Power Factor Correction (PFC) enhances the efficiency of electrical systems by minimizing reactive power and improving the power factor, reducing energy losses in distribution networks. Uninterruptible Power Supplies (UPS) provide backup power during outages, ensuring continuous operation of critical devices by switching to battery power instantly. While PFC optimizes power quality and reduces utility costs, UPS guarantees reliability and protection against power disruptions.

Table of Comparison

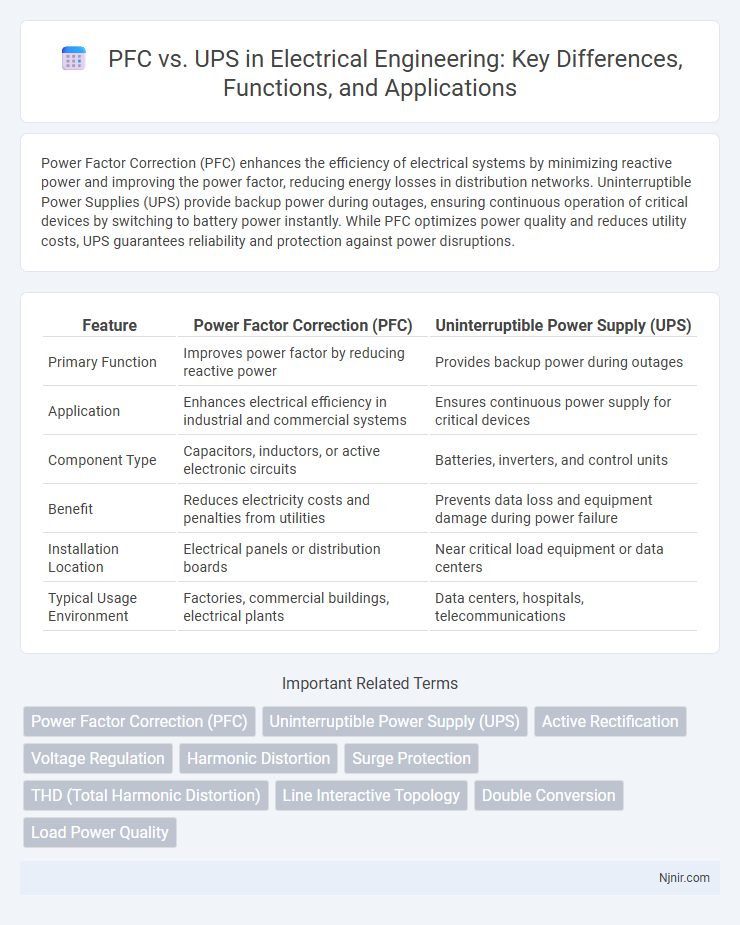

| Feature | Power Factor Correction (PFC) | Uninterruptible Power Supply (UPS) |

|---|---|---|

| Primary Function | Improves power factor by reducing reactive power | Provides backup power during outages |

| Application | Enhances electrical efficiency in industrial and commercial systems | Ensures continuous power supply for critical devices |

| Component Type | Capacitors, inductors, or active electronic circuits | Batteries, inverters, and control units |

| Benefit | Reduces electricity costs and penalties from utilities | Prevents data loss and equipment damage during power failure |

| Installation Location | Electrical panels or distribution boards | Near critical load equipment or data centers |

| Typical Usage Environment | Factories, commercial buildings, electrical plants | Data centers, hospitals, telecommunications |

Introduction to PFC and UPS in Electrical Engineering

Power Factor Correction (PFC) improves the efficiency and stability of electrical systems by minimizing reactive power and optimizing voltage and current waveforms in AC circuits. Uninterruptible Power Supply (UPS) systems provide reliable backup power during outages, ensuring continuous operation of critical equipment by supplying instantaneous power from batteries or other energy storage devices. Both PFC and UPS are essential components in electrical engineering for enhancing power quality and reliability in industrial and commercial applications.

Understanding Power Factor Correction (PFC)

Power Factor Correction (PFC) enhances electrical system efficiency by reducing reactive power and improving the power factor toward unity, which minimizes energy loss and lowers electricity bills. Unlike Uninterruptible Power Supplies (UPS) that provide backup power during outages, PFC devices primarily optimize power quality and reduce harmonics without supplying emergency power. Implementing PFC in industrial or commercial settings reduces strain on the electrical grid and extends equipment lifespan by ensuring stable voltage and current flows.

Overview of Uninterruptible Power Supply (UPS) Systems

Uninterruptible Power Supply (UPS) systems provide immediate backup power during outages, ensuring continuous operation of critical electronic devices. These systems integrate batteries and power conditioning components to maintain voltage stability and protect against power surges and fluctuations. UPS technology includes various types such as offline, line-interactive, and online double-conversion, each offering different levels of power quality and response time.

PFC: Types and Applications

Power Factor Correction (PFC) enhances energy efficiency by minimizing reactive power in electrical systems, with two main types: passive PFC utilizing inductors and capacitors, and active PFC employing power electronics for dynamic correction. Passive PFC is cost-effective and suitable for simple, low-power applications, while active PFC provides higher power factor ratings and reduces harmonic distortion, making it ideal for complex, high-power systems like uninterruptible power supplies (UPS). In UPS applications, active PFC ensures stable voltage and improved system reliability, supporting sensitive electronics by maintaining consistent power quality and reducing energy costs.

UPS: Classifications and Use Cases

Uninterruptible Power Supplies (UPS) are classified into three main types: standby, line-interactive, and double-conversion online, each tailored for specific protection levels and application needs. Standby UPS systems provide basic battery backup for personal computers, while line-interactive models regulate voltage fluctuations suitable for small data centers and networking equipment. Double-conversion online UPS units offer the highest protection with continuous power conditioning, ideal for critical servers, medical equipment, and industrial processes requiring uninterrupted power supply and minimal transfer time.

Key Differences Between PFC and UPS

Power Factor Correction (PFC) improves the efficiency of electrical power usage by reducing reactive power in devices, while an Uninterruptible Power Supply (UPS) provides emergency power backup during outages. PFC primarily optimizes energy consumption and minimizes electricity costs by correcting power factor, whereas UPS ensures continuous power delivery to critical equipment, preventing data loss and hardware damage. The key distinction lies in PFC's role in power quality enhancement versus UPS's function in power continuity and protection.

Impact of PFC and UPS on Power Quality

Power Factor Correction (PFC) significantly improves power quality by reducing total harmonic distortion (THD) and enhancing voltage stability, which minimizes energy losses and prevents equipment overheating. Uninterruptible Power Supply (UPS) systems maintain consistent power delivery during outages or voltage sags, protecting sensitive electronics from outages, surges, and transients that degrade power quality. Together, PFC and UPS technologies optimize electrical system reliability by stabilizing voltage levels and reducing harmonic interference, ensuring efficient energy use and extended equipment lifespan.

Efficiency Considerations: PFC vs UPS

Power Factor Correction (PFC) improves electrical efficiency by reducing reactive power and minimizing energy losses in AC systems, enhancing overall power quality. Uninterruptible Power Supplies (UPS) ensure continuous power delivery and protect sensitive equipment but can introduce conversion losses that reduce system efficiency. Comparing PFC and UPS, PFC optimizes power factor and reduces utility charges, while UPS prioritizes reliability and power continuity, often with a trade-off in energy efficiency due to battery and inverter operation.

PFC and UPS in Industrial and Commercial Settings

Power Factor Correction (PFC) enhances energy efficiency in industrial and commercial settings by reducing reactive power, lowering electricity costs, and improving the lifespan of electrical equipment. Uninterruptible Power Supplies (UPS) ensure continuous power availability during outages, protecting sensitive machinery and maintaining operational continuity. Combining PFC with UPS systems optimizes power quality and reliability, critical for minimizing downtime and improving overall productivity in demanding environments.

Choosing Between PFC and UPS for Optimal Power Management

Choosing between Power Factor Correction (PFC) and Uninterruptible Power Supply (UPS) depends on specific power management needs: PFC improves energy efficiency by reducing reactive power and lowering electricity costs, while UPS provides backup power and protects equipment from outages and voltage spikes. For environments with frequent power disturbances, UPS systems ensure continuous operation and data integrity, whereas PFC is ideal for optimizing power quality and reducing demand charges in stable electrical setups. Evaluating load requirements, power quality issues, and criticality of uninterrupted power helps determine whether PFC, UPS, or a combination of both offers optimal power management.

Power Factor Correction (PFC)

Power Factor Correction (PFC) enhances electrical efficiency by reducing reactive power and improving voltage stability, whereas Uninterruptible Power Supplies (UPS) primarily provide backup power during outages without directly addressing power factor issues.

Uninterruptible Power Supply (UPS)

Uninterruptible Power Supply (UPS) systems provide reliable, continuous power during outages, protecting sensitive electronics from data loss and hardware damage.

Active Rectification

Active rectification in PFC circuits enhances power factor by using controlled semiconductor switches to reduce harmonic distortion compared to traditional UPS rectifiers.

Voltage Regulation

PFC circuits enhance voltage regulation by reducing harmonic distortion and improving power factor, while UPS systems maintain stable voltage output during power interruptions through battery backup and voltage conditioning.

Harmonic Distortion

PFC (Power Factor Correction) reduces harmonic distortion by improving power quality and minimizing current waveform distortion, while UPS (Uninterruptible Power Supply) systems often introduce harmonic distortion due to inverter operation unless equipped with advanced filters.

Surge Protection

PFC reduces electrical noise and harmonic distortion, while UPS systems provide critical surge protection by regulating voltage spikes and ensuring continuous power supply.

THD (Total Harmonic Distortion)

PFC (Power Factor Correction) improves power quality by reducing THD (Total Harmonic Distortion) in AC circuits, whereas UPS (Uninterruptible Power Supply) systems primarily provide backup power with varying THD levels depending on inverter design.

Line Interactive Topology

Line Interactive UPS topologies integrate Power Factor Correction (PFC) to enhance energy efficiency and voltage regulation, reducing harmonic distortion and improving overall power quality compared to standard UPS systems.

Double Conversion

Double conversion UPS systems provide continuous power by isolating equipment from raw power through simultaneous rectification and inversion, delivering consistently clean voltage and frequency for critical loads compared to PFC-based power supplies that primarily improve input power efficiency.

Load Power Quality

Power Factor Correction (PFC) improves load power quality by reducing harmonic distortion and reactive power, whereas Uninterruptible Power Supplies (UPS) primarily ensure continuous power delivery with some models also enhancing voltage stability and minimizing power fluctuations.

PFC vs UPS Infographic

njnir.com

njnir.com