Sweep Frequency Response Analysis (SFRA) offers detailed insights into transformer winding deformation and core issues by measuring the frequency response of the transformer. Transformer Turn Ratio (TTR) testing primarily evaluates the winding turns ratio to detect shorted turns or incorrect connections but does not provide frequency-based diagnostic data. SFRA complements TTR by identifying mechanical and electrical faults inside the transformer that TTR alone might miss, enabling a comprehensive assessment of transformer condition.

Table of Comparison

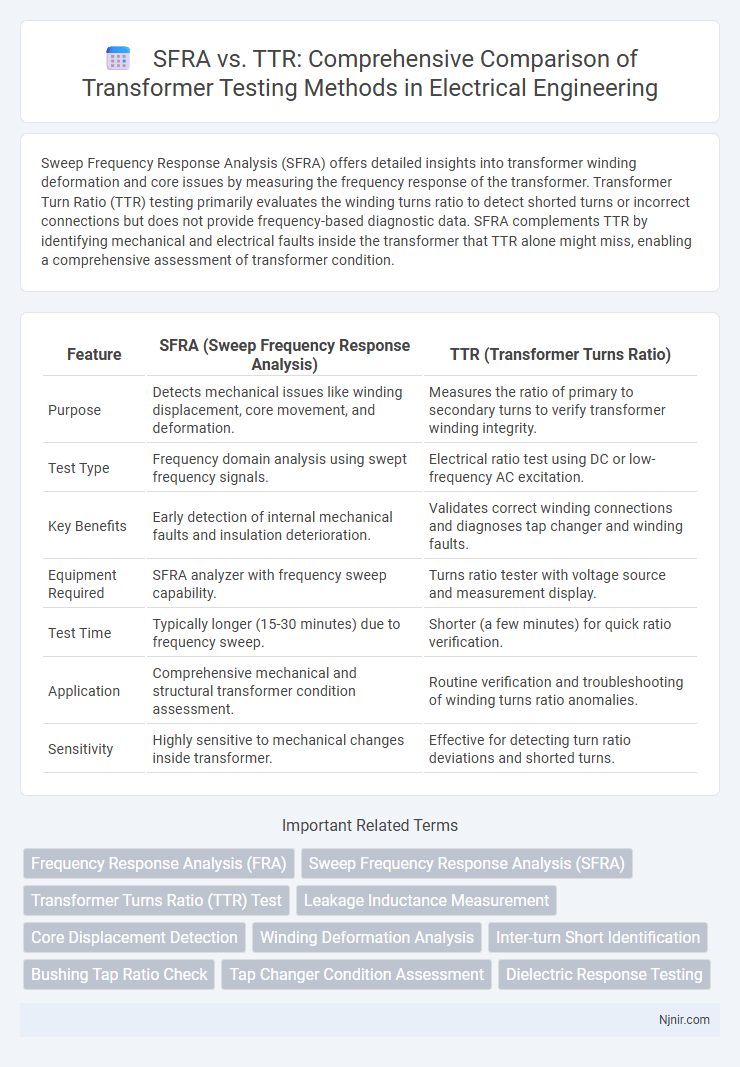

| Feature | SFRA (Sweep Frequency Response Analysis) | TTR (Transformer Turns Ratio) |

|---|---|---|

| Purpose | Detects mechanical issues like winding displacement, core movement, and deformation. | Measures the ratio of primary to secondary turns to verify transformer winding integrity. |

| Test Type | Frequency domain analysis using swept frequency signals. | Electrical ratio test using DC or low-frequency AC excitation. |

| Key Benefits | Early detection of internal mechanical faults and insulation deterioration. | Validates correct winding connections and diagnoses tap changer and winding faults. |

| Equipment Required | SFRA analyzer with frequency sweep capability. | Turns ratio tester with voltage source and measurement display. |

| Test Time | Typically longer (15-30 minutes) due to frequency sweep. | Shorter (a few minutes) for quick ratio verification. |

| Application | Comprehensive mechanical and structural transformer condition assessment. | Routine verification and troubleshooting of winding turns ratio anomalies. |

| Sensitivity | Highly sensitive to mechanical changes inside transformer. | Effective for detecting turn ratio deviations and shorted turns. |

Overview of Transformer Testing Methods

Transformer testing methods primarily include SFRA (Sweep Frequency Response Analysis) and TTR (Transformer Turn Ratio), each serving distinct diagnostic purposes. SFRA evaluates the mechanical integrity of transformer windings and core through frequency response measurement, effectively detecting winding displacement, core deformation, and insulation faults. TTR measures the ratio of voltages between transformer primary and secondary windings to verify proper turns ratio, crucial for identifying winding shorted turns, tap changer issues, and ensuring correct transformer operation.

Introduction to SFRA (Sweep Frequency Response Analysis)

Sweep Frequency Response Analysis (SFRA) is a diagnostic technique used to evaluate the integrity of transformer windings by measuring their frequency response over a wide range of frequencies. SFRA detects mechanical displacements, shorted turns, and core movements by analyzing changes in the transformer's impedance signature, making it essential for preventive maintenance. Compared to Transformer Testing and Ratio (TTR) which primarily assesses winding turns ratio, SFRA provides detailed insight into winding mechanical conditions and internal structural issues.

Understanding TTR (Transformer Turns Ratio) Testing

Transformer Turns Ratio (TTR) testing is a critical diagnostic method used to verify the correct turns ratio between transformer windings, ensuring proper voltage transformation and functionality. TTR testing involves applying a low-voltage AC signal to the primary winding and measuring the induced voltage in the secondary winding, which is then compared to the expected ratio based on design specifications. Accurate TTR measurements help identify winding faults, short circuits, and manufacturing defects, supporting reliable transformer operation and maintenance.

Key Principles Behind SFRA and TTR

SFRA (Sweep Frequency Response Analysis) utilizes frequency domain measurements to detect electrical anomalies by analyzing the system's impedance response across a range of frequencies, enabling early fault detection in transformers. Transformer Testing using TTR (Transformer Turns Ratio) focuses on measuring the ratio of primary to secondary voltage to assess winding integrity and detect shorted turns or faults in transformer windings. Both methods emphasize precise diagnostic evaluation, with SFRA targeting mechanical and insulation issues through frequency response and TTR concentrating on electrical consistency through voltage ratio measurements.

Applications of SFRA in Transformer Diagnostics

SFRA (Sweep Frequency Response Analysis) is extensively used for diagnosing internal transformer faults by detecting winding deformations, core problems, and insulation deterioration through frequency response comparison. Unlike TTR (Transformer Turns Ratio) testing, which primarily measures the ratio of primary to secondary windings to identify tap changer or shorted turn issues, SFRA provides a more detailed insight into mechanical and electrical integrity through comprehensive frequency domain signatures. Applications of SFRA in transformer diagnostics include early detection of winding displacement due to short-circuits, identification of core ground faults, and monitoring aging insulation that cannot be detected by conventional TTR testing alone.

Applications of TTR in Condition Assessment

Transformer Testing for Reliability (TTR) provides precise diagnostics in condition assessment of electrical transformers, enhancing predictive maintenance strategies by detecting insulation degradation and core faults early. TTR applications enable utilities to monitor transformer health through advanced data analysis, reducing unexpected failures and optimizing maintenance schedules. This approach integrates sensor data and machine learning models, improving asset lifespan and operational efficiency.

Comparative Analysis: SFRA vs TTR Effectiveness

SFRA (Sweep Frequency Response Analysis) and TTR (Transformer Testing using Transformer Testing Relay) both assess transformer condition but differ in approach and sensitivity. SFRA effectively detects mechanical deformations and winding displacements by analyzing frequency response signatures, while TTR primarily evaluates dielectric strength and insulation integrity through controlled testing. Comparative analysis reveals SFRA offers higher sensitivity to winding movements, whereas TTR excels in identifying insulation weaknesses, making them complementary techniques for comprehensive transformer diagnostics.

Advantages and Limitations of SFRA

SFRA (Sweep Frequency Response Analysis) excels in detecting transformer winding movement and insulation deterioration by analyzing frequency response signatures with high sensitivity to mechanical and electrical changes. Its advantages include non-invasiveness, rapid testing, and no need for transformer shutdown, enabling early fault detection without operational disruption. Limitations of SFRA involve sensitivity to test setup consistency, difficulty in interpreting results without baseline data, and reduced effectiveness in transformers with extensive tap changer positions or complex winding configurations compared to TTR (Transformer Turns Ratio) testing.

Advantages and Limitations of TTR

Transformer Testing (TTR) offers enhanced accuracy in fault detection by leveraging deep learning techniques to analyze complex patterns in transformer data, outperforming traditional SFRA methods in sensitivity and diagnostic precision. However, TTR requires extensive labeled datasets for training and significant computational resources, which may limit its practicality in real-time or resource-constrained environments. Despite these challenges, TTR's ability to detect subtle winding deformations and insulation faults positions it as a promising advancement in transformer condition monitoring.

Choosing the Right Test: SFRA or TTR for Your Transformer

SFRA (Sweep Frequency Response Analysis) and TTR (Transformer Turns Ratio) testing serve distinct purposes in transformer diagnostics, with SFRA ideal for detecting mechanical issues, winding displacement, and core problems, while TTR excels at verifying the electrical integrity of transformer windings and ensuring correct turns ratio. Selecting the appropriate test depends on the specific diagnostic requirement: SFRA provides detailed insight into winding deformation and mechanical integrity, whereas TTR offers precise validation of winding turn ratios to detect shorted or open turns. For comprehensive transformer health assessment, combining SFRA and TTR tests delivers optimized detection of both mechanical and electrical anomalies.

Frequency Response Analysis (FRA)

Frequency Response Analysis (FRA) in SFRA offers high-precision fault detection by measuring frequency-dependent impedance, whereas Transformer Testing using TTR primarily evaluates winding resistance and insulation integrity without detailed frequency spectrum insights.

Sweep Frequency Response Analysis (SFRA)

Sweep Frequency Response Analysis (SFRA) precisely measures transformer winding mechanical integrity and detects internal faults by analyzing frequency response signatures compared to baseline measurements.

Transformer Turns Ratio (TTR) Test

Transformer Turns Ratio (TTR) testing accurately measures the coil winding ratio to detect transformer winding faults and ensure proper voltage transformation efficiency.

Leakage Inductance Measurement

SFRA provides precise leakage inductance measurement by analyzing frequency response, whereas TTR uses transformer turn ratio testing, offering less sensitivity to leakage inductance variations.

Core Displacement Detection

SFRA provides precise core displacement detection by analyzing frequency response shifts, while TTR leverages transformer testing algorithms to identify displacement through time-domain signal variations.

Winding Deformation Analysis

SFRA accurately detects winding deformation by analyzing frequency response variations, whereas TTR leverages transformer testing through time-domain signal analysis to identify mechanical winding faults.

Inter-turn Short Identification

SFRA and TTR Transformer Testing methods differ in Inter-turn Short Identification accuracy, with SFRA providing more precise fault localization based on frequency response analysis.

Bushing Tap Ratio Check

The Bushing Tap Ratio Check in SFRA ensures accurate insulation and winding integrity assessment, while TTR (Transformer Turns Ratio) testing verifies the correct electrical ratio between windings to detect winding deformation or faults.

Tap Changer Condition Assessment

SFRA provides precise detection of mechanical defects in tap changers by analyzing frequency response signatures, while TTR leverages transformer testing techniques to evaluate tap changer condition through electrical measurements and performance trends.

Dielectric Response Testing

Dielectric Response Testing in SFRA provides precise insulation condition analysis by measuring frequency-dependent impedance, whereas TTR (Transformer Testing) uses transformer-specific tests like winding resistance and leakage reactance to evaluate overall transformer health.

SFRA vs TTR (Transformer Testing) Infographic

njnir.com

njnir.com