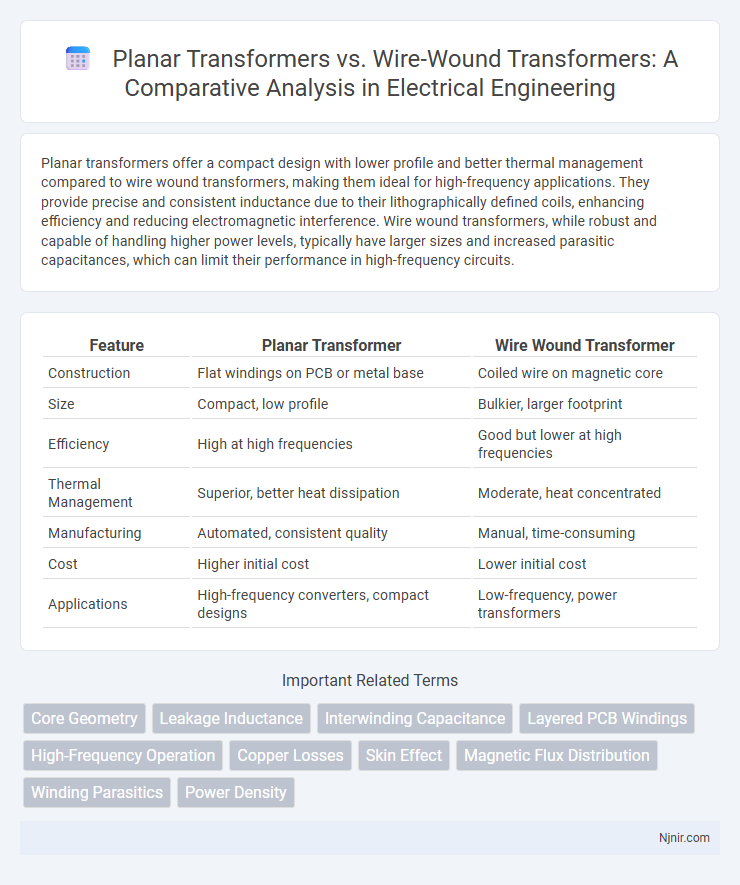

Planar transformers offer a compact design with lower profile and better thermal management compared to wire wound transformers, making them ideal for high-frequency applications. They provide precise and consistent inductance due to their lithographically defined coils, enhancing efficiency and reducing electromagnetic interference. Wire wound transformers, while robust and capable of handling higher power levels, typically have larger sizes and increased parasitic capacitances, which can limit their performance in high-frequency circuits.

Table of Comparison

| Feature | Planar Transformer | Wire Wound Transformer |

|---|---|---|

| Construction | Flat windings on PCB or metal base | Coiled wire on magnetic core |

| Size | Compact, low profile | Bulkier, larger footprint |

| Efficiency | High at high frequencies | Good but lower at high frequencies |

| Thermal Management | Superior, better heat dissipation | Moderate, heat concentrated |

| Manufacturing | Automated, consistent quality | Manual, time-consuming |

| Cost | Higher initial cost | Lower initial cost |

| Applications | High-frequency converters, compact designs | Low-frequency, power transformers |

Introduction to Planar and Wire Wound Transformers

Planar transformers utilize flat, spiral-shaped windings embedded in a printed circuit board (PCB), enabling high-frequency operation, compact size, and efficient thermal management, ideal for modern power electronics. Wire wound transformers consist of insulated copper wire coils wound around a magnetic core, providing robustness and higher power handling, commonly used in low-frequency and high-power applications. Both transformer types serve distinct applications, with planar transformers excelling in slim profiles and wire wound transformers preferred for durability and traditional designs.

Construction and Design Differences

Planar transformers feature a flat, compact design with windings and magnetic cores arranged in layered, printed circuit board (PCB) formats, enhancing heat dissipation and reducing electromagnetic interference. Wire wound transformers consist of traditional copper wire coils wound around a magnetic core, resulting in a bulkier structure with higher leakage inductance but simpler manufacturing. The planar transformer's design supports higher frequency applications due to its low profile and precise winding geometry, while wire wound transformers are preferred for lower frequency, higher power scenarios because of their robust and cost-effective construction.

Electrical Performance Comparison

Planar transformers exhibit lower parasitic capacitance and reduced leakage inductance compared to wire wound transformers, resulting in higher efficiency and improved high-frequency performance. Wire wound transformers typically have greater copper losses due to longer conductor lengths and increased skin effect at higher frequencies. Planar designs facilitate better thermal management and tighter winding geometries, enhancing electrical performance in compact power electronics applications.

Efficiency and Power Density

Planar transformers exhibit higher efficiency and superior power density compared to wire wound transformers due to their low-profile design and reduced parasitic losses. The planar structure allows for better thermal management and tighter winding configurations, which minimize leakage inductance and improve magnetic coupling. These characteristics make planar transformers ideal for compact, high-frequency power applications where maximizing efficiency and power density is critical.

Thermal Management and Heat Dissipation

Planar transformers offer superior thermal management due to their compact, low-profile design with enhanced surface area, enabling faster heat dissipation compared to traditional wire wound transformers. Wire wound transformers rely on copper wire coils and larger cores that generate hotspots and require additional cooling measures such as fans or heat sinks. The planar transformer's distributed winding and closer integration with PCB materials allow for more efficient heat spread and improved reliability in high-frequency, high-power applications.

Frequency Response and Applications

Planar transformers exhibit superior high-frequency response due to their low leakage inductance and reduced parasitic capacitance compared to wire wound transformers, making them ideal for high-speed switching power supplies and RF applications. Wire wound transformers, characterized by their robust construction and high power handling, perform better at low frequencies and are typically used in audio equipment, power distribution, and industrial machinery. The planar design's compact form factor and efficient thermal management further enhance its suitability for modern electronics requiring fast transient response and high power density.

Size, Weight, and Form Factor

Planar transformers offer a significantly smaller size and lower weight compared to wire wound transformers due to their flat, layered construction using PCB traces. The compact form factor of planar transformers enables efficient high-frequency operation and better thermal management, making them ideal for applications requiring miniaturization and high power density. Wire wound transformers, while typically bulkier and heavier due to their coiled copper wire and magnetic core design, provide robustness and are better suited for lower-frequency, high-current applications where size constraints are less critical.

Manufacturing Complexity and Cost

Planar transformers feature a compact, layered design using printed circuit boards, leading to automated, high-precision manufacturing that reduces labor costs and improves repeatability. Wire wound transformers rely on manual or semi-automated winding processes, resulting in longer production times and higher labor expenses. The material usage in planar transformers is optimized, lowering overall manufacturing costs compared to the bulkier, more labor-intensive wire wound transformers.

Reliability and Durability Considerations

Planar transformers exhibit superior reliability due to their low profile construction and consistent winding geometry, which reduces hotspots and mechanical stresses during operation. Wire wound transformers, while traditionally robust, are more prone to mechanical wear and insulation degradation over time because of their bulkier windings and susceptibility to vibration. The enhanced thermal management in planar transformers significantly contributes to increased durability, extending operational lifespan in high-frequency and high-temperature environments.

Selection Criteria for Specific Applications

Planar transformers offer high efficiency, compact size, and superior thermal performance, making them ideal for high-frequency power supplies and applications requiring miniaturization and lightweight designs. Wire wound transformers excel in handling high power levels, providing robustness and ease of customization, suitable for low-frequency applications and environments with high mechanical stress. Selecting between planar and wire wound transformers depends on factors like operating frequency, power density requirements, thermal management, and mechanical constraints specific to the application.

Core Geometry

Planar transformers feature flat, compact core geometry enabling higher frequency operation and improved thermal management, while wire-wound transformers use traditional wound cores with bulkier geometry, limiting frequency response and thermal efficiency.

Leakage Inductance

Planar transformers have significantly lower leakage inductance compared to wire wound transformers due to their compact, layered construction and minimal magnetic path length.

Interwinding Capacitance

Planar transformers exhibit significantly lower interwinding capacitance compared to wire wound transformers, enhancing high-frequency performance and reducing electromagnetic interference.

Layered PCB Windings

Planar transformers utilize layered PCB windings for compact, high-frequency performance with improved thermal management compared to bulkier, lower-frequency wire wound transformers.

High-Frequency Operation

Planar transformers offer superior high-frequency operation compared to wire wound transformers due to their low parasitic inductance, reduced leakage, and enhanced thermal management.

Copper Losses

Planar transformers exhibit significantly lower copper losses than wire wound transformers due to their flat conductor design, which reduces resistance and improves thermal management.

Skin Effect

Planar transformers exhibit reduced skin effect losses compared to wire wound transformers due to their flat conductor geometry, enabling higher efficiency at high frequencies.

Magnetic Flux Distribution

Planar transformers exhibit more uniform magnetic flux distribution with lower leakage inductance compared to traditional wire-wound transformers, enhancing efficiency and thermal management in compact electronic designs.

Winding Parasitics

Planar transformers exhibit lower winding parasitics such as reduced leakage inductance and inter-winding capacitance compared to wire wound transformers, enhancing high-frequency performance.

Power Density

Planar transformers offer significantly higher power density than wire wound transformers due to their compact design, lower parasitic inductance, and efficient heat dissipation.

Planar Transformer vs Wire Wound Transformer Infographic

njnir.com

njnir.com