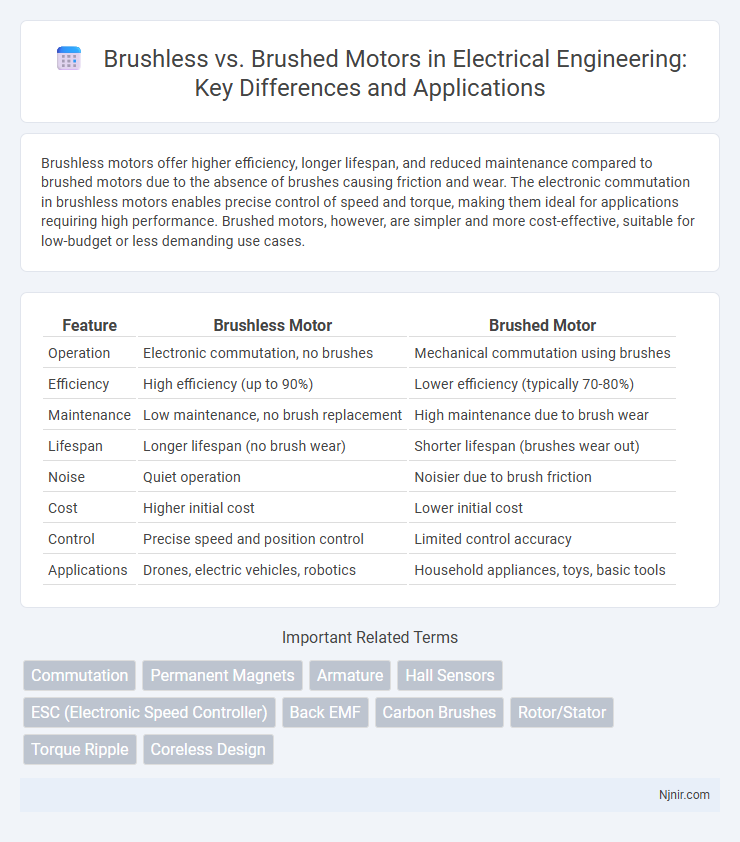

Brushless motors offer higher efficiency, longer lifespan, and reduced maintenance compared to brushed motors due to the absence of brushes causing friction and wear. The electronic commutation in brushless motors enables precise control of speed and torque, making them ideal for applications requiring high performance. Brushed motors, however, are simpler and more cost-effective, suitable for low-budget or less demanding use cases.

Table of Comparison

| Feature | Brushless Motor | Brushed Motor |

|---|---|---|

| Operation | Electronic commutation, no brushes | Mechanical commutation using brushes |

| Efficiency | High efficiency (up to 90%) | Lower efficiency (typically 70-80%) |

| Maintenance | Low maintenance, no brush replacement | High maintenance due to brush wear |

| Lifespan | Longer lifespan (no brush wear) | Shorter lifespan (brushes wear out) |

| Noise | Quiet operation | Noisier due to brush friction |

| Cost | Higher initial cost | Lower initial cost |

| Control | Precise speed and position control | Limited control accuracy |

| Applications | Drones, electric vehicles, robotics | Household appliances, toys, basic tools |

Introduction to Brushed and Brushless Motors

Brushed motors use carbon brushes that conduct electricity to the motor's armature, causing friction and wear over time, which limits their lifespan and efficiency. Brushless motors eliminate brushes by using electronic commutation, resulting in higher efficiency, reduced maintenance, and longer operational life. The design difference between brushed and brushless motors significantly impacts performance characteristics such as torque, speed control, and noise levels.

Core Design Differences

Brushless motors feature a rotor with permanent magnets and a stator with windings, enabling electronic commutation for precise control and higher efficiency. Brushed motors have a rotor with windings and use brushes and a commutator to switch current, resulting in mechanical wear and lower efficiency. The absence of brushes in brushless motors reduces friction, heat generation, and maintenance requirements compared to the core design of brushed motors.

Working Principles Explained

Brushless motors operate using electronic commutation where sensors detect rotor position and switch current through the stator windings, enabling smooth and efficient rotation without physical brushes. In contrast, brushed motors rely on mechanical commutation with brushes and a commutator to deliver current directly to the rotating armature, causing physical contact and wear. The absence of brushes in brushless motors reduces friction, increases lifespan, and improves energy efficiency compared to the traditional brushed motor design.

Efficiency Comparison

Brushless motors offer higher efficiency compared to brushed motors due to their reduced friction and heat generation, as they eliminate mechanical brushes and commutators. Brushless motors typically achieve efficiency rates of 85-90%, while brushed motors usually range between 65-75%, making brushless motors more energy-efficient and suitable for applications requiring longer battery life and lower maintenance. The enhanced efficiency of brushless motors results in less energy loss and improved performance in high-demand environments such as electric vehicles and drones.

Maintenance Requirements

Brushless motors require significantly less maintenance compared to brushed motors due to the absence of brushes that wear out over time. Brushed motors need regular inspection and replacement of brushes to prevent performance degradation and potential motor failure. The sealed design of brushless motors also reduces dust and debris accumulation, enhancing durability and reliability in various applications.

Lifespan and Durability

Brushless motors offer superior lifespan and durability compared to brushed motors due to the absence of brushes that wear out over time, resulting in less maintenance and longer operational life. The sealed design of brushless motors protects internal components from dust and debris, enhancing reliability in harsh environments. Brushed motors typically have shorter lifespans because friction and electrical sparking cause wear on brushes and commutators, leading to frequent replacements and reduced durability.

Performance and Speed Control

Brushless motors deliver higher performance with increased efficiency, reduced heat generation, and longer lifespan compared to brushed motors, due to the absence of brushes that cause friction and wear. Speed control in brushless motors is more precise and responsive, enabled by electronic commutation through sensors or sensorless controllers, whereas brushed motors rely on mechanical brushes limiting control accuracy. This results in brushless motors offering smoother operation and consistent torque across a wider speed range, ideal for applications demanding high speed and reliability.

Cost and Market Availability

Brushless motors generally have a higher upfront cost due to their advanced design and electronic controllers, but their longer lifespan and reduced maintenance often make them more cost-effective in the long term. Brushed motors are widely available and typically cheaper initially, making them popular for budget-conscious or low-demand applications. Market availability of brushed motors remains strong for traditional uses, while brushless motors dominate in high-performance sectors like drones, electric vehicles, and robotics due to their efficiency and reliability.

Common Applications

Brushless motors are widely used in drones, electric vehicles, and computer cooling systems due to their high efficiency, longer lifespan, and quieter operation. Brushed motors are common in household appliances, toys, and power tools because of their simplicity, lower cost, and ease of control. Industrial automation equipment and robotics often prefer brushless motors for precision and reduced maintenance requirements.

Choosing the Right Motor for Your Project

Brushless motors offer higher efficiency, longer lifespan, and lower maintenance compared to brushed motors, making them ideal for projects requiring precision and durability. Brushed motors provide a cost-effective solution with simpler control systems and are suitable for applications with limited budgets or less demanding performance needs. Evaluating factors such as torque requirements, speed control, noise levels, and power consumption helps determine the best motor type for your specific project.

Commutation

Brushless motors use electronic commutation for precise control and higher efficiency, while brushed motors rely on mechanical commutation through brushes and a commutator, resulting in more wear and maintenance.

Permanent Magnets

Brushless motors use permanent magnets on the rotor for higher efficiency and longer lifespan compared to brushed motors, which rely on brushes and commutators causing friction and wear.

Armature

Brushless motors achieve higher efficiency and durability by eliminating the traditional armature with brushes, unlike brushed motors where the armature's commutator and brushes cause friction and wear.

Hall Sensors

Brushless motors utilize Hall sensors for precise rotor position detection, enhancing efficiency and control compared to brushed motors that lack this sensor integration.

ESC (Electronic Speed Controller)

Brushless motors require specialized ESCs with sensorless or sensor-based control algorithms for precise commutation, while brushed motors use simpler ESCs that directly switch current through the motor brushes.

Back EMF

Brushless motors generate a more consistent and higher back EMF than brushed motors, improving efficiency and speed control in electric applications.

Carbon Brushes

Brushless motors eliminate the need for carbon brushes, reducing maintenance and increasing durability compared to brushed motors that rely on carbon brushes for electrical contact.

Rotor/Stator

Brushless motors feature a rotor with permanent magnets and a stator with wound coils, enhancing efficiency and reducing wear compared to brushed motors where the rotor has windings and the stator is a permanent magnet.

Torque Ripple

Brushless motors exhibit significantly lower torque ripple compared to brushed motors, resulting in smoother operation and enhanced precision in applications requiring consistent torque output.

Coreless Design

Coreless brushed motors offer higher efficiency and smoother operation compared to traditional brushed motors but lack the durability and low maintenance advantages of brushless motors with coreless designs.

Brushless vs Brushed Motor Infographic

njnir.com

njnir.com