Piezoelectric actuators deliver precise, high-frequency movements with rapid response times by converting electrical signals into mechanical displacement through crystal deformation. Electromagnetic actuators operate based on magnetic fields generated by electric currents, providing large forces and longer travel distances suitable for applications requiring higher power. Piezoelectric actuators excel in miniaturized, high-precision devices, whereas electromagnetic actuators are preferred in systems demanding robust force and stroke capabilities.

Table of Comparison

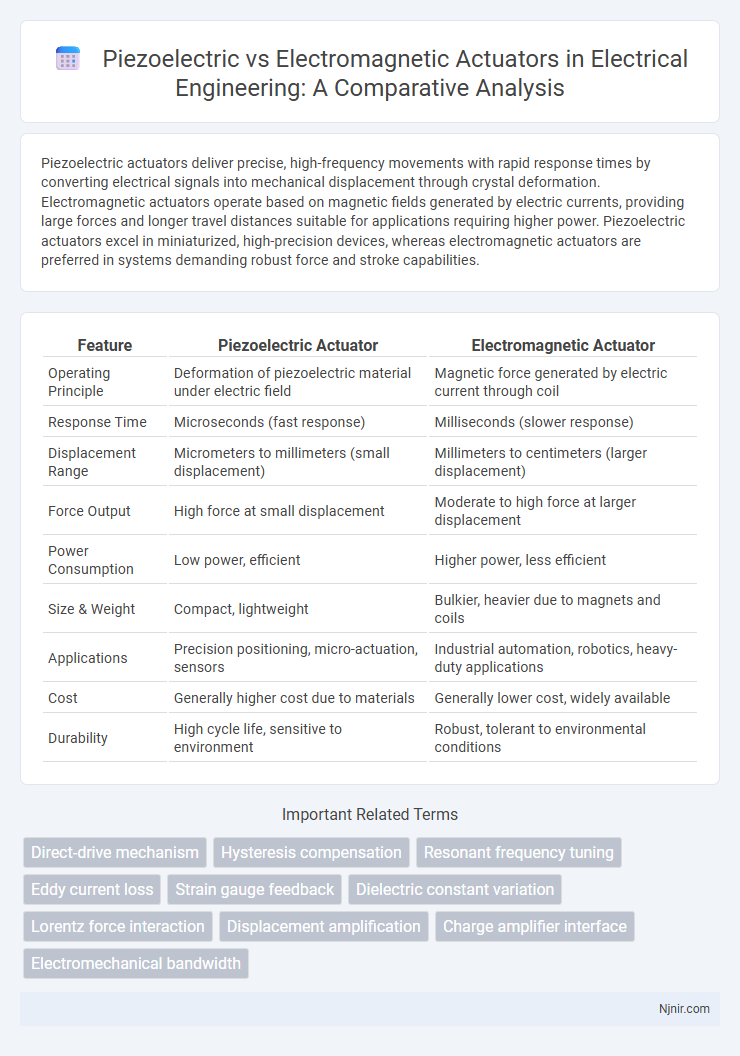

| Feature | Piezoelectric Actuator | Electromagnetic Actuator |

|---|---|---|

| Operating Principle | Deformation of piezoelectric material under electric field | Magnetic force generated by electric current through coil |

| Response Time | Microseconds (fast response) | Milliseconds (slower response) |

| Displacement Range | Micrometers to millimeters (small displacement) | Millimeters to centimeters (larger displacement) |

| Force Output | High force at small displacement | Moderate to high force at larger displacement |

| Power Consumption | Low power, efficient | Higher power, less efficient |

| Size & Weight | Compact, lightweight | Bulkier, heavier due to magnets and coils |

| Applications | Precision positioning, micro-actuation, sensors | Industrial automation, robotics, heavy-duty applications |

| Cost | Generally higher cost due to materials | Generally lower cost, widely available |

| Durability | High cycle life, sensitive to environment | Robust, tolerant to environmental conditions |

Introduction to Actuators in Electrical Engineering

Piezoelectric actuators convert electrical energy into precise mechanical displacement using the deformation of piezoelectric materials, offering high-frequency response and fine resolution ideal for micro-positioning applications. Electromagnetic actuators utilize magnetic fields generated by electric current to produce motion, delivering high force, larger strokes, and robustness suitable for industrial automation and heavy-duty tasks. In electrical engineering, selecting between piezoelectric and electromagnetic actuators depends on application requirements such as response speed, force output, displacement range, and precision.

Fundamental Working Principles

Piezoelectric actuators operate by converting electrical energy into mechanical displacement through the deformation of piezoelectric crystals under an applied voltage. Electromagnetic actuators function based on the interaction between magnetic fields and electric currents, generating mechanical force via Lorentz forces or magnetic attraction. The precise control of piezoelectric actuators relies on direct crystal strain, while electromagnetic actuators utilize coil currents and magnetic field modulation for motion.

Overview of Piezoelectric Actuators

Piezoelectric actuators utilize the converse piezoelectric effect to convert electrical energy into precise mechanical displacement, enabling ultra-fine positioning in applications such as optics and nanotechnology. These actuators excel in delivering high-resolution motion with rapid response times and minimal power consumption, outperforming electromagnetic actuators in compactness and frequency bandwidth. Common piezoelectric materials include lead zirconate titanate (PZT) and quartz, which offer exceptional durability and stability under cyclic loading conditions.

Overview of Electromagnetic Actuators

Electromagnetic actuators convert electrical energy into mechanical motion using magnetic fields generated by current-carrying coils and permanent magnets. Common types include solenoids, voice coil actuators, and rotary motors, offering a range of motion types such as linear and rotary. Their advantages include high force output, relatively simple control systems, and well-established manufacturing processes, making them ideal for applications requiring robust and efficient actuation.

Key Performance Parameters Comparison

Piezoelectric actuators offer high precision with nanometer-scale resolution and fast response times typically in the microsecond range, making them ideal for applications requiring fine positional control. Electromagnetic actuators generally provide greater force output and longer stroke lengths, often measured in millimeters to centimeters, suitable for tasks demanding higher mechanical power. Key performance parameters such as displacement range, force generation, response speed, and energy efficiency distinctly favor piezoelectric actuators for high-precision, low-force operations, whereas electromagnetic actuators excel in applications needing larger motion and higher force.

Applications in Modern Electrical Systems

Piezoelectric actuators excel in precision positioning and vibration control in modern electrical systems, commonly used in micro-electromechanical systems (MEMS), optical devices, and medical equipment due to their fast response and high resolution. Electromagnetic actuators dominate in applications requiring higher force and longer stroke, such as in electric vehicles, industrial machinery, and robotic arms, leveraging their robustness and straightforward control. Both actuator types enable advancements in automation and smart technology, with piezoelectric actuators optimizing nanoscale accuracy and electromagnetic actuators providing scalable power solutions.

Advantages and Limitations of Piezoelectric Actuators

Piezoelectric actuators offer high precision, fast response times, and compact size, making them ideal for applications requiring fine motion control and high-frequency operation. They exhibit low power consumption and no electromagnetic interference, which is advantageous in sensitive environments. However, their limited stroke length and lower force output compared to electromagnetic actuators restrict their use to small displacement tasks, while material aging and temperature sensitivity can affect long-term performance.

Advantages and Limitations of Electromagnetic Actuators

Electromagnetic actuators offer high force output and large stroke capabilities, making them ideal for heavy-duty applications and industrial automation. Their limitations include lower precision and slower response times compared to piezoelectric actuators, as well as higher power consumption and increased electromagnetic interference in sensitive environments. Despite these drawbacks, electromagnetic actuators remain cost-effective and robust for tasks requiring significant mechanical displacement and force.

Selection Criteria for Electrical Engineering Designs

Piezoelectric actuators offer high precision, fast response times, and compact size, making them ideal for applications requiring fine positional control and low power consumption. Electromagnetic actuators provide greater force output and simpler integration in systems where high power and robustness are critical, often used in industrial automation or robotics. Selection criteria focus on desired force, displacement range, speed, power availability, and environmental conditions such as temperature and electromagnetic interference tolerance.

Future Trends and Emerging Technologies

Future trends in piezoelectric actuators emphasize enhanced material composites and nanostructured films to improve precision and energy efficiency. Emerging electromagnetic actuator technologies focus on miniaturization with integrated smart sensors and advanced control algorithms for real-time adaptability. Both actuator types are increasingly incorporated into IoT and autonomous systems, driving innovations in robotics, medical devices, and aerospace applications.

Direct-drive mechanism

Direct-drive piezoelectric actuators offer higher precision and faster response than electromagnetic actuators due to their inherent nanoscale displacement capabilities and lack of gears or belts.

Hysteresis compensation

Piezoelectric actuators exhibit significant hysteresis effects requiring advanced compensation algorithms, while electromagnetic actuators typically demonstrate lower hysteresis, resulting in simpler control strategies.

Resonant frequency tuning

Piezoelectric actuators offer precise resonant frequency tuning capabilities with high sensitivity and rapid response, whereas electromagnetic actuators exhibit broader tuning ranges but lower frequency precision due to mechanical inertia.

Eddy current loss

Piezoelectric actuators exhibit significantly lower Eddy current loss compared to electromagnetic actuators due to their non-metallic, dielectric materials and absence of induced currents in conductive components.

Strain gauge feedback

Piezoelectric actuators provide higher precision and faster response with integrated strain gauge feedback, enabling real-time displacement measurement, while electromagnetic actuators rely on external sensors due to limited inherent feedback capabilities.

Dielectric constant variation

Piezoelectric actuators exhibit performance variations primarily due to changes in dielectric constant, affecting their capacitive behavior and sensitivity, unlike electromagnetic actuators that rely on magnetic fields and are less influenced by dielectric properties.

Lorentz force interaction

Lorentz force interaction in electromagnetic actuators generates motion through magnetic field and electric current, whereas piezoelectric actuators rely on mechanical strain induced by electric charge without involving Lorentz forces.

Displacement amplification

Piezoelectric actuators achieve higher displacement amplification through mechanical leverage mechanisms despite their inherently small strain, whereas electromagnetic actuators provide larger direct displacement but with lower force density.

Charge amplifier interface

Piezoelectric actuators require a charge amplifier interface to convert high-impedance charge signals into usable voltage, whereas electromagnetic actuators typically use current-driven amplifiers for direct coil excitation.

Electromechanical bandwidth

Piezoelectric actuators offer a higher electromechanical bandwidth, often exceeding tens of kilohertz, compared to electromagnetic actuators which typically operate effectively within a few hundred hertz to a few kilohertz range.

piezoelectric vs electromagnetic actuator Infographic

njnir.com

njnir.com