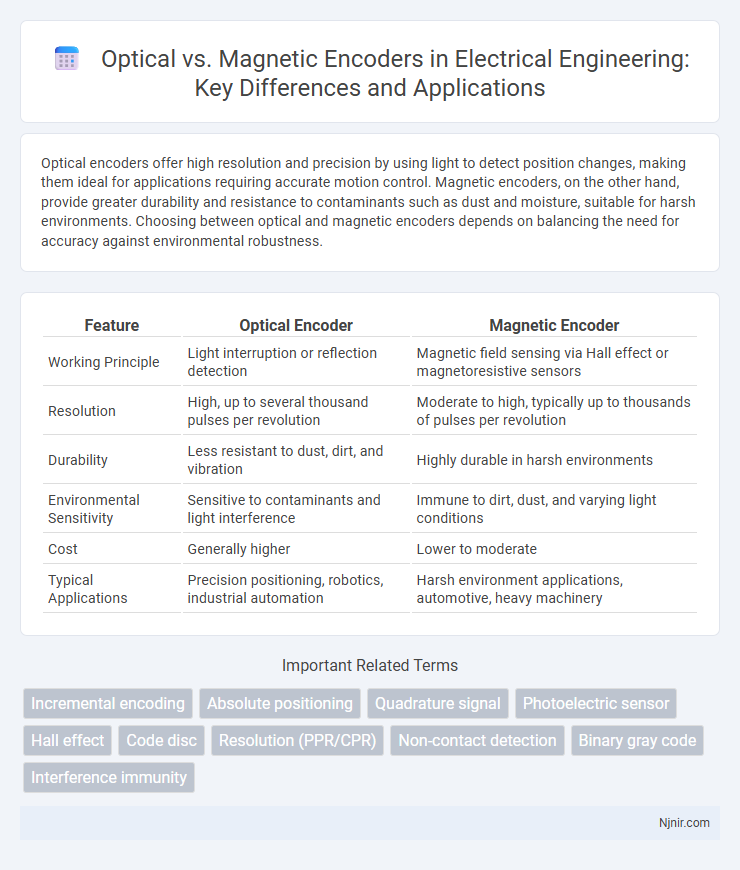

Optical encoders offer high resolution and precision by using light to detect position changes, making them ideal for applications requiring accurate motion control. Magnetic encoders, on the other hand, provide greater durability and resistance to contaminants such as dust and moisture, suitable for harsh environments. Choosing between optical and magnetic encoders depends on balancing the need for accuracy against environmental robustness.

Table of Comparison

| Feature | Optical Encoder | Magnetic Encoder |

|---|---|---|

| Working Principle | Light interruption or reflection detection | Magnetic field sensing via Hall effect or magnetoresistive sensors |

| Resolution | High, up to several thousand pulses per revolution | Moderate to high, typically up to thousands of pulses per revolution |

| Durability | Less resistant to dust, dirt, and vibration | Highly durable in harsh environments |

| Environmental Sensitivity | Sensitive to contaminants and light interference | Immune to dirt, dust, and varying light conditions |

| Cost | Generally higher | Lower to moderate |

| Typical Applications | Precision positioning, robotics, industrial automation | Harsh environment applications, automotive, heavy machinery |

Introduction to Encoders in Electrical Engineering

Encoders in electrical engineering are devices that convert mechanical motion into electrical signals, essential for position and speed feedback in automation systems. Optical encoders use light sensors and patterned discs to detect rotation with high precision and resolution, making them ideal for applications requiring accuracy. Magnetic encoders rely on magnetic fields and Hall-effect sensors, offering robustness in harsh environments and immunity to dust, dirt, and moisture.

Overview of Optical Encoders

Optical encoders use a light source, photodetector, and a patterned disc to convert angular position into electrical signals with high precision and resolution. These encoders are ideal for applications requiring accurate motion control, such as robotics and CNC machines. Compared to magnetic encoders, optical encoders offer superior accuracy but may be more sensitive to dust and environmental contaminants.

Overview of Magnetic Encoders

Magnetic encoders use magnetic fields to detect position and movement through sensors like Hall-effect or magnetoresistive elements, offering robust performance in harsh environments with dust, moisture, or vibration. Unlike optical encoders that rely on light and optical patterns, magnetic encoders provide enhanced durability, longer operational life, and immunity to contaminants. This makes magnetic encoders ideal for industrial automation, robotics, and automotive applications requiring reliable and maintenance-free position sensing.

Working Principles: Optical vs Magnetic Encoders

Optical encoders function by using a light source and a photodetector to sense interruptions or reflections on a coded disk, creating precise digital signals for position or speed measurement. Magnetic encoders operate with magnetoresistive or Hall Effect sensors detecting changes in the magnetic field from a rotating magnet attached to the shaft. Optical encoders typically offer higher resolution and accuracy due to direct light detection, while magnetic encoders provide robustness in harsh environments with dust, grease, or vibrations.

Accuracy and Resolution Comparison

Optical encoders generally offer higher accuracy and resolution due to their use of finely patterned codes on discs that provide precise position feedback, often achieving resolutions up to several thousand pulses per revolution (PPR). Magnetic encoders, while more robust to environmental contaminants and vibrations, typically have lower resolution and accuracy, usually ranging from a few hundred to a couple thousand PPR. The choice between optical and magnetic encoders depends on the application's precision requirements versus its tolerance for harsh operating conditions.

Environmental Suitability and Robustness

Optical encoders offer high precision but are more vulnerable to dust, dirt, and moisture, making them less suitable for harsh environments. Magnetic encoders provide enhanced robustness and can perform reliably in contaminants, vibrations, and temperature fluctuations, ideal for industrial and outdoor applications. Selection depends on environmental conditions, with magnetic encoders favored for durability and optical encoders preferred for high-resolution tasks in controlled settings.

Installation and Maintenance Considerations

Optical encoders require precise alignment and clean environments to ensure proper installation and reliable signal output, as contamination can affect their accuracy. Magnetic encoders offer more straightforward installation with less sensitivity to dust, dirt, and vibrations, reducing maintenance requirements in harsh conditions. Maintenance of optical encoders involves regular cleaning and inspection, while magnetic encoders typically need less frequent attention due to their robust, sealed designs.

Cost Differences and Market Availability

Optical encoders typically have higher manufacturing costs due to their precision components and complex optical sensors, making them more expensive than magnetic encoders, which use simpler Hall effect sensors and magnets. Magnetic encoders offer broader market availability in industrial automation and robotics because of their lower price points and robustness in harsh environments. Cost-sensitive applications often favor magnetic encoders, while high-precision requirements justify the premium pricing of optical encoders.

Typical Applications of Optical and Magnetic Encoders

Optical encoders are commonly used in high-precision applications such as CNC machines, robotics, and medical devices due to their high resolution and accuracy. Magnetic encoders excel in harsh environments like automotive systems, industrial machinery, and outdoor equipment because of their robustness to dust, dirt, and moisture. Both encoder types are essential in motion control systems, with optical encoders favored for clean, controlled settings and magnetic encoders preferred where durability and reliability are critical.

Choosing the Right Encoder for Your Electrical Project

Selecting the right encoder for your electrical project depends on accuracy requirements, environmental conditions, and budget constraints. Optical encoders provide high precision and are ideal for clean, controlled environments, while magnetic encoders offer robustness against dust, moisture, and vibrations, making them suitable for harsh industrial settings. Evaluating factors like resolution, durability, and maintenance needs ensures optimal performance and longevity in your application.

Incremental encoding

Incremental optical encoders provide higher resolution and accuracy using light sensors and slotted discs, while incremental magnetic encoders offer greater durability and resistance to contaminants with magnetic sensing technology.

Absolute positioning

Absolute optical encoders provide higher resolution and more precise absolute positioning compared to magnetic encoders, which offer robustness and cost-effectiveness but typically lower accuracy in absolute position measurement.

Quadrature signal

Quadrature optical encoders provide higher resolution and cleaner signals with less electrical noise compared to magnetic encoders, making them ideal for precision motion control applications.

Photoelectric sensor

Optical encoders use photoelectric sensors to detect light interruptions or reflections for precise position feedback, offering higher resolution and accuracy compared to magnetic encoders that rely on magnetic field variations.

Hall effect

Hall effect magnetic encoders provide robust, contactless position sensing with high durability and immunity to dust and vibration compared to optical encoders that offer higher resolution but are more sensitive to environmental contaminants.

Code disc

Optical encoders use a code disc with transparent and opaque segments to detect position via light interruption, while magnetic encoders utilize a code disc embedded with magnetic poles to sense position through magnetic field changes.

Resolution (PPR/CPR)

Optical encoders typically offer higher resolution up to 10,000 PPR compared to magnetic encoders, which usually provide maximum resolution around 1,000 CPR, making optical encoders ideal for precision applications.

Non-contact detection

Optical encoders utilize light-based non-contact detection for high-resolution position sensing, while magnetic encoders employ magnetic field-based non-contact detection to provide robust performance in harsh environments.

Binary gray code

Binary Gray code in optical encoders offers higher accuracy and noise immunity compared to magnetic encoders by minimizing signal errors during position changes.

Interference immunity

Magnetic encoders offer superior interference immunity compared to optical encoders due to their tolerance to dust, dirt, and harsh environmental conditions.

Optical vs Magnetic encoder Infographic

njnir.com

njnir.com