, and enhanced system reliability in applications requiring high precision. Sensored control also facilitates fault detection and adaptive compensation, boosting overall motor efficiency and lifespan.

Benefits of Sensorless Motor Control

Sensorless motor control eliminates the need for physical sensors by estimating rotor position through algorithms, reducing hardware costs and improving system reliability. It enhances motor robustness in harsh environments by minimizing sensor-related failures and maintenance requirements. This control method also increases system compactness and simplifies installation, making it ideal for applications demanding cost-effective and durable solutions.

Application-Specific Considerations

Sensorless control is ideal for applications demanding reduced hardware costs and enhanced reliability, such as HVAC systems and small electric vehicles, where the absence of physical sensors minimizes maintenance and increases durability. Sensored control suits precision-critical applications like industrial robotics and electric automotive traction systems, offering accurate rotor position feedback essential for high-torque performance and dynamic response. Selecting between sensorless and sensored control depends on factors like required control accuracy, environmental conditions, cost constraints, and system complexity inherent to the specific application.

Performance Comparison: Efficiency and Reliability

Sensorless control systems typically offer higher efficiency by eliminating the need for physical sensors, reducing energy consumption and maintenance costs. Sensored control provides superior reliability in dynamic and low-speed operations due to precise rotor position feedback, enhancing stability and response accuracy. Efficiency in sensorless control can decrease under complex load conditions, whereas sensored control maintains consistent performance across various operational environments.

Challenges and Limitations of Each Method

Sensorless control faces challenges in accurately estimating rotor position at low speeds and during startup due to weak back-EMF signals, leading to potential instability and reduced performance. Sensored control, while offering precise feedback for better dynamic response, is limited by the added cost, complexity, and vulnerability of physical sensors to harsh environmental conditions. Both methods encounter trade-offs between reliability, cost, and control accuracy, necessitating careful selection based on application requirements.

Future Trends in Motor Control Technologies

Future trends in motor control technologies emphasize advanced sensorless control methods leveraging AI and machine learning algorithms for enhanced precision and reliability without the need for physical sensors. Sensored control systems continue to evolve by integrating smart sensors with IoT connectivity, enabling real-time monitoring and predictive maintenance. Hybrid approaches combining sensorless estimation with minimal sensor feedback are gaining traction to optimize performance and reduce system costs in electric and industrial motor applications.

Rotor position estimation

Sensorless control estimates rotor position using back-EMF or model-based algorithms, while sensored control relies on physical sensors like encoders or Hall-effect devices for direct rotor position feedback.

Hall-effect sensors

Hall-effect sensor-based sensored control provides precise rotor position feedback for accurate motor commutation, while sensorless control estimates rotor position mathematically, often sacrificing startup performance and low-speed accuracy.

Back-EMF detection

Sensorless control using Back-EMF detection eliminates the need for physical sensors by estimating rotor position through voltage feedback, enhancing system reliability and reducing hardware complexity compared to sensored control.

Field-oriented control (FOC)

Sensorless FOC optimizes efficiency and reduces costs by eliminating mechanical sensors, while sensored FOC enhances precision and reliability through real-time rotor position feedback.

Encoder feedback

Sensorless control relies on indirect estimation methods to operate without encoder feedback, whereas sensored control uses precise encoder feedback to enhance motor position and speed accuracy.

Observer algorithms

Observer algorithms in sensorless control estimate rotor position and speed by processing motor voltage and current signals, eliminating the need for physical sensors used in sensored control systems to enhance reliability and reduce costs.

Sensor redundancy

Sensorless control enhances system reliability by eliminating sensor redundancy requirements found in sensored control systems.

Direct torque control (DTC)

Sensorless control in Direct Torque Control (DTC) optimizes motor performance by estimating rotor position and torque without physical sensors, enhancing reliability and reducing costs compared to sensored control which relies on encoder or resolver feedback for precise torque and speed regulation.

Signal injection methods

Signal injection methods in sensorless control enhance rotor position estimation accuracy by detecting variations in motor impedance, offering cost-effective and maintenance-free alternatives to sensored control systems that rely on physical position sensors.

Commutation accuracy

Sensorless control offers reduced hardware cost but typically exhibits lower commutation accuracy compared to sensored control, which provides precise rotor position feedback enabling superior commutation timing for enhanced motor performance.

sensorless control vs sensored control Infographic

njnir.com

njnir.com