Plated Through-Hole (PTH) components offer robust mechanical strength and are ideal for high-stress applications requiring durable connections. Surface-Mount Devices (SMD) enable higher component density and improved electrical performance due to shorter lead lengths and reduced parasitic inductance. Choosing between PTH and SMD depends on factors like assembly complexity, board space optimization, and production cost efficiency.

Table of Comparison

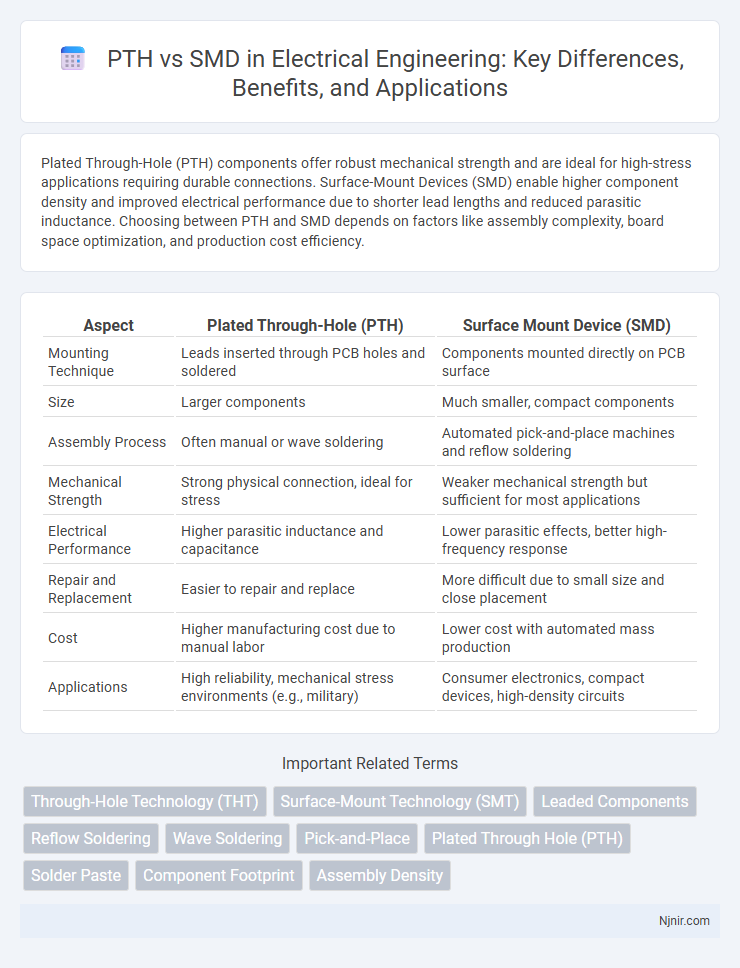

| Aspect | Plated Through-Hole (PTH) | Surface Mount Device (SMD) |

|---|---|---|

| Mounting Technique | Leads inserted through PCB holes and soldered | Components mounted directly on PCB surface |

| Size | Larger components | Much smaller, compact components |

| Assembly Process | Often manual or wave soldering | Automated pick-and-place machines and reflow soldering |

| Mechanical Strength | Strong physical connection, ideal for stress | Weaker mechanical strength but sufficient for most applications |

| Electrical Performance | Higher parasitic inductance and capacitance | Lower parasitic effects, better high-frequency response |

| Repair and Replacement | Easier to repair and replace | More difficult due to small size and close placement |

| Cost | Higher manufacturing cost due to manual labor | Lower cost with automated mass production |

| Applications | High reliability, mechanical stress environments (e.g., military) | Consumer electronics, compact devices, high-density circuits |

Introduction to PTH and SMD Technologies

Plated Through-Hole (PTH) technology involves inserting electronic component leads into drilled holes on a printed circuit board (PCB) and soldering them on the opposite side, providing strong mechanical bonds suitable for components subjected to mechanical stress. Surface Mount Device (SMD) technology mounts components directly onto the PCB surface, enabling higher component density, reduced assembly time, and improved electrical performance due to shorter lead lengths. The evolution from PTH to SMD has driven miniaturization and enhanced functionality in modern electronic devices.

Key Differences Between PTH and SMD

PTH (Plated Through-Hole) components are mounted by inserting leads through drilled holes on the PCB and soldered on the opposite side, offering strong mechanical bonds suitable for heavy or high-stress applications. SMD (Surface-Mount Device) components are directly soldered onto the PCB surface without holes, allowing for higher component density and automated assembly, leading to faster production and reduced costs. Key differences include the mounting technique, mechanical strength, assembly speed, and suitability for compact circuit designs.

Working Principles of PTH and SMD

PTH (Plated Through-Hole) components are mounted by inserting leads through drilled holes on a PCB, creating strong mechanical bonds and reliable electrical connections via soldering on both sides of the board. SMD (Surface-Mount Device) components, conversely, are placed directly onto the PCB surface pads and soldered using reflow or wave soldering techniques, allowing for higher component density and automated assembly. The primary working principle of PTH involves vertical electrical pathways through the PCB, while SMD relies on surface-level connections enhancing miniaturization and fabrication speed.

Material Requirements in PTH vs SMD

PTH (Plated Through-Hole) components require precise hole plating and thicker PCB layers to ensure reliable electrical connections, demanding more robust material specifications compared to SMD (Surface Mount Device) components. SMDs use surface pads without plated holes, allowing for thinner PCBs and less stringent material requirements, which reduces manufacturing complexity and cost. Material requirements for PTH emphasize high thermal and mechanical durability to withstand soldering through-hole processes, while SMDs prioritize surface finish quality and pad design for optimal solder adhesion.

Manufacturing Process: PTH vs SMD

Plated Through-Hole (PTH) technology involves inserting component leads into drilled holes on a PCB and soldering them to pads on both sides, providing strong mechanical bonds ideal for connectors and high-stress components. Surface Mount Device (SMD) manufacturing places components directly onto the PCB surface pads without drilling, allowing for higher component density and automated placement, which enhances production speed and reduces costs. The PTH process demands additional drilling and soldering steps, increasing complexity and time, while SMD leverages reflow soldering techniques suitable for mass production and miniaturization.

Reliability and Durability: Comparative Analysis

PTH (Plated Through-Hole) connections exhibit higher mechanical strength and durability due to their robust solder joints extending through the PCB, making them ideal for applications subjected to mechanical stress or thermal cycling. In contrast, SMD (Surface Mount Device) solder joints are more susceptible to fatigue and micro-cracking over time, especially under vibrational load, though advancements in solder materials and PCB design have improved their long-term reliability. Reliability assessments show PTH is preferred for high-reliability scenarios such as aerospace, while SMD is favored for compact, high-density electronics where moderate durability suffices.

Assembly and Repair Considerations

PTH (Plated Through-Hole) assemblies provide robust mechanical stability and are ideal for components subjected to mechanical stress, making them preferable for repair due to easier soldering and desoldering with conventional tools. SMD (Surface Mount Device) assemblies support higher component densities and automated placement but pose challenges in manual repair, often requiring specialized rework stations and precise temperature control. The choice between PTH and SMD in assembly and repair hinges on factors like component size, board complexity, and long-term maintenance requirements.

Cost Analysis: PTH Versus SMD

Cost analysis between Through-Hole Technology (PTH) and Surface-Mount Device (SMD) manufacturing reveals that SMD generally offers lower production costs due to automated assembly and reduced material usage. PTH requires more labor-intensive processes and higher quantities of raw materials, resulting in elevated expenses. The cost efficiency of SMD becomes more pronounced in high-volume production, making it the preferred choice for large-scale electronic manufacturing.

Applications and Use Cases

PTH (Plated Through-Hole) technology excels in applications requiring strong mechanical bonds and high current handling, commonly used in power supplies, connectors, and components subjected to mechanical stress. SMD (Surface Mount Device) technology is preferred for miniaturized, high-density circuit designs in smartphones, laptops, and wearable electronics, enabling faster production and reduced board size. Both PTH and SMD are integral in hybrid circuits, optimizing durability and compactness across automotive, industrial, and consumer electronics sectors.

Future Trends in PCB Component Mounting Techniques

Future trends in PCB component mounting techniques emphasize the integration of PTH (Plated Through-Hole) and SMD (Surface Mount Device) methods to leverage reliability and miniaturization. Advances in high-density interconnect (HDI) technology drive the adoption of ultra-fine pitch SMDs, while improved PTH processes enhance mechanical strength for heavy components. Hybrid mounting solutions combining PTH and SMD enable optimized electrical performance and manufacturing efficiency in next-generation electronics.

Through-Hole Technology (THT)

Through-Hole Technology (THT) utilizes PTH components by inserting leads into drilled holes for robust mechanical and electrical connections, contrasting with Surface-Mount Devices (SMD) that are placed directly on PCB surfaces for compact design.

Surface-Mount Technology (SMT)

Surface-Mount Technology (SMT) offers higher component density, faster assembly, and improved electrical performance compared to traditional Plated Through-Hole (PTH) mounting methods.

Leaded Components

PTH (Plated Through-Hole) technology provides superior mechanical strength and reliability for leaded components compared to SMD (Surface-Mount Device) technology, especially in high-stress or high-vibration environments.

Reflow Soldering

PTH (Plated Through-Hole) components offer stronger mechanical bonds for reflow soldering, while SMD (Surface Mount Devices) enable faster, more efficient assembly with precise solder joint formation.

Wave Soldering

Wave soldering efficiency is significantly enhanced by using Selective Metal Deposition (SMD) over Pin-Through-Hole (PTH) components, due to better thermal profiles and reduced solder bridging.

Pick-and-Place

Pick-and-Place machines excel in high-speed component placement for Surface-Mount Devices (SMD) due to precise robotic arms, while Pin Through-Hole (PTH) assembly relies more on manual or wave soldering techniques.

Plated Through Hole (PTH)

Plated Through Hole (PTH) technology offers superior mechanical strength and reliable electrical connections by plating the interior of drilled holes, making it ideal for heavy components compared to Surface-Mount Devices (SMD) that rely on soldered pads without through-hole plating.

Solder Paste

SMD solder paste offers precise metal alloy dispersion and flux composition optimized for reflow soldering, ensuring superior joint reliability and consistent solder volume compared to PTH processes.

Component Footprint

PTH components have larger, through-hole footprints requiring drilling, while SMD components feature compact, flat footprints optimized for surface mounting and higher PCB density.

Assembly Density

PTH assemblies typically offer lower component density compared to SMD assemblies due to larger lead sizes and dual-side mounting limitations.

PTH vs SMD Infographic

njnir.com

njnir.com