Ohmic heating uses electrical current passed through a conductive material to generate heat via its resistance, resulting in uniform and rapid temperature rise. Induction heating relies on electromagnetic fields to induce eddy currents in a conductive workpiece, producing localized and precise heating without direct contact. Ohmic heating is generally more suitable for bulk materials and liquids, while induction heating excels in heating metals with high efficiency and fast response times.

Table of Comparison

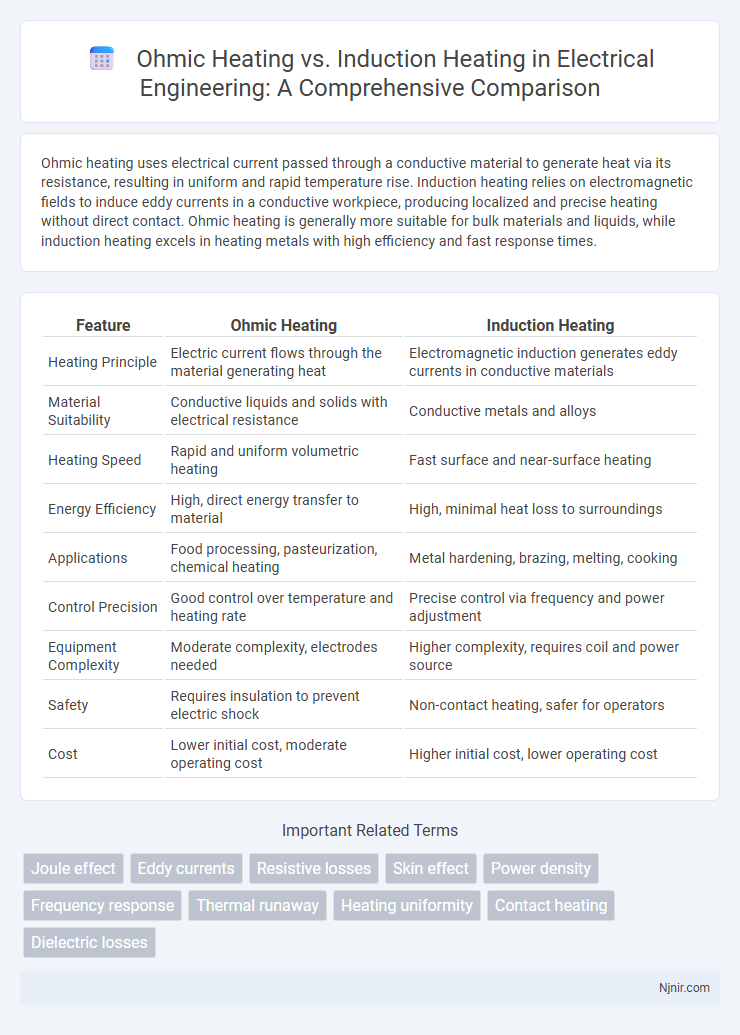

| Feature | Ohmic Heating | Induction Heating |

|---|---|---|

| Heating Principle | Electric current flows through the material generating heat | Electromagnetic induction generates eddy currents in conductive materials |

| Material Suitability | Conductive liquids and solids with electrical resistance | Conductive metals and alloys |

| Heating Speed | Rapid and uniform volumetric heating | Fast surface and near-surface heating |

| Energy Efficiency | High, direct energy transfer to material | High, minimal heat loss to surroundings |

| Applications | Food processing, pasteurization, chemical heating | Metal hardening, brazing, melting, cooking |

| Control Precision | Good control over temperature and heating rate | Precise control via frequency and power adjustment |

| Equipment Complexity | Moderate complexity, electrodes needed | Higher complexity, requires coil and power source |

| Safety | Requires insulation to prevent electric shock | Non-contact heating, safer for operators |

| Cost | Lower initial cost, moderate operating cost | Higher initial cost, lower operating cost |

Introduction to Ohmic and Induction Heating

Ohmic heating uses electrical resistance to generate heat internally by passing alternating current through food or materials, enabling rapid and uniform heating. Induction heating employs electromagnetic fields to induce eddy currents in conductive materials, causing localized heating without direct contact. Both methods offer energy-efficient and precise temperature control for industrial and food processing applications.

Fundamental Principles of Ohmic Heating

Ohmic heating operates on the principle of passing an electric current directly through a conductive material, generating heat uniformly due to the material's electrical resistance. This method ensures rapid and volumetric heating, as the heat is produced internally rather than relying on external heat transfer. Key parameters influencing ohmic heating efficiency include electrical conductivity, material composition, and applied voltage.

Core Concepts of Induction Heating

Induction heating uses electromagnetic fields to generate heat directly within conductive materials through induced eddy currents, offering rapid and precise temperature control. Unlike ohmic heating, which passes an electric current directly through the material to produce heat, induction heating relies on magnetic field interaction without direct contact. This core concept enables efficient, localized heating ideal for metals and reduces energy loss and surface contamination.

Key Differences Between Ohmic and Induction Heating

Ohmic heating utilizes direct electrical current passing through a conductive material to generate internal heat via electrical resistance, while induction heating relies on electromagnetic fields to induce eddy currents in a metallic object, producing heat. Ohmic heating is highly efficient for uniform heating in conductive fluids and solids with consistent electrical properties, whereas induction heating offers rapid, localized heating primarily suited for metals with varying shapes and surface areas. The key differences lie in their energy transfer mechanisms, application scope, and suitability for different materials based on electrical conductivity and magnetic properties.

Heat Generation Mechanisms in Electrical Engineering Applications

Ohmic heating generates heat through the direct passage of electric current, causing resistance within the conductive material, which converts electrical energy into thermal energy uniformly throughout the volume. Induction heating relies on electromagnetic induction to produce eddy currents within a conductive object, leading to localized heating primarily at the surface due to the skin effect. Both methods are critical in electrical engineering applications for efficient heat generation, with ohmic heating favored for bulk heating and induction heating optimized for surface or rapid heating processes.

Efficiency and Energy Consumption Comparison

Ohmic heating achieves high energy efficiency by directly converting electrical energy into heat within the material, resulting in rapid and uniform heating with minimal heat loss. Induction heating offers localized heating primarily on conductive materials with efficiencies typically ranging from 70% to 90%, depending on coil design and frequency. Overall, ohmic heating often surpasses induction heating in energy consumption efficiency for bulk heating processes, while induction heating excels in targeted surface heating applications.

Material Compatibility and Application Scope

Ohmic heating is highly compatible with conductive materials like saline solutions and certain metals, making it suitable for uniform heating in food processing and chemical reactions. Induction heating works best with ferromagnetic and conductive metals, providing rapid and localized heating ideal for metal forging, brazing, and surface hardening. Each method's application scope is defined by its compatibility; ohmic heating excels in liquid and semi-solid materials while induction heating targets solid metallic components.

Control, Safety, and System Design Considerations

Ohmic heating offers precise temperature control through direct electrical resistance heating, enabling uniform heating and quick response to temperature adjustments, which enhances safety by reducing overheating risks. Induction heating relies on electromagnetic fields to induce currents in conductive materials, requiring complex system designs with careful shielding and sensor integration to ensure operator safety and maintain consistent control. System design considerations for ohmic heating emphasize electrode configuration and electrolyte properties, while induction heating demands optimized coil design and material compatibility to maximize efficiency and minimize electromagnetic interference.

Industrial and Commercial Use Cases

Ohmic heating offers precise temperature control for processing viscous liquids and pastes, making it ideal for food sterilization and chemical manufacturing in industrial settings. Induction heating provides rapid, localized heating with high energy efficiency, commonly used for metal hardening, brazing, and plastic welding in commercial manufacturing. Both methods enhance production speed and product quality while reducing energy consumption compared to conventional heating techniques.

Future Trends in Electrical Heating Technologies

Ohmic heating and induction heating are evolving with advancements in energy efficiency, precision control, and eco-friendly applications. Future trends emphasize integrating IoT and AI for real-time monitoring and adaptive heating processes, enhancing performance in manufacturing and food processing industries. Innovations in material science and power electronics aim to improve scalability and reduce operational costs, positioning these technologies as key solutions in sustainable electrical heating systems.

Joule effect

Ohmic heating directly utilizes the Joule effect by converting electrical energy into heat through resistance in conductive materials, whereas induction heating generates heat indirectly by inducing eddy currents within the material.

Eddy currents

Induction heating utilizes eddy currents generated by alternating magnetic fields to rapidly heat conductive materials, whereas ohmic heating relies on direct electrical resistance without eddy current formation.

Resistive losses

Ohmic heating generates resistive losses through direct electrical resistance in the material, while induction heating minimizes resistive losses by inducing eddy currents and magnetic fields for efficient heat generation.

Skin effect

Ohmic heating generates uniform heat through electrical resistance in conductive materials, while induction heating causes the skin effect, concentrating heat near the surface due to induced eddy currents in conductive metals.

Power density

Induction heating achieves higher power density than ohmic heating by concentrating electromagnetic energy directly into conductive materials, enabling rapid and efficient temperature rise.

Frequency response

Ohmic heating operates efficiently at lower frequencies typically in the range of 50-60 Hz to generate heat through electrical resistance, while induction heating relies on high-frequency alternating currents, often between 10 kHz and 1 MHz, to produce eddy currents and magnetic hysteresis for rapid and localized heating.

Thermal runaway

Ohmic heating reduces the risk of thermal runaway through uniform electric current distribution, while induction heating may experience localized hotspots that increase thermal runaway potential.

Heating uniformity

Ohmic heating provides superior heating uniformity by directly passing electric current through the material, whereas induction heating achieves less uniformity due to surface-restricted eddy currents.

Contact heating

Ohmic heating relies on direct electrical contact with the material to generate heat through electrical resistance, whereas induction heating transfers heat without physical contact by inducing eddy currents within conductive materials.

Dielectric losses

Dielectric losses in ohmic heating arise from the direct flow of electric current through conductive materials, whereas induction heating minimizes these losses by generating eddy currents through electromagnetic fields without direct contact.

ohmic heating vs induction heating Infographic

njnir.com

njnir.com