Synchronous motors operate at constant speed synchronized with the power supply frequency, offering precise speed control essential for applications requiring consistent performance. Asynchronous motors, or induction motors, run at speeds slightly less than the supply frequency, which makes them simpler, more robust, and cost-effective for general-purpose use. The choice between synchronous and asynchronous motors depends on factors like efficiency, speed regulation, and application-specific requirements.

Table of Comparison

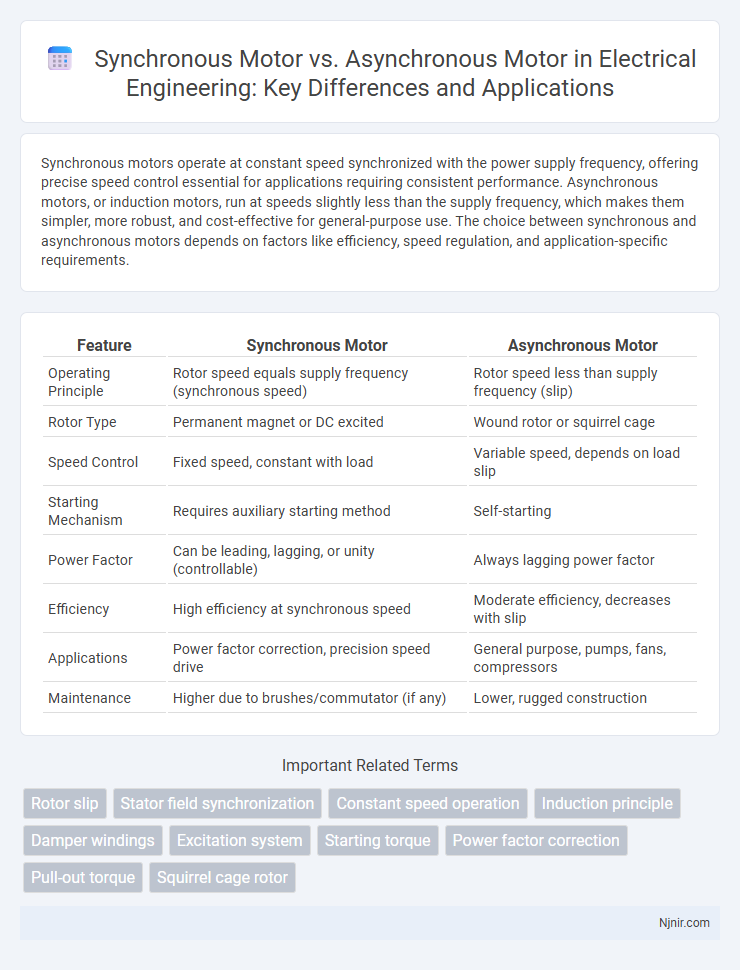

| Feature | Synchronous Motor | Asynchronous Motor |

|---|---|---|

| Operating Principle | Rotor speed equals supply frequency (synchronous speed) | Rotor speed less than supply frequency (slip) |

| Rotor Type | Permanent magnet or DC excited | Wound rotor or squirrel cage |

| Speed Control | Fixed speed, constant with load | Variable speed, depends on load slip |

| Starting Mechanism | Requires auxiliary starting method | Self-starting |

| Power Factor | Can be leading, lagging, or unity (controllable) | Always lagging power factor |

| Efficiency | High efficiency at synchronous speed | Moderate efficiency, decreases with slip |

| Applications | Power factor correction, precision speed drive | General purpose, pumps, fans, compressors |

| Maintenance | Higher due to brushes/commutator (if any) | Lower, rugged construction |

Introduction to Synchronous and Asynchronous Motors

Synchronous motors operate at a constant speed synchronized with the supply frequency, making them ideal for applications requiring precise speed control. Asynchronous motors, also known as induction motors, run at speeds slightly less than the supply frequency, offering ruggedness and simplicity for most industrial uses. The fundamental difference lies in rotor speed: synchronous motors maintain synchronization with the magnetic field, while asynchronous motors rely on slip for torque generation.

Fundamental Operating Principles

Synchronous motors operate by rotating at a speed directly proportional to the frequency of the supply current, maintaining synchronism with the rotating magnetic field due to a constant rotor magnetic field generated by direct current excitation. Asynchronous motors, also known as induction motors, rely on the slip between the rotor speed and the stator's rotating magnetic field to induce current in the rotor, creating torque through electromagnetic induction. The fundamental difference lies in synchronous speed operation for synchronous motors, while asynchronous motors always operate below synchronous speed due to slip.

Construction Differences

Synchronous motors feature rotor construction with permanent magnets or salient poles energized by DC supply, enabling the rotor to rotate in sync with the stator's magnetic field, while asynchronous motors have squirrel-cage rotors with short-circuited bars causing slip between rotor speed and magnetic field. The stator windings in both motors are similar, but synchronous motors require an external DC excitation system for the rotor, unlike asynchronous motors that rely solely on induced current. This fundamental construction difference affects their operational characteristics and applications in industrial drives.

Speed Characteristics and Control

Synchronous motors operate at a constant speed determined by the supply frequency and rotor pole count, maintaining synchronism with the stator's rotating magnetic field, which allows precise speed control in applications requiring fixed speeds. Asynchronous motors, or induction motors, run at speeds slightly less than synchronous speed due to slip, which varies with load, making their speed less constant but simpler and cheaper to control using variable frequency drives. The inherent slip in asynchronous motors enables easy torque control and speed variation, while synchronous motors require more complex control strategies like excitation adjustments for speed regulation.

Power Factor and Efficiency

Synchronous motors maintain a constant power factor close to unity by adjusting the excitation, enhancing overall system efficiency and reducing reactive power demand. Asynchronous motors typically operate at a lagging power factor, which can decrease efficiency and increase energy losses due to reactive current flow. The higher efficiency of synchronous motors under varying loads makes them preferable for power-critical industrial applications.

Starting Methods and Requirements

Synchronous motors require external starting methods such as pony motors or variable frequency drives to reach synchronous speed before locking in, as they cannot start on their own due to the need for rotor magnetic field synchronization with the stator. Asynchronous motors, or induction motors, employ direct-on-line starting, star-delta starters, or soft starters, relying on electromagnetic induction to generate rotor current and torque from standstill without additional devices. The starting current requirement for asynchronous motors is significantly higher, often 5 to 7 times the rated current, whereas synchronous motors have lower starting current but depend on external mechanisms for initial acceleration.

Applications in Industry

Synchronous motors are widely used in applications requiring precise speed control and constant speed, such as in robotics, conveyor systems, and synchronous clocks, due to their ability to maintain synchronous speed with the supply frequency. Asynchronous motors, also known as induction motors, dominate industrial applications like pumps, fans, compressors, and machine tools because of their robust design, lower cost, and ease of maintenance. The choice between synchronous and asynchronous motors depends on the need for speed accuracy, efficiency, and load type in industrial environments.

Advantages and Limitations

Synchronous motors offer precise speed control and high efficiency due to their constant rotor speed matching the supply frequency, making them ideal for applications requiring accurate timing and power factor correction. Asynchronous motors, or induction motors, are simpler, more rugged, and cost-effective, with self-starting capability and less maintenance, but they experience slip during operation, causing less efficient speed regulation. Limitations of synchronous motors include complex starting mechanisms and higher initial costs, whereas asynchronous motors have lower efficiency under varying loads and limited control over speed.

Maintenance and Reliability

Synchronous motors require precise maintenance of their excitation system to ensure consistent rotor alignment and reliable performance, often demanding more specialized skillsets compared to asynchronous motors. Asynchronous motors, also known as induction motors, offer higher reliability with less frequent maintenance due to their rugged construction and absence of brushes or slip rings. Maintenance of asynchronous motors primarily involves regular inspection of bearings and rotor condition, making them a preferred choice for applications demanding lower upkeep and enhanced operational durability.

Selection Criteria for Motor Type

Synchronous motors are preferred when precise speed control and constant speed under varying loads are critical, such as in robotics or synchronous clocks, due to their ability to operate at synchronous speed. Asynchronous motors, or induction motors, are favored for cost-sensitive applications requiring robustness, simple construction, and lower maintenance, commonly found in industrial drives and household appliances. Selection criteria hinge on factors like speed accuracy, load type, efficiency, maintenance requirements, and initial cost, with synchronous motors excelling in efficiency and control, while asynchronous motors offer better reliability and ease of use.

Rotor slip

Rotor slip in asynchronous motors is essential for torque generation, whereas synchronous motors operate with zero slip, maintaining rotor speed exactly matched to the stator's rotating magnetic field.

Stator field synchronization

Synchronous motors maintain a constant speed by synchronizing the rotor with the stator's rotating magnetic field, whereas asynchronous motors operate with rotor speed lagging behind the stator field, causing slip.

Constant speed operation

Synchronous motors maintain constant speed regardless of load by matching supply frequency, while asynchronous motors experience speed variations due to slip between rotor and stator magnetic fields.

Induction principle

Synchronous motors operate at constant speed synchronized with the supply frequency through a rotor energized by direct current, while asynchronous motors, also known as induction motors, rely on electromagnetic induction to induce current in the rotor, causing it to rotate at a speed slightly less than the synchronous speed.

Damper windings

Damper windings in synchronous motors stabilize rotor oscillations and help start the motor by mimicking squirrel-cage behavior, while asynchronous motors inherently use rotor bars to create self-starting torque without the need for separate damper windings.

Excitation system

Synchronous motors use an externally supplied excitation system to create a constant magnetic field for rotor synchronization, whereas asynchronous motors rely on induced currents in the rotor without external excitation, resulting in slip between rotor speed and stator magnetic field.

Starting torque

Synchronous motors provide constant starting torque through excitation control, whereas asynchronous motors generate starting torque via rotor slip and typically exhibit higher initial torque.

Power factor correction

Synchronous motors provide superior power factor correction by operating at leading or unity power factor, unlike asynchronous motors that typically have a lagging power factor due to rotor-induced lagging currents.

Pull-out torque

Synchronous motors typically exhibit a higher pull-out torque compared to asynchronous motors due to their ability to maintain constant speed under varying loads.

Squirrel cage rotor

Synchronous motors maintain constant rotor speed matching the stator's rotating magnetic field, while asynchronous motors with squirrel cage rotors operate at slip speed below synchronous speed for torque generation.

Synchronous motor vs Asynchronous motor Infographic

njnir.com

njnir.com