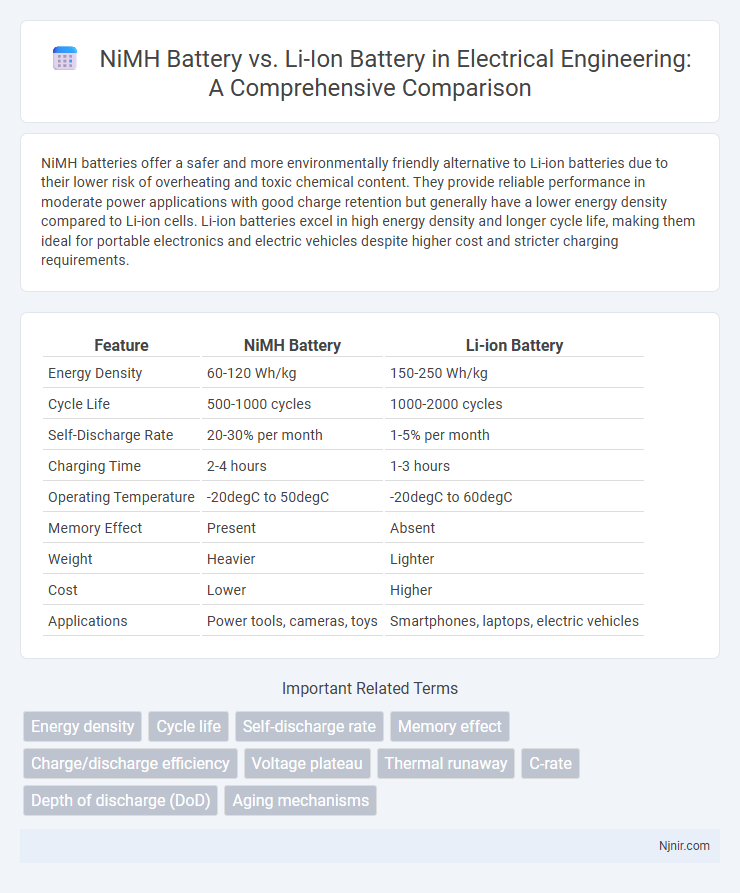

NiMH batteries offer a safer and more environmentally friendly alternative to Li-ion batteries due to their lower risk of overheating and toxic chemical content. They provide reliable performance in moderate power applications with good charge retention but generally have a lower energy density compared to Li-ion cells. Li-ion batteries excel in high energy density and longer cycle life, making them ideal for portable electronics and electric vehicles despite higher cost and stricter charging requirements.

Table of Comparison

| Feature | NiMH Battery | Li-ion Battery |

|---|---|---|

| Energy Density | 60-120 Wh/kg | 150-250 Wh/kg |

| Cycle Life | 500-1000 cycles | 1000-2000 cycles |

| Self-Discharge Rate | 20-30% per month | 1-5% per month |

| Charging Time | 2-4 hours | 1-3 hours |

| Operating Temperature | -20degC to 50degC | -20degC to 60degC |

| Memory Effect | Present | Absent |

| Weight | Heavier | Lighter |

| Cost | Lower | Higher |

| Applications | Power tools, cameras, toys | Smartphones, laptops, electric vehicles |

Introduction to NiMH and Li-Ion Batteries

NiMH batteries use a hydrogen-absorbing alloy as the negative electrode, offering high capacity and environmental friendliness with less toxic materials compared to NiCd batteries. Li-ion batteries utilize lithium compounds in the cathode and graphite in the anode, enabling higher energy density, longer cycle life, and lighter weight for portable electronics. Both battery types power devices effectively, but Li-ion dominates consumer electronics due to superior energy performance and charging efficiency.

Chemical Composition and Structure

NiMH batteries utilize a hydrogen-absorbing alloy as the negative electrode and nickel oxyhydroxide as the positive electrode, with an alkaline electrolyte often composed of potassium hydroxide. Li-ion batteries consist of a graphite anode and a lithium metal oxide cathode, paired with a lithium salt dissolved in organic solvents as the electrolyte, enabling higher energy density and voltage. The distinct chemical compositions and structural designs influence their performance, rechargeability, and applications.

Energy Density Comparison

Li-ion batteries offer significantly higher energy density, typically around 150-250 Wh/kg, compared to NiMH batteries, which range between 60-120 Wh/kg. This higher energy density enables Li-ion cells to store more energy in a smaller, lighter package, making them ideal for portable electronics and electric vehicles. NiMH batteries, while less energy-dense, have advantages in cost and safety but fall short in performance where weight and size are critical.

Charge and Discharge Characteristics

NiMH batteries exhibit lower energy density but offer stable discharge voltage and are less sensitive to overcharging compared to Li-ion batteries, which provide higher energy density and faster charging rates. Li-ion batteries display a flatter discharge curve, maintaining voltage more consistently throughout use, whereas NiMH voltage declines gradually under load. Charge efficiency in Li-ion cells typically exceeds 90%, while NiMH batteries have lower charge efficiency and higher self-discharge rates, impacting overall performance during extended storage.

Cycle Life and Longevity

NiMH batteries typically offer around 500 to 1,000 charge cycles, while Li-ion batteries can achieve 1,000 to 2,000 cycles, reflecting superior cycle life. Li-ion batteries maintain higher capacity retention over time, resulting in longer overall longevity compared to NiMH cells. The enhanced energy density and lower self-discharge rates of Li-ion batteries contribute significantly to their extended lifespan in various applications.

Safety Features and Risks

NiMH batteries exhibit lower risk of thermal runaway and are less prone to overheating compared to Li-ion batteries, making them safer under abuse conditions. Li-ion batteries, while offering higher energy density and longer life, require sophisticated battery management systems to mitigate risks like overheating, short circuits, and potential explosion. Proper handling and advanced safety circuits in Li-ion technology are critical to minimize hazards associated with their chemical volatility.

Temperature Performance

NiMH batteries typically perform better at lower temperatures, maintaining capacity and delivering more consistent current compared to Li-ion batteries, which can experience reduced efficiency and capacity losses in cold conditions. Li-ion batteries offer superior thermal stability at moderate temperatures but are more sensitive to extreme heat, potentially leading to accelerated degradation and safety risks. Understanding the operating temperature range is crucial for selecting the appropriate battery technology for specific applications such as electric vehicles or portable electronics.

Environmental Impact and Recycling

NiMH batteries contain fewer toxic metals and are generally easier to recycle compared to Li-ion batteries, which often include cobalt and lithium that require specialized recycling processes to mitigate environmental harm. Li-ion batteries have a higher energy density, leading to longer usage cycles and less frequent replacement, potentially reducing overall waste generation. Recycling programs for both battery types aim to recover valuable materials, but the complexity and cost of Li-ion battery recycling remain significant challenges in minimizing their environmental footprint.

Cost Analysis and Market Availability

NiMH batteries generally have a lower upfront cost compared to Li-ion batteries, making them an economical choice for budget-sensitive applications. Li-ion batteries, however, offer higher energy density and longer lifecycle, leading to better long-term value despite higher initial expenses. In terms of market availability, Li-ion technology dominates consumer electronics and electric vehicles, while NiMH remains prevalent in affordable rechargeable devices and hybrid vehicles.

Application Suitability in Electrical Engineering

NiMH batteries provide reliable performance for applications requiring moderate energy density and high power output, commonly used in hybrid electric vehicles and portable power tools. Li-ion batteries offer superior energy density, lighter weight, and longer cycle life, making them ideal for high-performance electronics, electric vehicles, and renewable energy storage systems. Electrical engineers often select Li-ion cells for compact, energy-intensive designs, while NiMH batteries remain preferred in cost-sensitive or temperature-resilient applications.

Energy density

Li-ion batteries offer significantly higher energy density, typically 150-250 Wh/kg, compared to NiMH batteries which usually range around 60-120 Wh/kg, making Li-ion more efficient for compact, high-capacity applications.

Cycle life

NiMH batteries typically offer 500-1000 charge cycles, whereas Li-ion batteries can achieve 1000-2000 cycles, making Li-ion more durable for long-term use.

Self-discharge rate

NiMH batteries typically have a higher self-discharge rate of around 20-30% per month compared to Li-ion batteries, which lose about 1-5% per month, making Li-ion batteries more efficient for long-term energy retention.

Memory effect

NiMH batteries exhibit a moderate memory effect causing capacity loss if repeatedly recharged before full discharge, whereas Li-ion batteries have negligible memory effect, enabling more flexible charging cycles and longer overall lifespan.

Charge/discharge efficiency

Li-ion batteries typically offer higher charge/discharge efficiency of around 95%, compared to NiMH batteries, which average 70-80%, resulting in less energy loss and longer runtime for Li-ion.

Voltage plateau

NiMH batteries maintain a consistent voltage plateau around 1.2V per cell, while Li-ion batteries exhibit a higher voltage plateau typically between 3.6V and 3.7V per cell, impacting their overall energy density and application suitability.

Thermal runaway

Li-ion batteries are more susceptible to thermal runaway due to higher energy density and electrolyte volatility, whereas NiMH batteries exhibit greater thermal stability and lower risk of overheating.

C-rate

NiMH batteries typically have lower C-rates around 1C to 5C, limiting fast discharge capabilities compared to Li-ion batteries which support higher C-rates up to 10C or more for better rapid power delivery.

Depth of discharge (DoD)

Li-ion batteries typically allow a higher Depth of Discharge (DoD) of around 80-90%, enhancing usable capacity compared to NiMH batteries, which generally have a lower DoD of about 50-60%, limiting their effective energy utilization.

Aging mechanisms

NiMH batteries primarily degrade through electrode material deterioration and electrolyte decomposition, while Li-ion batteries suffer aging mainly from solid electrolyte interphase (SEI) layer growth, lithium plating, and cathode structural changes.

NiMH battery vs Li-ion battery Infographic

njnir.com

njnir.com