Brushless DC (BLDC) motors offer higher efficiency and longer lifespan compared to brushed DC motors due to the absence of brushes, which reduces friction and wear. BLDC motors provide better speed control, quieter operation, and require less maintenance, making them ideal for precision applications. In contrast, brushed DC motors are simpler and less expensive but suffer from reduced durability and efficiency due to brush and commutator wear.

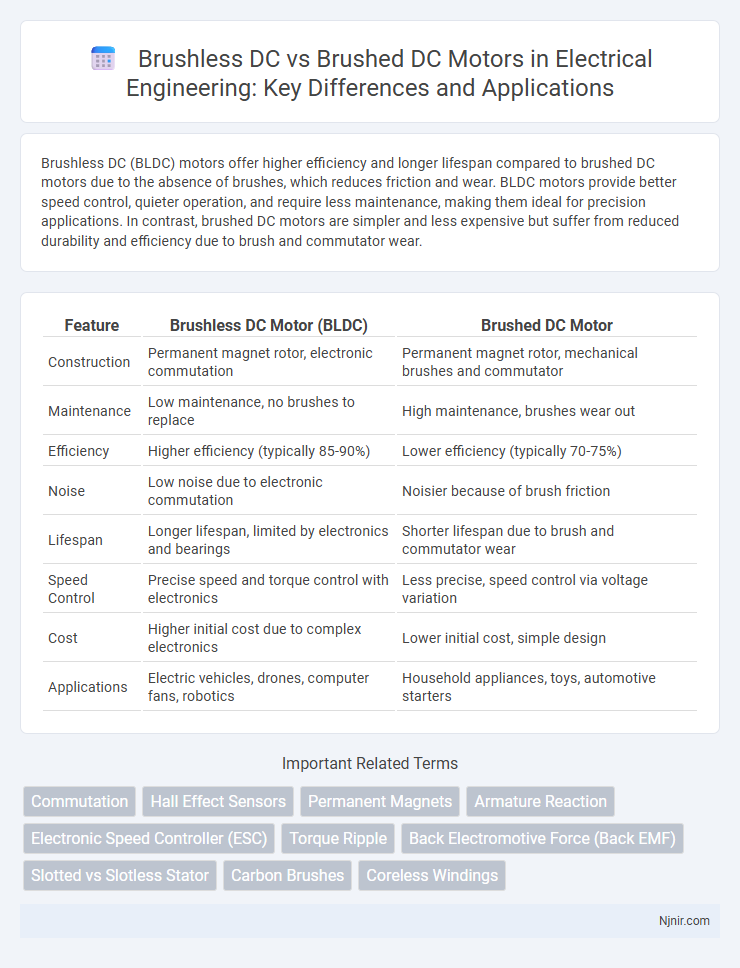

Table of Comparison

| Feature | Brushless DC Motor (BLDC) | Brushed DC Motor |

|---|---|---|

| Construction | Permanent magnet rotor, electronic commutation | Permanent magnet rotor, mechanical brushes and commutator |

| Maintenance | Low maintenance, no brushes to replace | High maintenance, brushes wear out |

| Efficiency | Higher efficiency (typically 85-90%) | Lower efficiency (typically 70-75%) |

| Noise | Low noise due to electronic commutation | Noisier because of brush friction |

| Lifespan | Longer lifespan, limited by electronics and bearings | Shorter lifespan due to brush and commutator wear |

| Speed Control | Precise speed and torque control with electronics | Less precise, speed control via voltage variation |

| Cost | Higher initial cost due to complex electronics | Lower initial cost, simple design |

| Applications | Electric vehicles, drones, computer fans, robotics | Household appliances, toys, automotive starters |

Introduction to DC Motors

DC motors convert direct current electrical energy into mechanical motion, with brushed and brushless types being the primary categories. Brushed DC motors use carbon brushes to maintain electrical contact with the rotor, resulting in simpler design but higher wear and maintenance. Brushless DC motors employ electronic commutation, providing higher efficiency, longer lifespan, and reduced noise, making them ideal for precision applications.

Fundamental Differences: Brushed vs Brushless DC Motors

Brushed DC motors use carbon brushes and a commutator to deliver current to the rotating armature, causing mechanical wear and maintenance issues, while brushless DC motors rely on electronically controlled switching with no physical brushes, resulting in higher efficiency and longer lifespan. Brushed motors generate more noise and electromagnetic interference due to the brush contact, whereas brushless motors operate smoothly with less vibration and reduced electrical noise. The fundamental difference lies in the commutation method: mechanical for brushed motors and electronic for brushless motors, which impacts durability, control precision, and application suitability.

Construction and Working Principles

Brushless DC motors eliminate brushes and commutators by using electronic controllers to switch current, resulting in reduced wear and higher efficiency. Their rotor contains permanent magnets, while the stator comprises wound coils energized electronically to create a rotating magnetic field. In contrast, brushed DC motors employ mechanical brushes and a commutator to supply current directly to the armature windings, causing friction and wear but offering simpler construction.

Efficiency and Performance Comparison

Brushless DC motors offer higher efficiency than brushed DC motors due to their electronic commutation, which reduces energy loss from friction and voltage drops across brushes. Performance-wise, brushless DC motors provide greater torque density, longer lifespan, and lower maintenance requirements, making them ideal for high-precision applications. Brushed DC motors, while simpler and cost-effective, suffer from reduced efficiency and wear over time due to brush and commutator degradation.

Maintenance Requirements and Longevity

Brushless DC motors require significantly less maintenance than brushed DC motors because they lack brushes that wear out and need replacement, reducing downtime and servicing costs. The absence of brushes in brushless motors also contributes to longer operational life, often exceeding 20,000 hours compared to the typical 5,000-10,000 hours lifespan of brushed motors. Industrial applications increasingly favor brushless DC motors for their enhanced durability, reliability, and lower total cost of ownership in demanding environments.

Speed and Torque Control Capabilities

Brushless DC (BLDC) motors offer superior speed and torque control compared to brushed DC motors due to their electronic commutation, which enables precise regulation of motor phases for consistent performance. The sensor feedback systems in BLDC motors facilitate accurate speed control and efficient torque delivery, minimizing commutation losses and wear associated with brushes. Brushed DC motors provide simpler control mechanisms but suffer from reduced efficiency and less precise torque management, especially at varying speeds and loads.

Noise Levels and Operational Smoothness

Brushless DC motors generate significantly lower noise levels compared to brushed DC motors due to the absence of brushes, which eliminates mechanical friction and sparking. Operational smoothness in brushless DC motors is enhanced by electronic commutation that ensures precise rotor control, resulting in reduced vibration and consistent torque. Brushed DC motors exhibit increased noise and less smooth operation because of brush contact and wear, causing irregular commutation and higher mechanical resistance.

Applications in Electrical Engineering

Brushless DC (BLDC) motors dominate applications requiring high efficiency, precise control, and longevity, such as robotics, aerospace actuators, and electric vehicles, due to their reduced maintenance and superior thermal management. Brushed DC motors remain prevalent in cost-sensitive, low-power applications like household appliances and toys where simplicity and lower initial cost are critical. In electrical engineering design, selecting between BLDC and brushed DC hinges on performance requirements, operational environment, and lifecycle expectations.

Cost and Complexity Considerations

Brushless DC motors typically have higher initial costs due to complex electronic controllers and sensors, while brushed DC motors are less expensive with simpler mechanical commutation. The reduced maintenance needs and longer lifespan of brushless motors often justify the upfront investment despite their complexity. In applications demanding durability and efficiency, brushless designs offer cost advantages over time despite higher initial expenses.

Future Trends in DC Motor Technology

Brushless DC motors are rapidly advancing with innovations in sensorless control techniques and high-efficiency rare-earth magnets, promising enhanced durability and reduced maintenance over traditional brushed DC motors. Emerging trends include the integration of smart IoT-enabled diagnostics and AI-optimized motor control algorithms, enabling predictive maintenance and improved energy efficiency. The shift towards brushless designs is driven by increasing demand in electric vehicles, robotics, and renewable energy systems, positioning BLDC motors as the cornerstone of next-generation DC motor technology.

Commutation

Brushless DC motors use electronic commutation for precise control and higher efficiency, while Brushed DC motors rely on mechanical commutation via brushes and a commutator, causing more wear and maintenance.

Hall Effect Sensors

Brushless DC motors rely on Hall Effect sensors for precise rotor position detection and efficient commutation, whereas brushed DC motors do not use Hall Effect sensors and rely on mechanical brushes for commutation.

Permanent Magnets

Brushless DC motors utilize permanent magnets on the rotor for higher efficiency and reduced maintenance compared to brushed DC motors, which place permanent magnets on the stator and rely on mechanical brushes for commutation.

Armature Reaction

Brushless DC motors eliminate armature reaction due to the absence of brushes and commutators, resulting in improved efficiency and reduced maintenance compared to brushed DC motors.

Electronic Speed Controller (ESC)

Brushless DC motors require specialized Electronic Speed Controllers (ESCs) that use sensorless or sensor-based commutation algorithms for precise rotor position detection, offering higher efficiency and better speed control compared to the simpler ESCs used in Brushed DC motors.

Torque Ripple

Brushless DC motors exhibit significantly lower torque ripple compared to brushed DC motors, resulting in smoother operation, higher efficiency, and reduced mechanical wear.

Back Electromotive Force (Back EMF)

Brushless DC motors generate a more consistent and higher Back Electromotive Force (Back EMF) compared to Brushed DC motors, resulting in improved efficiency and precise speed control.

Slotted vs Slotless Stator

Slotted stators in brushed DC motors provide precise torque control with mechanical commutation, while slotless stators in brushless DC motors enable higher efficiency and reduced cogging torque due to electronic commutation and smoother magnetic flux distribution.

Carbon Brushes

Brushless DC motors eliminate carbon brushes, reducing maintenance and wear compared to brushed DC motors, which rely on carbon brushes for electrical contact and experience friction-related degradation.

Coreless Windings

Brushless DC motors with coreless windings offer higher efficiency, reduced cogging torque, and improved thermal performance compared to brushed DC motors with traditional iron-core windings.

Brushless DC vs Brushed DC Infographic

njnir.com

njnir.com