Sensorless control in electrical engineering uses algorithms to estimate rotor position and speed without physical sensors, reducing system complexity and cost. Encoder feedback provides direct and precise measurement of the rotor position, enhancing accuracy and dynamic response in motor control systems. Choosing between sensorless control and encoder feedback depends on the application's precision requirements, environmental conditions, and budget constraints.

Table of Comparison

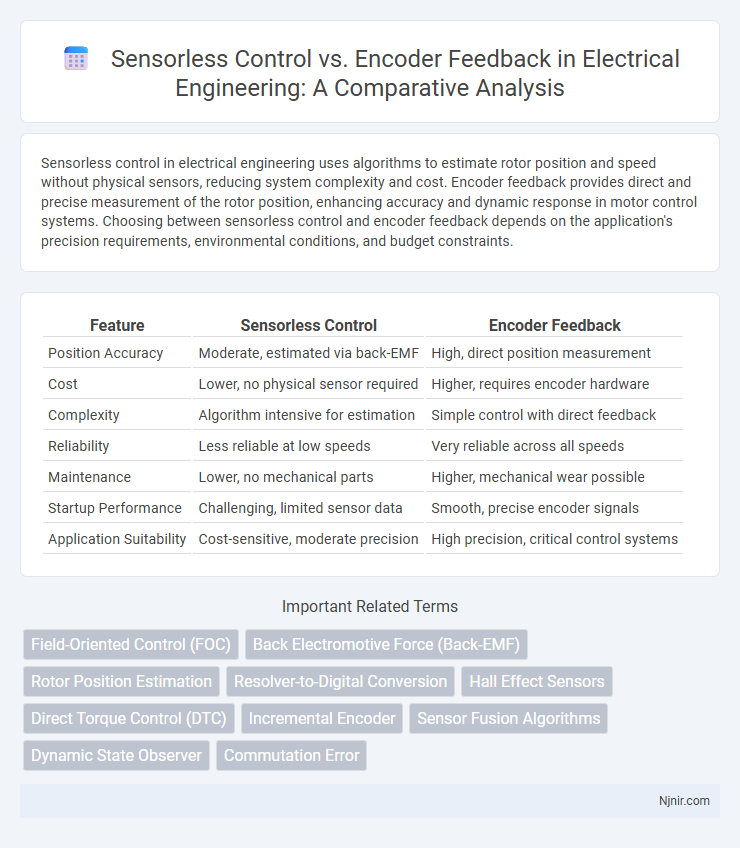

| Feature | Sensorless Control | Encoder Feedback |

|---|---|---|

| Position Accuracy | Moderate, estimated via back-EMF | High, direct position measurement |

| Cost | Lower, no physical sensor required | Higher, requires encoder hardware |

| Complexity | Algorithm intensive for estimation | Simple control with direct feedback |

| Reliability | Less reliable at low speeds | Very reliable across all speeds |

| Maintenance | Lower, no mechanical parts | Higher, mechanical wear possible |

| Startup Performance | Challenging, limited sensor data | Smooth, precise encoder signals |

| Application Suitability | Cost-sensitive, moderate precision | High precision, critical control systems |

Introduction to Motion Control Methods

Sensorless control in motion systems relies on estimating rotor position and speed using back-EMF or model-based algorithms, eliminating the need for physical sensors and reducing system cost and complexity. Encoder feedback provides precise and direct measurement of the rotor position and speed, enabling higher accuracy and robustness in closed-loop control, essential for applications demanding exact motion profiling. Balancing the trade-offs between sensorless control's cost-effectiveness and encoder feedback's precision is critical in selecting suitable motion control methods for industrial automation and robotics.

Fundamentals of Sensorless Control

Sensorless control relies on estimating rotor position and speed using algorithms that interpret motor voltage and current signals, eliminating the need for physical sensors or encoders. Common sensorless techniques include back-EMF zero-crossing detection, observer-based methods, and model reference adaptive systems (MRAS), which enhance reliability and reduce hardware costs in motor drive applications. This method is particularly effective at medium to high speeds but faces challenges in low-speed performance and dynamic response compared to encoder feedback systems.

Principles of Encoder Feedback

Encoder feedback operates by providing precise position and velocity data through sensors attached to the motor shaft, enabling accurate closed-loop control of motor speed and torque. This method enhances performance in applications requiring high precision by continuously monitoring rotor position and adjusting the drive accordingly. The use of quadrature encoders or absolute encoders ensures reliable real-time feedback, reducing errors caused by load variations or external disturbances.

Comparative Analysis: Accuracy and Precision

Sensorless control relies on estimation algorithms to determine rotor position and speed, often resulting in lower accuracy and precision compared to encoder feedback systems that provide direct measurement data. Encoder feedback offers high-resolution and real-time position information, enhancing control accuracy and enabling precise motor operation in applications requiring stringent performance. Variability in sensorless methods due to noise and parameter changes can reduce precision, making encoder feedback the preferred choice for critical and high-performance motion control tasks.

Cost Implications and System Complexity

Sensorless control reduces cost by eliminating encoders, lowering hardware and maintenance expenses, but may increase complexity in algorithms to accurately estimate rotor position. Encoder feedback provides precise rotor position data, simplifying control systems but raising overall system cost due to encoder procurement, installation, and integration. The trade-off between cost implications and system complexity depends on the application's precision requirements and budget constraints.

Reliability and Maintenance Considerations

Sensorless control eliminates the need for physical encoders, reducing mechanical failure points and lowering maintenance requirements, enhancing overall system reliability. Encoder feedback systems provide precise position and speed information, improving accuracy but introducing potential failure risks due to encoder wear, cable issues, or environmental factors. Maintenance considerations favor sensorless control in harsh or inaccessible environments, while encoder feedback demands regular inspection and calibration to maintain optimal performance.

Application Suitability and Industry Use Cases

Sensorless control techniques are well-suited for applications requiring low-cost, maintenance-free solutions, such as HVAC systems and basic industrial pumps, where precise position feedback is not critical. Encoder feedback systems provide high-accuracy position and speed data essential for robotics, CNC machines, and servo drives in automotive manufacturing and aerospace industries demanding precise motion control. The choice between sensorless and encoder feedback depends on the required control precision, environmental conditions, and cost constraints in specific industrial scenarios.

Performance in Dynamic and Harsh Environments

Sensorless control relies on estimating rotor position through motor back-EMF signals, which can result in reduced accuracy and slower response times in dynamic and harsh environments with rapid load changes or electrical noise. Encoder feedback provides precise rotor position data, enabling superior performance with fast dynamic response, high torque accuracy, and enhanced reliability under vibration, temperature extremes, and electromagnetic interference. Industrial applications requiring robust control in challenging conditions often favor encoder feedback systems for their improved stability and consistent performance.

Integration Challenges and Compatibility

Sensorless control systems face integration challenges due to reliance on algorithm accuracy and motor parameter variations, which may result in less precise position estimation compared to encoder feedback systems. Encoder feedback offers high compatibility with various motor types by providing direct mechanical position information, but integrating encoders often increases system complexity and cost. Ensuring seamless communication between controllers and sensors requires tailored interface protocols and careful consideration of electrical noise and signal interference in both methods.

Future Trends in Motor Control Technologies

Sensorless control techniques are advancing rapidly with the integration of machine learning algorithms and high-resolution estimation methods, enabling more precise rotor position and speed detection without physical sensors. Encoder feedback remains crucial for applications demanding high accuracy and reliability, but future trends focus on hybrid systems combining sensorless algorithms with minimal encoder data to reduce cost and increase robustness. Emerging motor control technologies are trending towards enhancing real-time adaptive control and fault detection capabilities, driven by improvements in embedded processing power and IoT connectivity.

Field-Oriented Control (FOC)

Sensorless control in Field-Oriented Control (FOC) relies on motor back-EMF estimation for rotor position, offering cost-effective and reduced maintenance benefits, while encoder feedback provides precise rotor angle measurement essential for high-accuracy torque and speed control in advanced FOC applications.

Back Electromotive Force (Back-EMF)

Sensorless control estimates rotor position using Back Electromotive Force (Back-EMF) signals, while encoder feedback provides direct mechanical position measurement for precise motor control.

Rotor Position Estimation

Sensorless control estimates rotor position using algorithms like Back-EMF or observer models, while encoder feedback provides direct, high-accuracy rotor position measurements for precise motor control.

Resolver-to-Digital Conversion

Sensorless control using Resolver-to-Digital Conversion enhances motor efficiency and reliability by eliminating the need for physical encoder feedback while maintaining precise rotor position estimation.

Hall Effect Sensors

Hall effect sensors provide reliable rotor position data for sensorless control systems by offering cost-effective, robust feedback compared to encoder-based methods.

Direct Torque Control (DTC)

Direct Torque Control (DTC) with sensorless control optimizes motor performance by estimating rotor position and speed without physical encoders, reducing hardware costs and enhancing reliability compared to encoder feedback systems.

Incremental Encoder

Sensorless control relies on motor parameter estimation without physical feedback, while incremental encoder feedback provides precise rotor position and speed measurements through electrical pulse signals for enhanced motor control accuracy.

Sensor Fusion Algorithms

Sensor fusion algorithms enhance sensorless control by integrating multiple data sources, improving motor accuracy and efficiency compared to traditional encoder feedback systems.

Dynamic State Observer

Dynamic State Observer enables sensorless control to estimate rotor position and speed accurately, reducing reliance on encoder feedback while maintaining high-performance motor operation.

Commutation Error

Sensorless control methods often experience higher commutation error compared to encoder feedback systems due to the lack of direct rotor position measurement, resulting in reduced accuracy and efficiency in motor commutation.

Sensorless control vs Encoder feedback Infographic

njnir.com

njnir.com