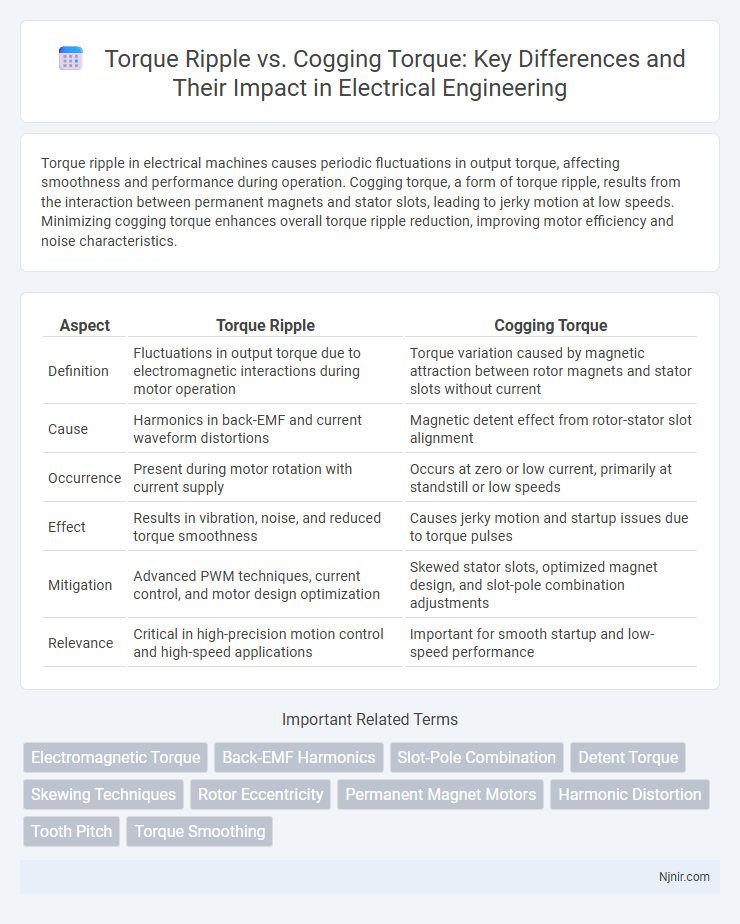

Torque ripple in electrical machines causes periodic fluctuations in output torque, affecting smoothness and performance during operation. Cogging torque, a form of torque ripple, results from the interaction between permanent magnets and stator slots, leading to jerky motion at low speeds. Minimizing cogging torque enhances overall torque ripple reduction, improving motor efficiency and noise characteristics.

Table of Comparison

| Aspect | Torque Ripple | Cogging Torque |

|---|---|---|

| Definition | Fluctuations in output torque due to electromagnetic interactions during motor operation | Torque variation caused by magnetic attraction between rotor magnets and stator slots without current |

| Cause | Harmonics in back-EMF and current waveform distortions | Magnetic detent effect from rotor-stator slot alignment |

| Occurrence | Present during motor rotation with current supply | Occurs at zero or low current, primarily at standstill or low speeds |

| Effect | Results in vibration, noise, and reduced torque smoothness | Causes jerky motion and startup issues due to torque pulses |

| Mitigation | Advanced PWM techniques, current control, and motor design optimization | Skewed stator slots, optimized magnet design, and slot-pole combination adjustments |

| Relevance | Critical in high-precision motion control and high-speed applications | Important for smooth startup and low-speed performance |

Introduction to Torque Ripple and Cogging Torque

Torque ripple and cogging torque are critical factors affecting the performance of electric motors, influencing smoothness and efficiency. Torque ripple refers to the periodic variation in torque output caused by electromagnetic interactions during rotation, leading to vibrations and noise. Cogging torque arises from the magnetic attraction between the rotor's permanent magnets and stator slots, creating torque fluctuations even without current flow.

Fundamental Differences Between Torque Ripple and Cogging Torque

Torque ripple refers to the periodic fluctuation in motor torque caused by the interaction between the stator magnetic field and the rotor magnetic field during rotation, resulting in torque variations even under constant speed conditions. Cogging torque, a specific form of torque ripple, arises from the alignment and misalignment of rotor permanent magnets with stator teeth, producing torque variations at specific rotor positions independent of current flow. The fundamental difference lies in torque ripple encompassing all torque disturbances including those from current harmonics and magnetic saturation, whereas cogging torque is purely a position-dependent, current-free phenomenon inherent to the motor's physical construction.

Causes and Sources of Torque Ripple

Torque ripple primarily originates from imperfections in motor design such as slotting effects, magnetic saturation, and uneven air gaps, causing periodic fluctuations in the output torque. Cogging torque, a subset of torque ripple, arises specifically from the interaction between the permanent magnets and stator slots, producing a cog-like sensation during rotation. Understanding these causes is crucial for optimizing brushless DC motors and minimizing mechanical vibrations and noise.

Origins and Mechanisms of Cogging Torque

Cogging torque originates from the magnetic interaction between the permanent magnets of a rotor and the stator slots in brushless DC motors, causing position-dependent torque pulsations. Its mechanism involves the tendency of the rotor to align with the stator teeth due to variations in magnetic reluctance, generating torque ripple even at zero current. Unlike torque ripple, which includes effects from current commutation and winding harmonics, cogging torque is purely a result of the motor's geometric and magnetic design.

Impact on Motor Performance and Efficiency

Torque ripple causes fluctuations in motor output torque, leading to vibration, noise, and reduced precision in applications requiring smooth motion. Cogging torque results from the interaction between permanent magnets and stator slots, creating a torque ripple at zero current that hinders low-speed performance and increases energy loss. Both phenomena degrade motor efficiency by increasing mechanical stress and electrical power consumption, negatively affecting overall operational stability and energy utilization.

Measurement Techniques for Torque Ripple and Cogging Torque

Torque ripple and cogging torque measurement techniques involve precise instrumentation such as torque sensors and rotary encoders to capture torque fluctuations under varying load and speed conditions. Fourier analysis and fast Fourier transform (FFT) methods accurately quantify torque ripple by identifying harmonic components in the torque signal during motor operation. Cogging torque is typically measured using detent torque tests where the rotor is slowly turned at zero current to isolate the magnetic effect without commutation interference, enabling detailed characterization of torque variation caused by permanent magnet and stator slot interactions.

Effects on Noise, Vibration, and Smoothness

Torque ripple causes periodic fluctuations in the motor's output torque, directly increasing noise and vibration levels, which degrade smoothness in mechanical systems. Cogging torque results from the interaction between permanent magnets and stator slots, producing distinct jerks that contribute to discrete vibration pulses and audible noise, reducing operational smoothness. Minimizing both torque ripple and cogging torque is essential for enhancing motor performance, especially in precision applications requiring quiet and smooth motion.

Reduction Strategies for Torque Ripple

Torque ripple and cogging torque are primary sources of vibration and noise in electric motors, affecting efficiency and performance. Reduction strategies for torque ripple focus on optimizing motor design by implementing skewed stator slots, employing fractional slot winding, and using advanced control algorithms such as field-oriented control (FOC) to smooth torque output. Material selection and rotor geometry adjustments also contribute significantly to minimizing torque ripple, enhancing overall motor reliability and lifespan.

Mitigation Methods for Cogging Torque

Cogging torque, caused by the interaction between permanent magnets and stator slots, can lead to torque ripple and vibration in permanent magnet synchronous motors (PMSMs). Mitigation methods for cogging torque include optimizing the rotor slot geometry, skewing the stator slots or rotor magnets, using fractional slot windings, and employing magnet shaping techniques to reduce magnetic detent effects. Advanced control strategies such as field-oriented control (FOC) and direct torque control (DTC) further minimize the impact of cogging torque on motor performance.

Practical Applications and Design Considerations

Torque ripple and cogging torque significantly impact the performance of electric motors in precision applications such as robotics and automotive systems. Minimizing torque ripple enhances smooth motor operation by reducing vibrations and noise, while addressing cogging torque is critical for improving low-speed torque uniformity and positioning accuracy, often achieved through rotor and stator slot design optimization. Practical design considerations involve selecting appropriate magnetic materials, optimizing slot/pole combinations, and employing skewing techniques to balance these torques for efficient, reliable motor performance.

Electromagnetic Torque

Torque ripple is the periodic variation in electromagnetic torque caused by stator-rotor slot interactions, whereas cogging torque is the torque due to the alignment of permanent magnet poles with stator slots in a permanent magnet motor, both critically affecting smooth electromagnetic torque output.

Back-EMF Harmonics

Torque ripple primarily arises from Back-EMF harmonics causing periodic variations in electromagnetic torque, whereas cogging torque results from the geometric interaction between permanent magnets and stator slots, influencing torque pulsations independent of back-EMF harmonics.

Slot-Pole Combination

Slot-pole combination significantly influences torque ripple and cogging torque in electric motors, with optimized designs minimizing torque ripple for smoother operation and reducing cogging torque to enhance performance in slotless or slotted permanent magnet motors.

Detent Torque

Detent torque, a specific type of cogging torque caused by magnetic attraction between rotor and stator teeth, significantly influences torque ripple in permanent magnet motors by creating periodic torque variations during rotation.

Skewing Techniques

Skewing techniques effectively reduce torque ripple and cogging torque in electric motors by altering the rotor or stator geometry to minimize magnetic interaction variations.

Rotor Eccentricity

Rotor eccentricity significantly amplifies torque ripple more than cogging torque in electric motors by causing uneven air gap variations that disrupt magnetic flux distribution.

Permanent Magnet Motors

Torque ripple in permanent magnet motors results from the interaction between stator and rotor magnetic fields producing periodic torque variations, while cogging torque arises specifically from the magnetic attraction between permanent magnets and stator slots causing position-dependent torque disturbances.

Harmonic Distortion

Torque ripple primarily results from harmonic distortion in the motor's back-EMF waveform, while cogging torque arises from the interaction of permanent magnet flux with stator slot edges causing periodic torque variations.

Tooth Pitch

Torque ripple primarily arises from variations in tooth pitch leading to uneven magnetic forces, whereas cogging torque results from the interaction between permanent magnets and stator teeth at fixed tooth pitch intervals causing periodic torque fluctuations.

Torque Smoothing

Torque ripple reduction techniques effectively minimize fluctuations caused by cogging torque, enhancing overall torque smoothing in electric motor performance.

Torque Ripple vs Cogging Torque Infographic

njnir.com

njnir.com