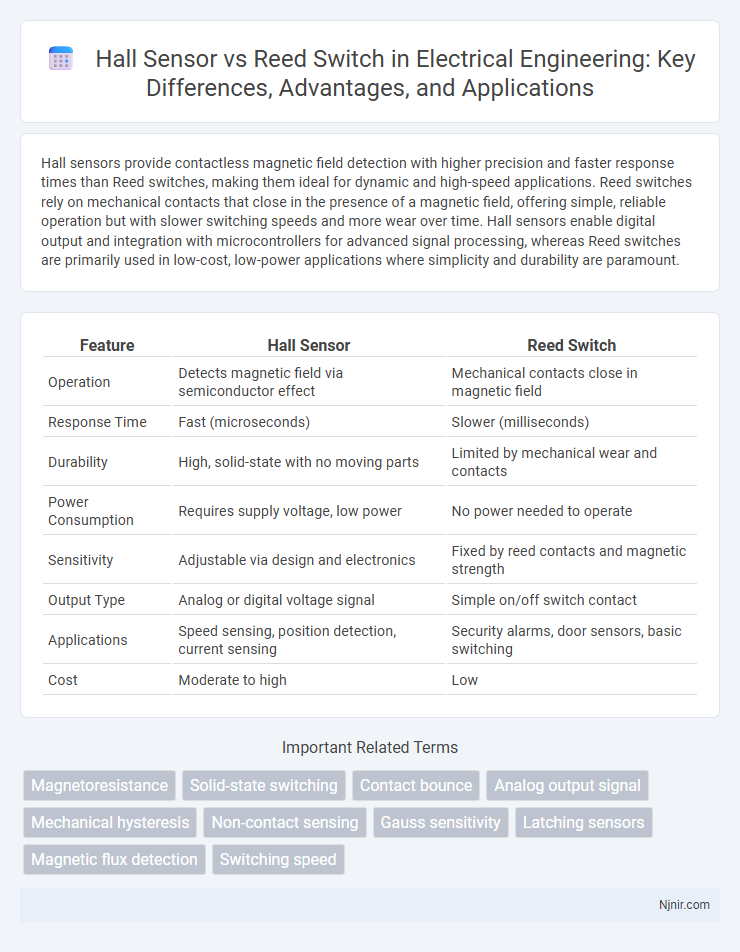

Hall sensors provide contactless magnetic field detection with higher precision and faster response times than Reed switches, making them ideal for dynamic and high-speed applications. Reed switches rely on mechanical contacts that close in the presence of a magnetic field, offering simple, reliable operation but with slower switching speeds and more wear over time. Hall sensors enable digital output and integration with microcontrollers for advanced signal processing, whereas Reed switches are primarily used in low-cost, low-power applications where simplicity and durability are paramount.

Table of Comparison

| Feature | Hall Sensor | Reed Switch |

|---|---|---|

| Operation | Detects magnetic field via semiconductor effect | Mechanical contacts close in magnetic field |

| Response Time | Fast (microseconds) | Slower (milliseconds) |

| Durability | High, solid-state with no moving parts | Limited by mechanical wear and contacts |

| Power Consumption | Requires supply voltage, low power | No power needed to operate |

| Sensitivity | Adjustable via design and electronics | Fixed by reed contacts and magnetic strength |

| Output Type | Analog or digital voltage signal | Simple on/off switch contact |

| Applications | Speed sensing, position detection, current sensing | Security alarms, door sensors, basic switching |

| Cost | Moderate to high | Low |

Introduction to Hall Sensors and Reed Switches

Hall sensors detect magnetic fields using the Hall effect, providing contactless, reliable, and fast response suitable for precise position and speed sensing. Reed switches consist of two ferromagnetic blades sealed in a glass tube that close when exposed to a magnetic field, offering simple, low-cost switching with mechanical contact. Hall sensors are widely applied in automotive and industrial systems, while reed switches excel in low-power, alarm, and proximity detection applications.

Working Principles: Hall Sensor vs Reed Switch

Hall sensors operate based on the Hall effect, detecting magnetic fields by measuring the voltage generated perpendicular to the current flow in a semiconductor material. Reed switches function through the mechanical movement of ferromagnetic contacts that close or open a circuit when exposed to an external magnetic field. The non-contact nature of Hall sensors provides higher durability and faster response compared to the physical contact mechanism of reed switches.

Key Components and Construction

The Hall sensor relies on a thin semiconductor element that detects magnetic fields through the Hall effect, incorporating a chip, magnet, and integrated circuit for signal processing. In contrast, the Reed switch consists of two ferromagnetic blades sealed within a glass envelope that closes or opens in response to magnetic forces. The Hall sensor's solid-state design ensures greater durability and faster response, while the Reed switch offers simplicity and cost-effectiveness in its mechanical construction.

Sensitivity and Precision Comparison

Hall sensors offer higher sensitivity and precision compared to reed switches, detecting magnetic fields with greater accuracy due to their semiconductor-based technology. Reed switches rely on mechanical contacts, resulting in lower sensitivity and prone to contact bounce, which reduces measurement precision. Hall sensors provide consistent, repeatable readings in varying environmental conditions, making them ideal for applications requiring fine magnetic detection.

Response Time and Performance

Hall sensors offer faster response times than reed switches, typically in the microsecond range compared to the millisecond range for reed switches. The solid-state design of Hall sensors provides higher reliability, greater durability, and resistance to mechanical wear, resulting in more consistent performance over time. Reed switches, while cost-effective and simple, suffer from slower switching speeds and potential contact bounce, limiting their use in high-speed or high-frequency applications.

Power Consumption Differences

Hall sensors typically consume more power than reed switches due to their active electronic components requiring a continuous current supply, often in the range of milliamps. Reed switches operate passively without power until activated by a magnetic field, resulting in virtually zero power consumption in standby mode. These differences make reed switches more suitable for low-power or battery-operated devices where power efficiency is critical.

Durability and Environmental Resistance

Hall sensors offer superior durability compared to reed switches due to their solid-state construction, which eliminates mechanical wear and tear. Reed switches are more susceptible to contact degradation and mechanical failure under repeated cycling or vibration. Hall sensors also provide enhanced environmental resistance, functioning reliably in harsh conditions such as moisture, dust, and extreme temperatures, whereas reed switches may suffer from corrosion and reduced lifespan in such environments.

Common Applications in Electrical Engineering

Hall sensors are widely used in brushless DC motor control, current sensing, and proximity detection due to their contactless operation and high reliability. Reed switches find common applications in security systems for door and window sensors, as well as in position and speed sensing in mechanical devices where simplicity and low power consumption are crucial. Both components are integral in automation and control systems but are chosen based on specific environmental and performance requirements.

Integration and Circuit Design Considerations

Hall sensors offer seamless integration in compact electronic circuits due to their solid-state design and require minimal external components, enabling reliable and noise-resistant magnetic field detection. Reed switches, being electromechanical devices, need careful consideration of contact bounce and limited switching speed, which can complicate circuit design and increase the need for debounce circuitry. The choice between Hall sensors and Reed switches impacts board space, power consumption, and signal conditioning requirements in system-level integration.

Cost Analysis and Selection Criteria

Hall sensors generally have a higher initial cost than reed switches due to their semiconductor components and integrated circuitry. Reed switches offer lower upfront expenses and simpler installation but may incur higher long-term maintenance costs due to mechanical wear and susceptibility to contact degradation. Selection criteria should consider total cost of ownership, operating environment, switching frequency, and required durability, where Hall sensors excel in high-reliability and high-speed applications despite higher initial investment.

Magnetoresistance

Hall sensors provide precise, contactless magnetic field measurements by detecting changes in magnetoresistance, whereas reed switches operate mechanically without utilizing magnetoresistive principles.

Solid-state switching

Hall sensors offer solid-state switching with higher durability and faster response times compared to mechanical Reed switches, making them ideal for applications requiring stable, contactless magnetic detection.

Contact bounce

Hall sensors eliminate contact bounce by using solid-state magnetic sensing, whereas reed switches experience contact bounce due to their mechanical contacts physically closing and opening.

Analog output signal

Hall sensors provide a continuous analog output voltage proportional to the magnetic field strength, whereas reed switches produce a binary on/off signal without analog variation.

Mechanical hysteresis

Hall sensors exhibit minimal mechanical hysteresis due to their solid-state design, whereas reed switches demonstrate significant mechanical hysteresis caused by physical contact switching.

Non-contact sensing

Hall sensors provide precise, reliable non-contact sensing by detecting magnetic fields through semiconductor elements, while reed switches operate mechanically by closing contacts in response to magnetic fields, resulting in slower response and limited durability.

Gauss sensitivity

Hall sensors typically offer higher Gauss sensitivity than reed switches, enabling more precise magnetic field detection in low-strength environments.

Latching sensors

Latching Hall sensors provide faster response times, higher durability, and contactless operation compared to Reed switches, making them ideal for reliable magnetic position sensing in industrial applications.

Magnetic flux detection

Hall sensors detect magnetic flux through semiconductor elements generating voltage proportional to the magnetic field strength, while reed switches mechanically close contacts in response to magnetic flux, offering faster response but less durability in high-frequency magnetic detection.

Switching speed

Hall sensors offer switching speeds in the microsecond range, significantly faster than reed switches which typically switch in the millisecond range.

Hall sensor vs Reed switch Infographic

njnir.com

njnir.com