Copper windings exhibit superior electrical conductivity and higher thermal resilience compared to aluminum, making them ideal for applications requiring efficient current flow and durability. Aluminum windings offer advantages in weight and cost, which are beneficial for large-scale transformers and motors where reduced mass is critical. The choice between copper and aluminum windings depends on balancing factors such as conductivity, mechanical strength, cost, and thermal performance in electrical engineering designs.

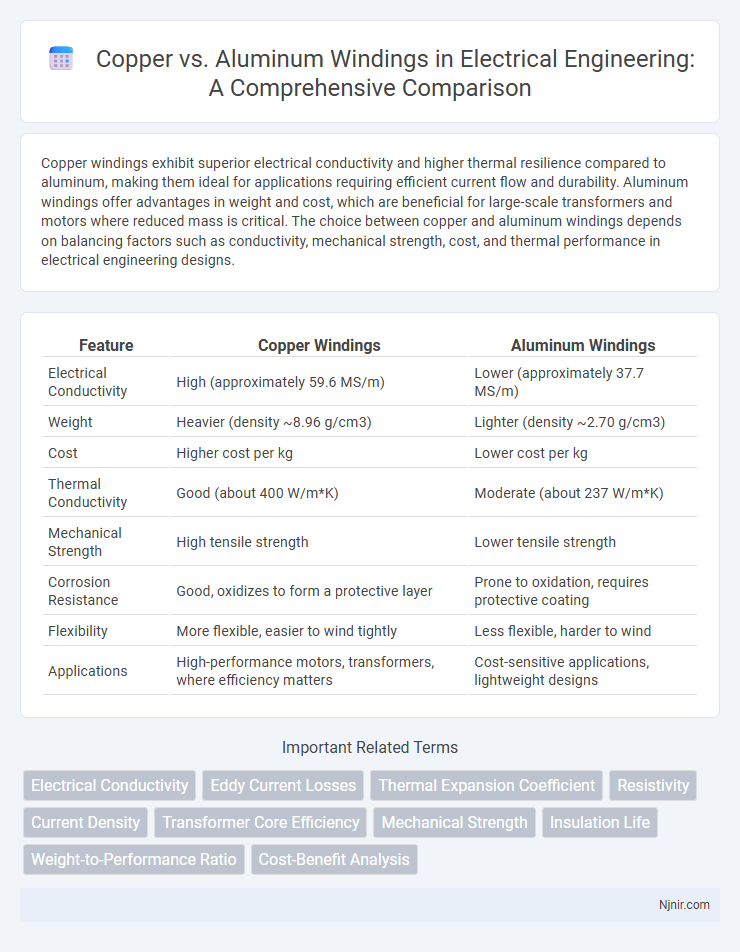

Table of Comparison

| Feature | Copper Windings | Aluminum Windings |

|---|---|---|

| Electrical Conductivity | High (approximately 59.6 MS/m) | Lower (approximately 37.7 MS/m) |

| Weight | Heavier (density ~8.96 g/cm3) | Lighter (density ~2.70 g/cm3) |

| Cost | Higher cost per kg | Lower cost per kg |

| Thermal Conductivity | Good (about 400 W/m*K) | Moderate (about 237 W/m*K) |

| Mechanical Strength | High tensile strength | Lower tensile strength |

| Corrosion Resistance | Good, oxidizes to form a protective layer | Prone to oxidation, requires protective coating |

| Flexibility | More flexible, easier to wind tightly | Less flexible, harder to wind |

| Applications | High-performance motors, transformers, where efficiency matters | Cost-sensitive applications, lightweight designs |

Introduction to Copper and Aluminum Windings

Copper windings offer superior electrical conductivity, mechanical strength, and thermal performance, making them ideal for high-efficiency electrical motors and transformers. Aluminum windings, while lighter and more cost-effective, have lower conductivity and require larger cross-sectional areas to match copper's performance. Understanding the material properties and application requirements is essential for optimizing winding design in electrical machinery.

Electrical Conductivity Comparison

Copper windings exhibit significantly higher electrical conductivity, approximately 59.6 million siemens per meter (MS/m), compared to aluminum windings at about 37.8 MS/m, enabling more efficient current flow and reduced energy losses. This higher conductivity of copper results in lower resistance and better performance in electrical machines, particularly in motors and transformers. Although aluminum windings are lighter and cost-effective, copper's superior conductivity ensures improved durability and thermal management in demanding electrical applications.

Thermal Conductivity and Heat Dissipation

Copper windings exhibit superior thermal conductivity, typically around 400 W/m*K, compared to aluminum's approximately 235 W/m*K, enhancing efficient heat dissipation in electrical motors and transformers. This higher thermal conductivity of copper minimizes hotspots and improves the overall operational lifespan by maintaining lower winding temperatures. Aluminum windings, although lighter and cost-effective, require larger cross-sectional areas to compensate for lower thermal performance, potentially affecting compact design efficiency.

Mechanical Strength and Durability

Copper windings exhibit superior mechanical strength and durability compared to aluminum, with higher tensile strength and resistance to fatigue under mechanical stress. This robustness allows copper windings to better withstand vibrations, thermal expansion, and operational wear, resulting in longer lifespan and reduced maintenance. Aluminum, while lighter and more cost-effective, is more prone to deformation and fatigue, making copper the preferred choice for high-stress electrical applications.

Weight Considerations in Electrical Components

Copper windings exhibit higher conductivity and energy efficiency but weigh approximately 50% more than aluminum windings, impacting the overall weight of electrical components. Aluminum's lower density significantly reduces the weight of motors and transformers, making it advantageous for applications where weight is critical, such as in aerospace or automotive industries. Designers must balance the trade-off between copper's performance benefits and aluminum's weight savings to optimize electrical component efficiency and durability.

Cost and Economic Factors

Copper windings offer superior electrical conductivity and durability but come at a higher material cost compared to aluminum, impacting the initial investment in electric motors and transformers. Aluminum windings provide a cost-effective alternative with lower raw material expenses and reduced weight, which can lead to savings in manufacturing and transportation. However, aluminum typically requires larger cross-sectional areas to achieve comparable performance, potentially offsetting cost advantages in some applications.

Corrosion Resistance and Longevity

Copper windings offer superior corrosion resistance compared to aluminum, as copper forms a stable oxide layer that protects against environmental degradation, enhancing longevity. Aluminum windings are more prone to oxidation and galvanic corrosion, which can compromise electrical conductivity and reduce the lifespan of windings in harsh conditions. Therefore, copper windings are preferred in applications demanding higher durability and extended service life, particularly in moist or corrosive environments.

Applications in Transformers and Motors

Copper windings in transformers and motors offer superior electrical conductivity, enhancing efficiency and reducing energy losses, making them ideal for high-performance and heavy-duty applications. Aluminum windings provide a lighter and cost-effective alternative, often used in larger transformers and motors where weight reduction and budget constraints are critical. Copper's durability and thermal conductivity result in better heat dissipation and longer lifespan compared to aluminum, which is more prone to oxidation and thermal expansion issues.

Installation and Maintenance Requirements

Copper windings offer superior conductivity and durability, resulting in easier installation due to their flexibility and resistance to fatigue during winding processes. Aluminum windings, while lighter and often more cost-effective, require more careful handling to prevent damage such as cracking or deformation during installation. Maintenance demands for copper windings are generally lower, given their higher thermal tolerance and reduced susceptibility to corrosion compared to aluminum counterparts.

Environmental Impact and Sustainability

Copper windings in electrical machines offer higher conductivity and durability, resulting in less energy loss and longer equipment life, which reduces overall environmental impact. Aluminum windings are lighter and cheaper, but their lower conductivity requires more material and frequent replacements, potentially increasing resource consumption and waste. Choosing copper supports sustainability goals by enhancing energy efficiency and minimizing material extraction, whereas aluminum's benefits are mainly cost and weight-related but may lead to greater ecological footprints over time.

Electrical Conductivity

Copper windings exhibit significantly higher electrical conductivity than aluminum windings, resulting in lower energy losses and improved efficiency in electrical motors and transformers.

Eddy Current Losses

Copper windings exhibit lower eddy current losses compared to aluminum windings due to copper's higher electrical conductivity and reduced resistive heating, enhancing overall motor efficiency.

Thermal Expansion Coefficient

Copper windings have a lower thermal expansion coefficient of approximately 16.5 x 10^-6 /degC compared to aluminum windings, which expand at about 23.1 x 10^-6 /degC, making copper more dimensionally stable under temperature variations in electrical machines.

Resistivity

Copper windings have significantly lower resistivity (approximately 1.68 uO*cm) compared to aluminum windings (around 2.82 uO*cm), resulting in higher electrical conductivity and improved efficiency in electrical machines.

Current Density

Copper windings offer higher current density than aluminum windings due to their superior electrical conductivity and lower resistivity.

Transformer Core Efficiency

Copper windings enhance transformer core efficiency by offering lower electrical resistance and improved conductivity compared to aluminum windings, reducing energy losses and heat generation.

Mechanical Strength

Copper windings offer superior mechanical strength compared to aluminum windings, making them more resistant to deformation and better suited for high-stress electrical applications.

Insulation Life

Copper windings exhibit superior insulation life compared to aluminum windings due to copper's lower electrical resistance and better thermal conductivity, which reduce heat buildup and prolong insulation durability.

Weight-to-Performance Ratio

Copper windings offer superior electrical conductivity and durability, resulting in a higher weight-to-performance ratio compared to lighter but less efficient aluminum windings.

Cost-Benefit Analysis

Copper windings offer higher conductivity and durability but at a 40-60% higher cost compared to aluminum, making aluminum windings a cost-effective choice for applications prioritizing budget over efficiency and lifespan.

Copper vs Aluminum Windings Infographic

njnir.com

njnir.com