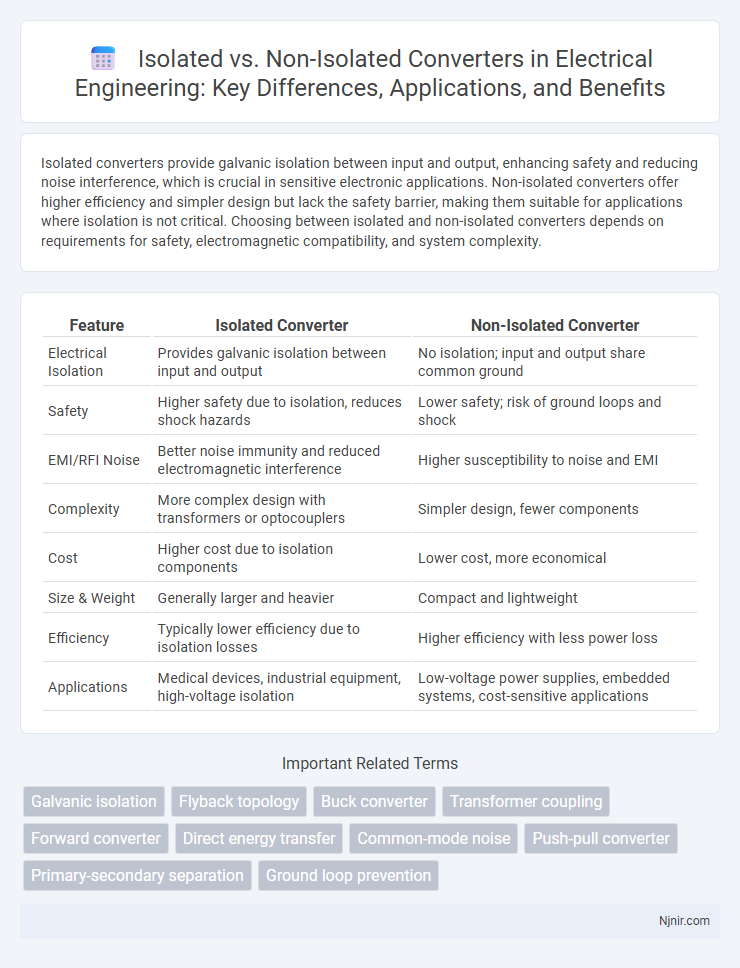

Isolated converters provide galvanic isolation between input and output, enhancing safety and reducing noise interference, which is crucial in sensitive electronic applications. Non-isolated converters offer higher efficiency and simpler design but lack the safety barrier, making them suitable for applications where isolation is not critical. Choosing between isolated and non-isolated converters depends on requirements for safety, electromagnetic compatibility, and system complexity.

Table of Comparison

| Feature | Isolated Converter | Non-Isolated Converter |

|---|---|---|

| Electrical Isolation | Provides galvanic isolation between input and output | No isolation; input and output share common ground |

| Safety | Higher safety due to isolation, reduces shock hazards | Lower safety; risk of ground loops and shock |

| EMI/RFI Noise | Better noise immunity and reduced electromagnetic interference | Higher susceptibility to noise and EMI |

| Complexity | More complex design with transformers or optocouplers | Simpler design, fewer components |

| Cost | Higher cost due to isolation components | Lower cost, more economical |

| Size & Weight | Generally larger and heavier | Compact and lightweight |

| Efficiency | Typically lower efficiency due to isolation losses | Higher efficiency with less power loss |

| Applications | Medical devices, industrial equipment, high-voltage isolation | Low-voltage power supplies, embedded systems, cost-sensitive applications |

Introduction to Power Converters in Electrical Engineering

Isolated converters utilize transformers to provide galvanic isolation between input and output, enhancing safety and noise immunity in power conversion applications. Non-isolated converters directly connect input and output circuits, offering higher efficiency and simpler design but with limited protection against electrical faults. Selecting between isolated and non-isolated converters depends on application requirements such as voltage levels, safety standards, and system complexity in electrical engineering power systems.

Defining Isolated and Non-Isolated Converters

Isolated converters feature galvanic isolation between input and output, typically using transformers to prevent direct electrical connection, enhancing safety and noise reduction. Non-isolated converters lack this separation, directly connecting input to output, resulting in simpler designs with higher efficiency but less protection against electrical faults. This distinction is critical in applications requiring strict isolation standards or compact, cost-effective solutions.

Core Operating Principles

Isolated converters use transformers to separate input and output electrically, enabling voltage level shifting and providing galvanic isolation, which enhances safety and noise immunity. Non-isolated converters directly connect input and output grounds, relying on components like inductors and capacitors for energy transfer without electrical separation. The core operating principle of isolated converters centers on magnetic coupling through transformers, whereas non-isolated converters depend on switching elements and reactive components to regulate voltage.

Key Applications and Use Cases

Isolated converters are essential in applications requiring electrical separation for safety and noise reduction, commonly found in medical devices, industrial automation, and renewable energy systems. Non-isolated converters suit cost-sensitive designs with simpler topologies, often used in point-of-load regulation for telecommunications, consumer electronics, and battery-powered devices. Both types play crucial roles depending on system isolation needs, voltage levels, and regulatory standards.

Efficiency Comparison

Isolated converters typically offer higher efficiency in applications requiring galvanic isolation, minimizing noise and ground loop issues, which enhances overall system performance. Non-isolated converters tend to have simpler designs with fewer components, resulting in lower conduction losses and higher efficiency in low-voltage, low-power scenarios. Efficiency differences largely depend on the application requirements and the specific converter topology used.

Design Complexity and Cost Factors

Isolated converters require transformers, increasing design complexity and cost due to additional components and safety considerations, while non-isolated converters have simpler designs with fewer components, making them more cost-effective for low-voltage applications. Isolation in converters provides enhanced safety and noise reduction, which adds complexity to PCB layout and thermal management. Non-isolated converters are preferred in cost-sensitive applications with less stringent isolation requirements, whereas isolated converters are essential in industrial and medical power systems demanding galvanic isolation.

Safety and Isolation Requirements

Isolated converters provide electrical separation between input and output, enhancing safety by preventing direct current paths and reducing the risk of electric shock in sensitive applications. Non-isolated converters lack this galvanic isolation, making them less suitable for systems requiring strict isolation standards but often more efficient and compact for low-voltage scenarios. Selection depends on compliance with safety regulations such as IEC 60950 or UL 60950, where isolated converters meet stringent isolation and insulation requirements critical for user and equipment protection.

Performance in Different Load Conditions

Isolated converters provide superior electrical isolation and safety, maintaining stable performance under varying load conditions due to their ability to handle transient spikes and noise more effectively. Non-isolated converters offer higher efficiency and simpler designs but may experience voltage fluctuations and reduced regulation quality during dynamic load changes. Performance in different load conditions heavily depends on isolation requirements, with isolated converters excelling in demanding environments and non-isolated types suited for steady, low-noise applications.

Selection Criteria for Engineers

Engineers select isolated converters when galvanic isolation is critical for safety, noise reduction, or compliance with regulatory standards, especially in medical, industrial, and communication applications. Non-isolated converters are preferred for higher efficiency, smaller size, and cost-sensitive designs where input and output grounds share a common reference. Key factors influencing the choice include voltage level differences, isolation voltage requirements, electromagnetic interference susceptibility, and overall system architecture.

Future Trends in Converter Technology

Isolated converters provide galvanic isolation, enhancing safety and reducing noise in applications like electric vehicles and renewable energy systems, while non-isolated converters offer compact size and higher efficiency for low-voltage, high-current scenarios. Future trends emphasize wide bandgap semiconductor materials such as SiC and GaN to improve switching speeds and thermal performance in both isolated and non-isolated designs. Integration of advanced digital control and AI-driven optimization will further enhance converter reliability, adaptability, and energy efficiency across diverse industrial and consumer applications.

Galvanic isolation

Isolated converters provide galvanic isolation to prevent direct current flow between input and output circuits, enhancing safety and noise reduction, while non-isolated converters lack this isolation, leading to potential ground loops and increased interference.

Flyback topology

Flyback converters use isolated topologies with a transformer to provide galvanic isolation and voltage scaling, while non-isolated converters rely on inductor-based designs without isolation, impacting safety and EMI performance.

Buck converter

Isolated buck converters provide galvanic isolation and enhanced safety by using transformers, while non-isolated buck converters offer simpler design, higher efficiency, and lower cost by directly stepping down voltage without isolation.

Transformer coupling

Transformer coupling in isolated converters enables electrical isolation and voltage level shifting, whereas non-isolated converters lack transformer coupling, providing direct electrical connection without isolation.

Forward converter

Forward converters are typically isolated DC-DC converters providing galvanic isolation via a transformer, unlike non-isolated converters which directly transfer energy without isolation.

Direct energy transfer

Isolated converters use transformers to provide galvanic isolation and direct energy transfer between input and output, while non-isolated converters transfer energy directly without isolation, resulting in higher efficiency but increased risk of electrical noise and safety hazards.

Common-mode noise

Isolated converters significantly reduce common-mode noise by separating input and output grounds, whereas non-isolated converters often allow common-mode noise to propagate due to shared ground paths.

Push-pull converter

The Push-pull converter is an isolated converter that uses a center-tapped transformer to provide galvanic isolation and voltage transformation, unlike non-isolated converters that directly connect input and output without isolation.

Primary-secondary separation

Isolated converters provide galvanic isolation between primary and secondary sides for enhanced safety and noise reduction, while non-isolated converters lack this separation, directly connecting input and output circuits.

Ground loop prevention

Isolated converters prevent ground loops by electrically separating input and output grounds, while non-isolated converters share a common ground, increasing the risk of ground loop interference.

Isolated converter vs Non-isolated converter Infographic

njnir.com

njnir.com