Synchronous reluctance motors offer higher efficiency and smoother operation compared to switched reluctance motors by utilizing rotor saliency without permanent magnets or windings, resulting in reduced torque ripple and acoustic noise. Switched reluctance motors, while simpler and more robust, typically experience higher torque ripple and require more complex control strategies to manage their non-linear characteristics. The choice between these motor types depends on application-specific demands for efficiency, noise levels, and control complexity.

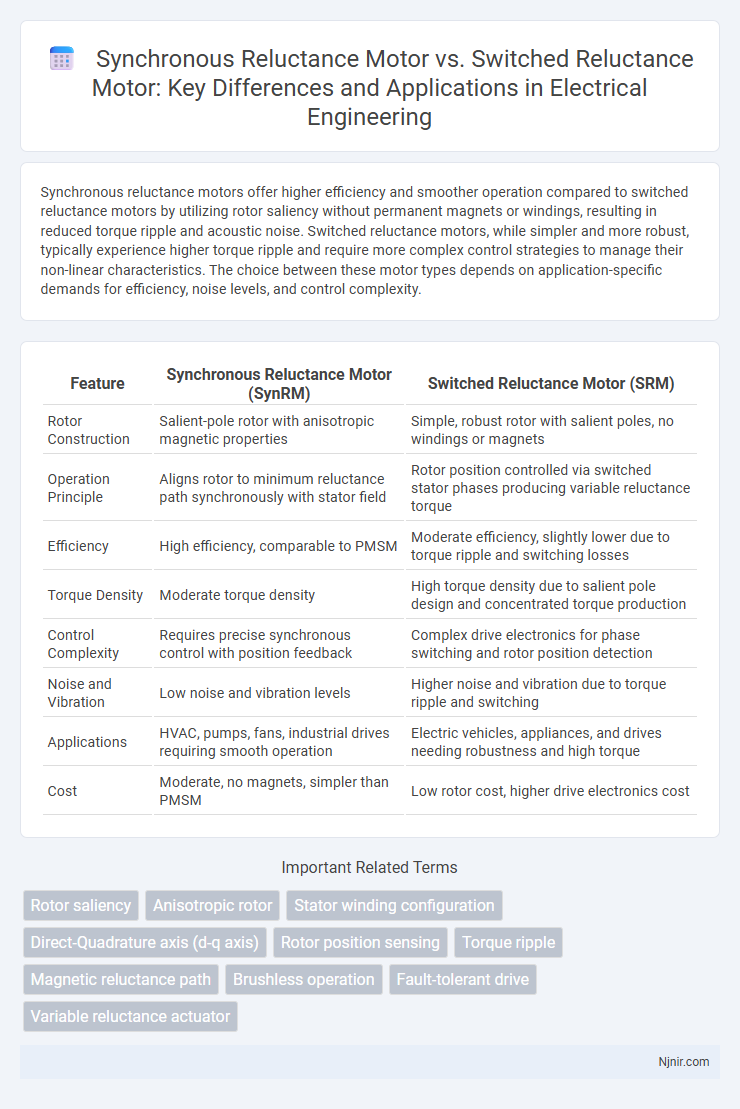

Table of Comparison

| Feature | Synchronous Reluctance Motor (SynRM) | Switched Reluctance Motor (SRM) |

|---|---|---|

| Rotor Construction | Salient-pole rotor with anisotropic magnetic properties | Simple, robust rotor with salient poles, no windings or magnets |

| Operation Principle | Aligns rotor to minimum reluctance path synchronously with stator field | Rotor position controlled via switched stator phases producing variable reluctance torque |

| Efficiency | High efficiency, comparable to PMSM | Moderate efficiency, slightly lower due to torque ripple and switching losses |

| Torque Density | Moderate torque density | High torque density due to salient pole design and concentrated torque production |

| Control Complexity | Requires precise synchronous control with position feedback | Complex drive electronics for phase switching and rotor position detection |

| Noise and Vibration | Low noise and vibration levels | Higher noise and vibration due to torque ripple and switching |

| Applications | HVAC, pumps, fans, industrial drives requiring smooth operation | Electric vehicles, appliances, and drives needing robustness and high torque |

| Cost | Moderate, no magnets, simpler than PMSM | Low rotor cost, higher drive electronics cost |

Introduction to Reluctance Motors

Reluctance motors operate on the principle of magnetic reluctance, where torque is generated by the rotor moving to a position of minimum reluctance in the magnetic circuit. Synchronous reluctance motors feature a rotor with salient poles and flux barriers to enhance magnetic anisotropy, enabling synchronous speed operation without permanent magnets. Switched reluctance motors have a simple, robust rotor with no windings or magnets and produce torque by sequentially energizing stator poles, offering high reliability and efficiency in variable-speed applications.

Working Principle: Synchronous vs Switched Reluctance Motors

Synchronous reluctance motors operate based on the alignment of the rotor's saliency with the stator's rotating magnetic field, maintaining synchronous speed without slip due to the constant magnetic flux linkage. Switched reluctance motors function by sequentially energizing stator windings to create a rotating magnetic field that pulls the rotor poles into alignment, producing torque through reluctance minimization in discrete steps. The key difference lies in the synchronous operation with steady flux in synchronous reluctance motors versus the stepped, non-synchronous torque production in switched reluctance motors.

Construction Differences and Design Features

Synchronous reluctance motors feature a rotor with flux barriers designed to create saliency and produce torque through magnetic anisotropy, while switched reluctance motors possess a salient pole rotor without windings or permanent magnets, relying on variable reluctance for operation. The synchronous reluctance motor's rotor typically includes laminated steel with precisely shaped flux paths to minimize losses, whereas the switched reluctance motor's rotor is robust with simpler geometry optimized for rapid magnetization changes. These fundamental construction differences affect their design features, with synchronous reluctance motors emphasizing smooth torque and low noise, and switched reluctance motors focusing on high torque density and ease of control.

Operating Characteristics and Performance

Synchronous reluctance motors exhibit smooth torque output with low torque ripple and higher efficiency due to their rotor design featuring anisotropic magnetic properties, making them suitable for constant-speed applications. Switched reluctance motors operate with a simple rotor lacking windings or magnets, producing high starting torque and robustness at the expense of increased torque ripple and acoustic noise. Performance-wise, synchronous reluctance motors excel in energy efficiency and vibration reduction, while switched reluctance motors offer greater fault tolerance and ease of control in harsh environments.

Advantages of Synchronous Reluctance Motors

Synchronous reluctance motors offer higher efficiency and lower acoustic noise compared to switched reluctance motors due to their rotor design, which minimizes magnetic losses and torque ripple. They provide smoother torque output and better control performance, enhancing their suitability for precision applications in HVAC systems and industrial drives. The absence of brushes and permanent magnets results in reduced maintenance and lower operational costs, making synchronous reluctance motors a reliable and cost-effective solution for energy-efficient motor applications.

Benefits of Switched Reluctance Motors

Switched reluctance motors offer high reliability due to their simple and robust rotor construction without permanent magnets or windings, reducing maintenance costs. They provide excellent efficiency across a wide speed range and high fault tolerance, making them ideal for harsh environments. Their capability for precise torque control and rapid dynamic response enhances performance in applications requiring variable speed and load conditions.

Control Techniques and Drive Requirements

Synchronous reluctance motors require precise rotor position sensing and field-oriented control algorithms to achieve efficient torque production and smooth operation, often necessitating high-performance inverters with pulse-width modulation (PWM) capabilities. Switched reluctance motors demand robust rotor position estimation methods, such as sensorless techniques or Hall-effect sensors, along with simple yet high-torque drive circuits capable of handling rapid phase switching and significant current ripple. Both motor types benefit from advanced digital signal processors (DSPs) or microcontrollers to implement real-time control strategies that balance efficiency, noise reduction, and dynamic response.

Efficiency and Power Factor Comparison

Synchronous reluctance motors typically exhibit higher efficiency due to reduced rotor losses and smoother torque production compared to switched reluctance motors, which experience higher iron and copper losses due to their doubly salient design. The power factor of synchronous reluctance motors is generally better, often close to unity under optimal load conditions, while switched reluctance motors usually operate at lower power factors because of their variable reluctance operation and non-sinusoidal phase currents. These differences make synchronous reluctance motors more suitable for applications prioritizing energy efficiency and power quality.

Applications in Industry and Emerging Fields

Synchronous reluctance motors are widely utilized in HVAC systems, pumps, and industrial compressors due to their high efficiency and smooth torque output, making them ideal for applications requiring precise speed control and low maintenance. Switched reluctance motors find growing adoption in electric vehicles, robotics, and aerospace industries, benefiting from their robust construction, high-speed capability, and fault-tolerant operation in harsh environments. Emerging fields such as renewable energy and automated manufacturing are increasingly leveraging synchronous reluctance motors for energy-efficient drives and switched reluctance motors for reliable, high-performance actuation systems.

Cost, Maintenance, and Future Trends

Synchronous reluctance motors (SynRMs) typically have higher manufacturing costs due to more complex rotor designs but offer lower maintenance expenses because they lack brushes and permanent magnets, reducing wear parts. Switched reluctance motors (SRMs) are generally cost-effective to produce with simpler construction but require more robust control systems and can experience higher maintenance from rotor noise and vibration. Future trends emphasize improving SRM noise reduction and control algorithms, while SynRM advancements focus on enhanced magnetic materials and efficiency gains for broader industrial adoption.

Rotor saliency

Synchronous reluctance motors feature a rotor with anisotropic magnetic saliency for smooth torque production, while switched reluctance motors have a salient pole rotor designed for high torque ripple and simple construction.

Anisotropic rotor

Synchronous reluctance motors feature an anisotropic rotor with distinct magnetic saliency that enables smooth torque production, while switched reluctance motors rely on a simpler, salient-pole rotor with variable inductance for torque generation.

Stator winding configuration

Synchronous reluctance motors feature distributed, sinusoidally wound stator windings optimized for smooth torque and reduced harmonics, while switched reluctance motors utilize concentrated, singly-excited stator windings designed for simple structure and robust performance.

Direct-Quadrature axis (d-q axis)

Synchronous reluctance motors exhibit smooth torque production with continuous flux in the direct-quadrature (d-q) axis, while switched reluctance motors generate torque through discrete phase switching resulting in pulsating flux on the d-q axis.

Rotor position sensing

Synchronous reluctance motors require precise rotor position sensing through encoders or resolvers for efficient control, while switched reluctance motors often use sensorless control techniques relying on inductance variation to estimate rotor position.

Torque ripple

Synchronous reluctance motors exhibit lower torque ripple compared to switched reluctance motors due to their smoother rotor design and continuous torque production.

Magnetic reluctance path

Switched reluctance motors feature a segmented rotor with distinct reluctance paths that rapidly change magnetic flux alignment, whereas synchronous reluctance motors have a continuous rotor with flux barriers shaping a smooth, low-reluctance path for efficient magnetic flux flow.

Brushless operation

Synchronous reluctance motors offer smooth brushless operation with low torque ripple and higher efficiency, while switched reluctance motors provide robust brushless operation but typically exhibit higher torque ripple and acoustic noise.

Fault-tolerant drive

Switched reluctance motors offer superior fault-tolerant drive capabilities compared to synchronous reluctance motors due to their robust rotor structure and independent phase excitation allowing continued operation despite phase faults.

Variable reluctance actuator

Switched reluctance motors offer superior torque density and variable reluctance actuation compared to synchronous reluctance motors, making them more efficient for precise variable reluctance actuator applications.

synchronous reluctance motor vs switched reluctance motor Infographic

njnir.com

njnir.com