Crystal oscillators provide high frequency stability and low phase noise by utilizing quartz crystals, making them ideal for precise timing applications. MEMS oscillators offer advantages in size, shock resistance, and integration with semiconductor processes, allowing for greater reliability in harsh environments. Both technologies serve critical roles in electronics, with crystal oscillators favored for accuracy and MEMS oscillators chosen for durability and miniaturization.

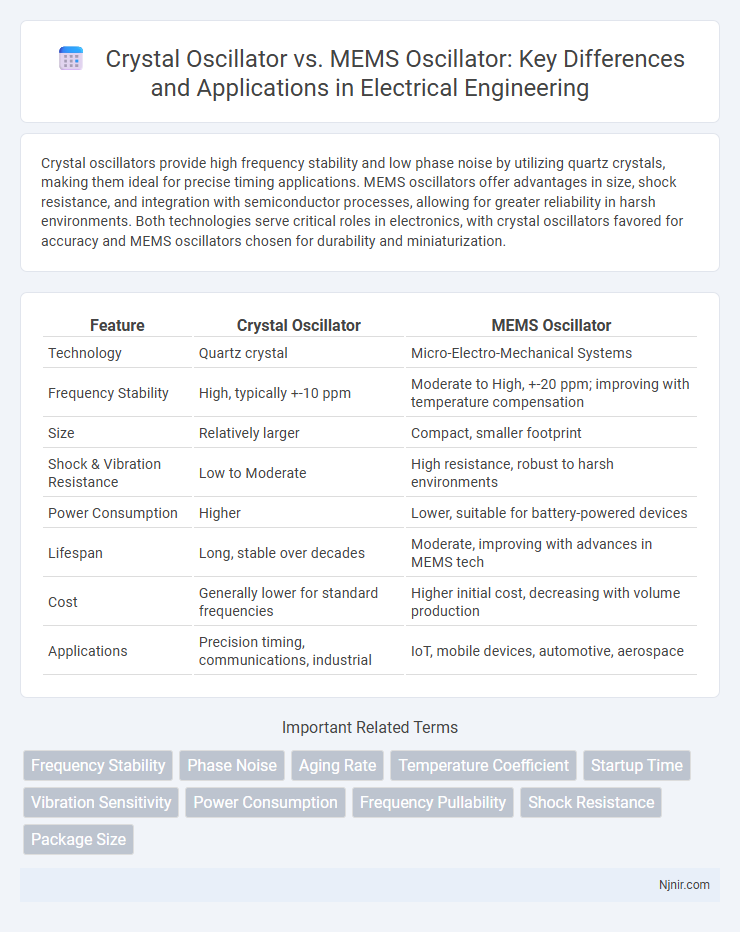

Table of Comparison

| Feature | Crystal Oscillator | MEMS Oscillator |

|---|---|---|

| Technology | Quartz crystal | Micro-Electro-Mechanical Systems |

| Frequency Stability | High, typically +-10 ppm | Moderate to High, +-20 ppm; improving with temperature compensation |

| Size | Relatively larger | Compact, smaller footprint |

| Shock & Vibration Resistance | Low to Moderate | High resistance, robust to harsh environments |

| Power Consumption | Higher | Lower, suitable for battery-powered devices |

| Lifespan | Long, stable over decades | Moderate, improving with advances in MEMS tech |

| Cost | Generally lower for standard frequencies | Higher initial cost, decreasing with volume production |

| Applications | Precision timing, communications, industrial | IoT, mobile devices, automotive, aerospace |

Introduction to Crystal and MEMS Oscillators

Crystal oscillators use quartz crystals to generate precise frequency signals through piezoelectric resonance, offering high stability and low phase noise ideal for communication systems and timing applications. MEMS oscillators rely on microelectromechanical systems technology, utilizing tiny vibrating structures fabricated on silicon chips, which provide better shock resistance, smaller size, and integration capability with semiconductor circuits. Both oscillator types serve critical roles in electronics, with crystal oscillators favored for long-term stability and MEMS oscillators preferred for robustness and flexibility in modern compact devices.

Fundamental Working Principles

Crystal oscillators use the piezoelectric effect of quartz crystals to generate precise, stable frequency signals by mechanically vibrating at a natural resonant frequency. MEMS oscillators rely on micro-electromechanical systems technology, utilizing tiny vibrating silicon structures controlled electronically to produce clock signals with high integration and environmental robustness. Both provide timing reference signals, but MEMS oscillators offer enhanced resistance to shock, vibration, and temperature variations due to their solid-state construction.

Construction and Materials

Crystal oscillators utilize quartz crystal as their resonating element, which is precisely cut and mounted inside a hermetically sealed package to ensure stability and reduce environmental interference. MEMS oscillators, on the other hand, use microelectromechanical systems fabricated from silicon wafers, incorporating tiny mechanical resonators and integrated circuitry on a single chip. The quartz material in crystal oscillators provides high Q-factor and frequency stability, while MEMS devices benefit from compact, robust silicon construction that offers better shock resistance and integration capabilities.

Frequency Stability Comparison

Crystal oscillators exhibit superior frequency stability due to their high-quality quartz resonators, maintaining frequency accuracy within a few parts per million (ppm) over temperature variations. MEMS oscillators, while offering better mechanical robustness and resistance to shock and vibration, typically have slightly lower frequency stability, ranging from 10 to 50 ppm depending on the design and packaging. For applications requiring ultra-precise timing, crystal oscillators remain the preferred choice, whereas MEMS oscillators provide a reliable alternative where environmental durability is critical.

Size and Integration Capabilities

MEMS oscillators offer significantly smaller form factors compared to traditional crystal oscillators, enabling more compact device designs. Their integration capabilities extend beyond timing functions, allowing seamless incorporation with other microelectromechanical systems on a single chip. Crystal oscillators, while larger and bulkier, provide high-frequency stability but lack the multi-functional integration flexibility inherent in MEMS technology.

Power Consumption Differences

Crystal oscillators generally consume more power due to their reliance on quartz crystal vibration, which requires a stable drive level and supporting circuitry. MEMS oscillators leverage micro-electromechanical systems technology, enabling significantly lower power consumption by operating at reduced voltages and integrating advanced CMOS circuits. Power efficiency in MEMS oscillators makes them ideal for battery-powered and portable applications where energy savings are critical.

Environmental Robustness and Reliability

MEMS oscillators exhibit superior environmental robustness compared to crystal oscillators, maintaining frequency stability under extreme temperature variations, high shock, and vibration conditions. Crystal oscillators, while traditionally reliable, are more susceptible to mechanical stress and aging effects that can degrade performance in harsh environments. MEMS technology offers enhanced reliability with smaller form factors and improved resistance to moisture, making it ideal for applications requiring long-term stability and durability.

Performance in High-Frequency Applications

Crystal oscillators deliver exceptional frequency stability and low phase noise, making them ideal for high-frequency applications requiring precise timing. MEMS oscillators offer improved mechanical robustness and lower power consumption while maintaining competitive phase noise and jitter performance at high frequencies. The choice between the two depends on specific application requirements such as environmental tolerance, size constraints, and power efficiency.

Cost and Manufacturing Considerations

Crystal oscillators typically offer lower unit costs due to mature manufacturing processes and widespread material availability, making them ideal for high-volume production. MEMS oscillators, while initially more expensive, benefit from semiconductor fabrication techniques that enable integration with other components and batch processing, reducing costs as production scales. Cost considerations must also factor in yield rates and packaging complexities, with MEMS devices often providing advantages in miniaturization and environmental robustness.

Application-Specific Suitability

Crystal oscillators excel in high-precision timing applications such as telecommunications, GPS, and medical devices due to their superior frequency stability and low phase noise. MEMS oscillators offer enhanced resistance to shock, vibration, and temperature variations, making them ideal for automotive, aerospace, and industrial IoT environments. Application-specific suitability depends on factors like frequency accuracy, environmental robustness, and power consumption requirements.

Frequency Stability

MEMS oscillators offer superior frequency stability over temperature and shock compared to traditional crystal oscillators due to their microelectromechanical design and integrated temperature compensation features.

Phase Noise

MEMS oscillators typically exhibit lower phase noise and better temperature stability compared to traditional crystal oscillators, making them ideal for precision applications requiring minimal signal distortion.

Aging Rate

MEMS oscillators typically demonstrate a lower aging rate of around +-1 ppm per year compared to traditional crystal oscillators, which often exhibit aging rates between +-3 to +-10 ppm per year.

Temperature Coefficient

Crystal oscillators exhibit temperature coefficients typically around +-20 ppm/degC, while MEMS oscillators offer superior temperature stability with coefficients as low as +-0.1 ppm/degC, enhancing performance in temperature-sensitive applications.

Startup Time

MEMS oscillators typically offer faster startup times than crystal oscillators, often achieving stable signal generation in microseconds compared to milliseconds required by crystal oscillators.

Vibration Sensitivity

MEMS oscillators typically exhibit lower vibration sensitivity than crystal oscillators due to their mechanically robust silicon-based design.

Power Consumption

MEMS oscillators typically consume less power than crystal oscillators, making them ideal for energy-sensitive applications such as mobile and IoT devices.

Frequency Pullability

Crystal oscillators typically have lower frequency pullability, maintaining stable frequency under varying environmental conditions, whereas MEMS oscillators exhibit higher frequency pullability, allowing more flexible frequency tuning but with increased susceptibility to environmental factors.

Shock Resistance

MEMS oscillators offer superior shock resistance compared to crystal oscillators due to their solid-state construction and lack of fragile quartz components.

Package Size

MEMS oscillators typically offer smaller package sizes than traditional crystal oscillators, making them ideal for compact electronic devices.

Crystal Oscillator vs MEMS Oscillator Infographic

njnir.com

njnir.com