Vacuum circuit breakers employ vacuum interrupters to extinguish arcs, offering fast recovery and minimal contact wear, which makes them ideal for medium-voltage applications. SF6 circuit breakers use sulfur hexafluoride gas to quench arcs, providing superior insulation and interruption capabilities suitable for high-voltage systems. While vacuum circuit breakers excel in environmental safety and low maintenance, SF6 circuit breakers provide better dielectric properties and are preferred for extremely demanding electrical grid conditions.

Table of Comparison

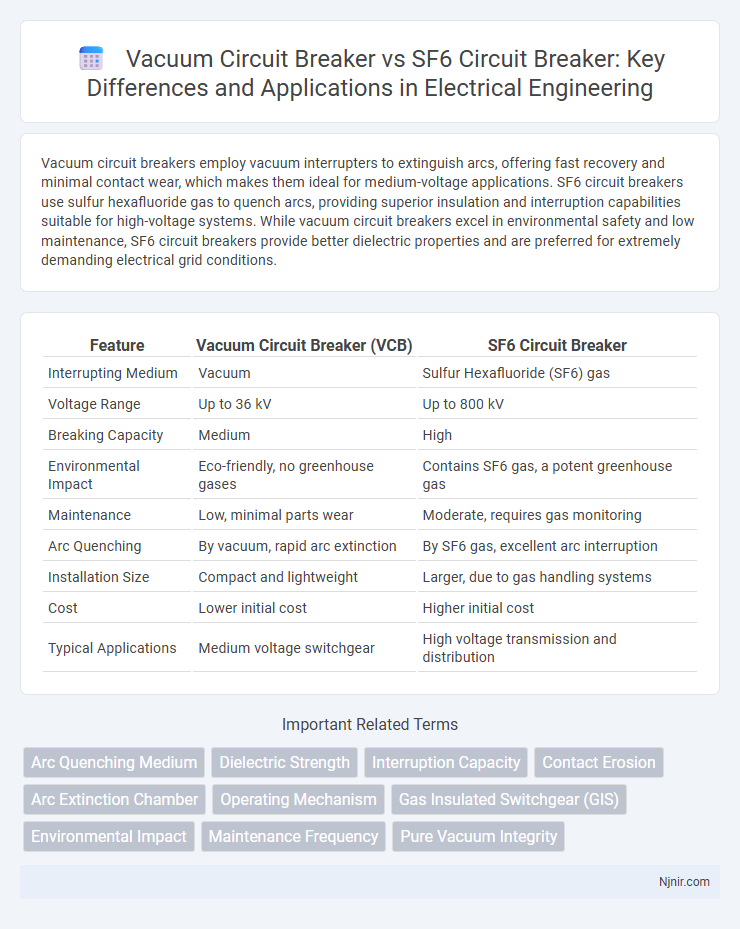

| Feature | Vacuum Circuit Breaker (VCB) | SF6 Circuit Breaker |

|---|---|---|

| Interrupting Medium | Vacuum | Sulfur Hexafluoride (SF6) gas |

| Voltage Range | Up to 36 kV | Up to 800 kV |

| Breaking Capacity | Medium | High |

| Environmental Impact | Eco-friendly, no greenhouse gases | Contains SF6 gas, a potent greenhouse gas |

| Maintenance | Low, minimal parts wear | Moderate, requires gas monitoring |

| Arc Quenching | By vacuum, rapid arc extinction | By SF6 gas, excellent arc interruption |

| Installation Size | Compact and lightweight | Larger, due to gas handling systems |

| Cost | Lower initial cost | Higher initial cost |

| Typical Applications | Medium voltage switchgear | High voltage transmission and distribution |

Introduction to Circuit Breaker Technologies

Vacuum circuit breakers utilize vacuum as the arc quenching medium, offering fast arc extinction and low maintenance requirements, making them suitable for medium voltage applications. SF6 circuit breakers employ sulfur hexafluoride gas for arc suppression, providing excellent dielectric strength and arc quenching capabilities, ideal for high voltage and extra-high voltage systems. Both technologies play critical roles in electrical power distribution, with vacuum breakers favored for compactness and environmental benefits, while SF6 breakers are preferred for their superior insulation and reliability in demanding conditions.

Vacuum Circuit Breaker: Operating Principle

Vacuum circuit breakers operate by interrupting the current flow within a vacuum-sealed chamber, where the arc is extinguished quickly due to the high dielectric strength of the vacuum. The absence of gas or other insulating mediums results in minimal arc energy and rapid recovery of dielectric strength, ensuring efficient interruption and reduced contact erosion. This operating principle makes vacuum circuit breakers highly reliable, low-maintenance, and suitable for medium-voltage applications.

SF6 Circuit Breaker: Operating Principle

SF6 circuit breakers operate by utilizing sulfur hexafluoride gas as an arc quenching medium, which effectively extinguishes the arc formed when the circuit breaker contacts open. The high dielectric strength and thermal stability of SF6 gas enable rapid arc interruption and excellent insulation properties, ensuring reliable performance in high-voltage systems. This operating principle allows SF6 circuit breakers to handle higher power ratings with minimal maintenance compared to vacuum circuit breakers.

Key Differences Between Vacuum and SF6 Circuit Breakers

Vacuum circuit breakers use vacuum as the arc quenching medium, providing rapid arc extinction and minimal contact wear, while SF6 circuit breakers utilize sulfur hexafluoride gas known for excellent dielectric strength and arc interruption capabilities. Vacuum breakers offer lower maintenance and environmental impact due to the absence of greenhouse gases, whereas SF6 breakers require gas handling systems and management to prevent SF6 leaks. The key differences include operational mechanisms, insulating mediums, maintenance needs, and environmental considerations, making vacuum breakers ideal for medium voltage applications and SF6 breakers suitable for high voltage systems.

Electrical Insulation Properties Comparison

Vacuum circuit breakers provide excellent electrical insulation by maintaining an extremely high dielectric strength within the vacuum interrupter, effectively preventing arc re-ignition and ensuring rapid arc extinction. SF6 circuit breakers use sulfur hexafluoride gas, which has superior dielectric strength and excellent arc-quenching capabilities compared to air or nitrogen, making it highly effective in high-voltage applications. While SF6 offers higher insulation properties at elevated voltages, vacuum circuit breakers are preferred for medium voltage due to their compact design and minimal environmental impact.

Applications and Usage Scenarios

Vacuum circuit breakers are widely used in medium-voltage applications such as industrial plants, commercial buildings, and utility distribution systems due to their low maintenance requirements and environmental safety. SF6 circuit breakers are preferred in high-voltage and extra-high-voltage substations and power transmission networks because of their superior arc-quenching capability and compact design. In scenarios demanding reliable interruption of large currents and minimal switching time, SF6 breakers offer enhanced performance, while vacuum breakers excel in settings requiring longevity and lower operating costs.

Environmental Impact and Safety Concerns

Vacuum circuit breakers (VCBs) have a significantly lower environmental impact than SF6 circuit breakers due to the absence of sulfur hexafluoride gas, a potent greenhouse gas with a global warming potential (GWP) approximately 23,500 times that of CO2. VCBs eliminate risks associated with SF6 gas leakage, which poses long-term environmental hazards and requires careful handling and recycling protocols. From a safety perspective, VCBs reduce the risk of toxic gas exposure and pressure build-up, enhancing operational safety and minimizing environmental contamination.

Maintenance and Lifespan Considerations

Vacuum circuit breakers require minimal maintenance due to their sealed vacuum interrupter, which prevents contact erosion and contamination, resulting in longer operational life and reduced servicing frequency compared to SF6 circuit breakers. SF6 circuit breakers, while offering excellent insulation and arc-quenching properties, demand regular maintenance to monitor and prevent gas leakage, ensuring optimal dielectric performance and environmental safety. The lifespan of vacuum circuit breakers generally surpasses SF6 types, primarily because they avoid gas handling complexities and potential SF6 decompositions that can degrade breaker components over time.

Cost Analysis and Economic Factors

Vacuum circuit breakers typically exhibit lower initial capital costs and reduced maintenance expenses compared to SF6 circuit breakers due to their simpler design and absence of gas handling requirements. SF6 circuit breakers incur higher operational costs related to gas procurement, handling, and environmental compliance, impacting long-term economic viability. Evaluating total cost of ownership, vacuum circuit breakers provide more cost-effective solutions for medium-voltage applications, while SF6 remains preferred for high-voltage systems despite elevated expenses.

Selection Guidelines for Optimal Performance

Vacuum circuit breakers offer superior performance in medium-voltage applications due to their fast arc extinguishing and minimal maintenance requirements, making them ideal for environments where compact design and safety are priorities. SF6 circuit breakers excel in high-voltage applications, providing excellent dielectric strength and arc-quenching capabilities, but require careful handling of SF6 gas to prevent environmental impact. Selection between these breakers depends on application voltage level, maintenance capabilities, environmental impact considerations, and operational reliability requirements.

Arc Quenching Medium

Vacuum circuit breakers utilize a vacuum as the arc quenching medium to extinguish arcs quickly and with minimal contact erosion, while SF6 circuit breakers use sulfur hexafluoride gas that offers excellent dielectric strength and arc suppression properties for effective arc quenching.

Dielectric Strength

Vacuum circuit breakers offer high dielectric strength through vacuum insulation that rapidly extinguishes arcs, while SF6 circuit breakers utilize sulfur hexafluoride gas with superior dielectric properties to insulate and quench electrical arcs more effectively under high-voltage conditions.

Interruption Capacity

Vacuum circuit breakers offer high interruption capacity for medium voltage applications with rapid arc extinction, while SF6 circuit breakers provide superior interruption capacity for high voltage and extra-high voltage systems due to the excellent dielectric properties of SF6 gas.

Contact Erosion

Vacuum circuit breakers exhibit significantly lower contact erosion compared to SF6 circuit breakers, resulting in longer contact life and reduced maintenance requirements.

Arc Extinction Chamber

Vacuum circuit breakers extinguish arcs within a high vacuum chamber by rapidly deionizing the arc plasma, whereas SF6 circuit breakers utilize sulfur hexafluoride gas in a pressurized chamber to quench arcs through gas insulation and cooling properties.

Operating Mechanism

Vacuum circuit breakers interrupt electrical arcs by creating a vacuum environment to extinguish the arc quickly, while SF6 circuit breakers use sulfur hexafluoride gas to quench arcs by cooling and absorbing electrical energy.

Gas Insulated Switchgear (GIS)

Vacuum circuit breakers offer faster arc quenching and lower maintenance in Gas Insulated Switchgear (GIS) compared to SF6 circuit breakers, which provide superior dielectric strength and greenhouse gas challenges.

Environmental Impact

Vacuum circuit breakers have a significantly lower environmental impact than SF6 circuit breakers because they do not use sulfur hexafluoride, a potent greenhouse gas with a global warming potential approximately 23,500 times greater than CO2.

Maintenance Frequency

Vacuum circuit breakers require less frequent maintenance, typically every 3-5 years, while SF6 circuit breakers demand more frequent inspections and maintenance, often annually, due to gas monitoring and handling requirements.

Pure Vacuum Integrity

Vacuum circuit breakers maintain pure vacuum integrity within their interrupters, ensuring superior dielectric strength and minimal gas contamination compared to SF6 circuit breakers that rely on sulfur hexafluoride gas insulation.

vacuum circuit breaker vs SF6 circuit breaker Infographic

njnir.com

njnir.com