Isolated power supplies provide galvanic separation between input and output, enhancing safety and reducing noise interference in sensitive electrical systems. Non-isolated power supplies share a common ground, offering simpler design and higher efficiency but less protection against voltage spikes and ground loops. Choosing between isolated and non-isolated power supplies depends on application requirements such as safety standards, noise immunity, and system complexity.

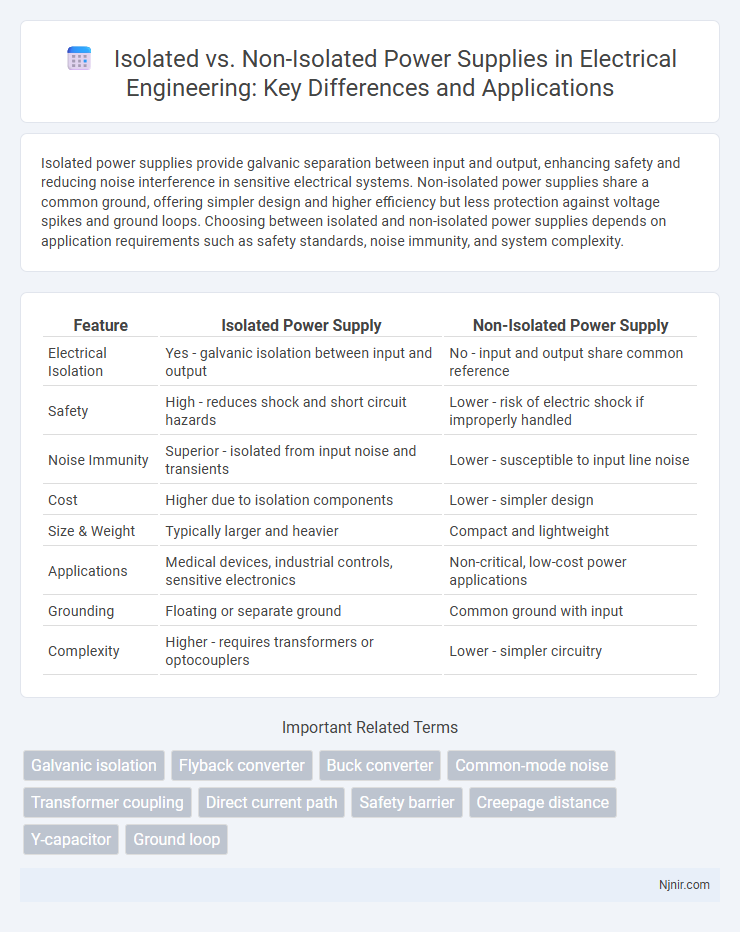

Table of Comparison

| Feature | Isolated Power Supply | Non-Isolated Power Supply |

|---|---|---|

| Electrical Isolation | Yes - galvanic isolation between input and output | No - input and output share common reference |

| Safety | High - reduces shock and short circuit hazards | Lower - risk of electric shock if improperly handled |

| Noise Immunity | Superior - isolated from input noise and transients | Lower - susceptible to input line noise |

| Cost | Higher due to isolation components | Lower - simpler design |

| Size & Weight | Typically larger and heavier | Compact and lightweight |

| Applications | Medical devices, industrial controls, sensitive electronics | Non-critical, low-cost power applications |

| Grounding | Floating or separate ground | Common ground with input |

| Complexity | Higher - requires transformers or optocouplers | Lower - simpler circuitry |

Introduction to Power Supply Topologies

Isolated power supply topologies electrically separate the input from the output, providing safety and noise reduction advantages, crucial for medical, industrial, and communication equipment. Non-isolated power supplies share a common ground between input and output, offering simpler designs and higher efficiency for low-voltage applications like DC-DC converters in consumer electronics. Choosing between isolated and non-isolated topologies depends on application requirements such as safety standards, voltage levels, and electromagnetic interference considerations.

Defining Isolated Power Supplies

Isolated power supplies provide electrical separation between input and output circuits, preventing direct current flow and minimizing noise interference, which enhances safety and signal integrity in sensitive applications. They achieve isolation through transformers or optocouplers, ensuring that faults or surges in one circuit do not affect the other. This contrasts with non-isolated power supplies, where the input and output share a common ground, increasing efficiency but reducing protection against electrical noise and ground loops.

Understanding Non-isolated Power Supplies

Non-isolated power supplies share a common ground between input and output, resulting in a direct electrical connection that allows for simpler design and higher efficiency. These power supplies are typically used in applications where input and output voltages are closely related, allowing for compact size and cost-effectiveness. Understanding the operational limitations, such as limited safety isolation and increased noise susceptibility, is crucial when selecting a non-isolated power supply for sensitive or high-voltage environments.

Key Differences Between Isolated and Non-isolated Designs

Isolated power supplies feature galvanic isolation between input and output, preventing direct electrical connection and enhancing safety by reducing noise, ground loops, and potential shock hazards. Non-isolated power supplies share a common ground, resulting in simpler design, higher efficiency, and lower cost but with increased risk of noise interference and safety concerns. Key differences include isolation presence, complexity, cost, noise immunity, and typical applications where isolated designs suit medical and industrial equipment while non-isolated solutions are ideal for low-cost, less critical electronics.

Advantages of Isolated Power Supplies

Isolated power supplies provide enhanced safety by preventing direct electrical connection between input and output, reducing the risk of electric shock and equipment damage. They offer superior noise reduction and improved signal integrity, making them ideal for sensitive electronic applications requiring stable and clean power. Their inherent design supports better fault tolerance and protection, essential for medical, industrial, and communication systems.

Benefits of Non-isolated Power Supplies

Non-isolated power supplies offer higher efficiency and smaller size by directly connecting the input and output grounds, reducing component count and complexity. These supplies provide cost-effective solutions ideal for applications where galvanic isolation is not mandatory, such as battery-powered devices and low-voltage circuits. Their simplicity facilitates easier design and troubleshooting, improving overall system reliability in non-critical isolation environments.

Typical Applications for Isolated Power Supplies

Isolated power supplies are commonly used in medical devices, industrial automation, and telecommunications to ensure safety and prevent ground loops by electrically separating input and output circuits. They are essential in sensitive measurement equipment and data acquisition systems where noise reduction and signal integrity are critical. Typical applications also include audio systems and renewable energy setups, where isolation enhances performance and protects end-user components.

Use Cases for Non-isolated Power Supplies

Non-isolated power supplies are ideal for low-voltage applications where the input and output share a common ground, such as in battery-powered devices, LED drivers, and embedded systems. They offer higher efficiency, smaller size, and lower cost compared to isolated power supplies but lack galvanic isolation needed for safety in high-voltage or noise-sensitive environments. Non-isolated designs are commonly used in DC-DC converters, point-of-load regulation, and situations requiring minimal complexity and compact power delivery solutions.

Safety and Regulatory Considerations

Isolated power supplies provide enhanced safety by electrically separating the input and output, minimizing the risk of electric shock and reducing noise interference, which is critical in medical and industrial applications meeting stringent IEC and UL standards. Non-isolated power supplies, while more efficient and compact, offer less protection against electrical faults, making them suitable for low-voltage applications where safety regulations are less rigorous. Compliance with regulatory standards such as IEC 60950-1 and IEC 61558 dictates the choice between isolated and non-isolated designs to ensure user safety and electromagnetic compatibility.

Choosing the Right Power Supply for Your Project

Selecting between isolated and non-isolated power supplies depends on the project's safety requirements and electrical noise sensitivity. Isolated power supplies provide galvanic isolation, reducing noise interference and enhancing user safety in medical or industrial applications, while non-isolated supplies offer higher efficiency and simpler design for low-risk, cost-sensitive projects. Evaluating factors such as voltage levels, system grounding, and regulatory compliance ensures the optimal power supply choice for reliable and safe operation.

Galvanic isolation

Galvanic isolation in isolated power supplies ensures no direct electrical connection between input and output, preventing ground loops and enhancing safety compared to non-isolated power supplies.

Flyback converter

Flyback converters in isolated power supplies provide galvanic isolation and better noise immunity, while non-isolated versions offer simpler design and lower cost but lack electrical isolation.

Buck converter

Isolated buck converters use transformers to separate input and output grounds, enabling voltage level shifting and enhanced safety, while non-isolated buck converters directly connect input and output grounds for simpler, more efficient step-down voltage regulation.

Common-mode noise

Isolated power supplies eliminate common-mode noise by providing galvanic separation between input and output, whereas non-isolated power supplies share a common reference, making them more susceptible to common-mode noise interference.

Transformer coupling

Isolated power supplies use transformer coupling to electrically separate input and output circuits for safety and noise reduction, while non-isolated power supplies lack this transformer barrier, providing direct electrical connection.

Direct current path

Isolated power supplies feature a transformer that physically separates the input and output, ensuring no direct current path, while non-isolated power supplies have a direct current path between input and output for simpler, more efficient power transfer.

Safety barrier

Isolated power supplies use transformers to provide galvanic isolation enhancing safety barriers by preventing direct electrical connection, while non-isolated power supplies lack this separation, increasing risk of electric shock or interference.

Creepage distance

Isolated power supplies feature larger creepage distances to prevent electrical arcing and enhance safety between input and output circuits, whereas non-isolated power supplies have minimal or no creepage distance due to their direct electrical connection.

Y-capacitor

Y-capacitors in isolated power supplies provide essential line-to-earth noise filtering without creating a direct galvanic connection, unlike in non-isolated power supplies where such capacitors may compromise safety and introduce ground loops.

Ground loop

Isolated power supplies prevent ground loops by electrically separating input and output grounds, while non-isolated power supplies share a common ground that can cause ground loop interference.

Isolated vs Non-isolated (power supply) Infographic

njnir.com

njnir.com