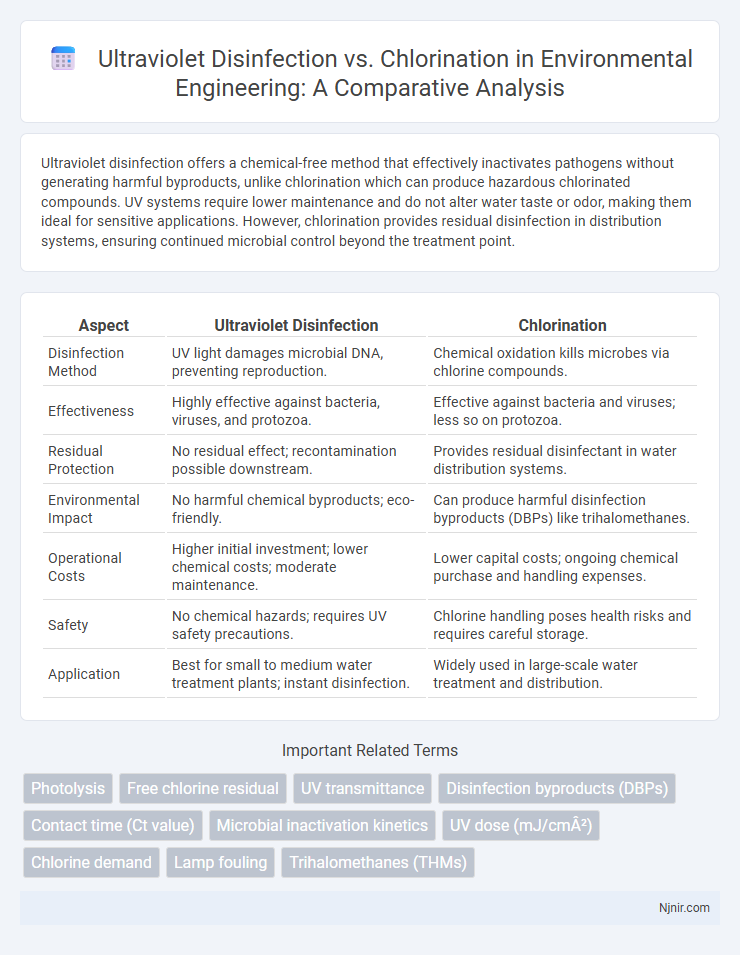

Ultraviolet disinfection offers a chemical-free method that effectively inactivates pathogens without generating harmful byproducts, unlike chlorination which can produce hazardous chlorinated compounds. UV systems require lower maintenance and do not alter water taste or odor, making them ideal for sensitive applications. However, chlorination provides residual disinfection in distribution systems, ensuring continued microbial control beyond the treatment point.

Table of Comparison

| Aspect | Ultraviolet Disinfection | Chlorination |

|---|---|---|

| Disinfection Method | UV light damages microbial DNA, preventing reproduction. | Chemical oxidation kills microbes via chlorine compounds. |

| Effectiveness | Highly effective against bacteria, viruses, and protozoa. | Effective against bacteria and viruses; less so on protozoa. |

| Residual Protection | No residual effect; recontamination possible downstream. | Provides residual disinfectant in water distribution systems. |

| Environmental Impact | No harmful chemical byproducts; eco-friendly. | Can produce harmful disinfection byproducts (DBPs) like trihalomethanes. |

| Operational Costs | Higher initial investment; lower chemical costs; moderate maintenance. | Lower capital costs; ongoing chemical purchase and handling expenses. |

| Safety | No chemical hazards; requires UV safety precautions. | Chlorine handling poses health risks and requires careful storage. |

| Application | Best for small to medium water treatment plants; instant disinfection. | Widely used in large-scale water treatment and distribution. |

Introduction to Water Disinfection Methods

Ultraviolet disinfection uses UV-C light to inactivate microorganisms by damaging their DNA, providing a chemical-free method without producing harmful byproducts. Chlorination involves adding chlorine compounds to water, effectively killing bacteria and viruses while offering residual protection against recontamination in distribution systems. Both methods are widely applied in drinking water treatment, with UV favored for its eco-friendly profile and chlorination preferred for maintaining long-lasting disinfection.

Principles of Ultraviolet Disinfection

Ultraviolet disinfection inactivates microorganisms by exposing them to UV-C light at wavelengths around 254 nm, which penetrates their cell walls and disrupts DNA and RNA, preventing replication and infection. Unlike chlorination, which relies on chemical oxidation to kill pathogens, UV disinfection offers a chemical-free method that leaves no residual taste or odor in treated water. The efficiency of UV systems depends on factors such as UV dose, exposure time, water turbidity, and lamp intensity.

Fundamentals of Chlorination

Chlorination involves adding chlorine or chlorine compounds to water, effectively killing bacteria, viruses, and protozoa through oxidation and disruption of microbial cell walls. This method provides a residual disinfectant effect, maintaining water safety throughout distribution systems by preventing recontamination. Its effectiveness depends on factors such as chlorine concentration, contact time, pH, and temperature.

Comparative Effectiveness Against Pathogens

Ultraviolet disinfection inactivates a broad spectrum of pathogens, including bacteria, viruses, and protozoa, by disrupting their DNA and RNA, offering rapid and chemical-free treatment. Chlorination provides persistent residual disinfection, effectively targeting bacteria and viruses but showing reduced efficacy against chlorine-resistant protozoan cysts like Cryptosporidium and Giardia. Both methods are often combined to optimize pathogen elimination and maintain water safety during distribution.

Chemical Byproducts and Environmental Impact

Ultraviolet disinfection produces no harmful chemical byproducts, making it an environmentally friendly option that avoids issues like trihalomethanes and haloacetic acids associated with chlorination. Chlorination, while effective, generates disinfection byproducts (DBPs) that can pose health risks and contribute to water pollution. Ultraviolet systems also reduce the need for chemical storage and transportation, further lowering their environmental footprint compared to chlorination processes.

Operational and Maintenance Requirements

Ultraviolet disinfection systems require regular cleaning of UV lamps and sleeves to maintain effective irradiance, with lamp replacement typically needed every 9,000 to 12,000 hours of operation. Chlorination demands continuous monitoring of chlorine residual levels and frequent adjustment of chemical dosing equipment to ensure safe disinfection while minimizing harmful byproducts. UV systems generally have lower chemical handling risks and produce no disinfection byproducts, whereas chlorination involves managing storage and handling of potentially hazardous chemicals and generating disinfection byproducts such as trihalomethanes.

Cost Analysis and Economic Considerations

Ultraviolet disinfection typically incurs higher upfront capital costs due to specialized lamp systems and maintenance requirements, but offers lower operational expenses by avoiding chemical purchases and residual disposal. Chlorination presents lower initial investment but ongoing costs for chemical procurement, storage, handling, and potential byproduct management raise long-term expenses. Evaluating life cycle costs, including energy consumption and regulatory compliance, is essential for determining the most cost-effective water treatment method.

Health and Safety Implications

Ultraviolet disinfection effectively inactivates a broad spectrum of pathogens without producing harmful chemical byproducts, significantly reducing risks of exposure to toxic substances compared to chlorination. Chlorination, while widely used, can generate disinfection byproducts such as trihalomethanes and haloacetic acids, which are linked to respiratory issues and potential carcinogenic effects. UV systems require careful maintenance to ensure consistent microbial inactivation, but they inherently avoid chlorine-related occupational hazards, making them a safer choice for both consumers and water treatment personnel.

Applicability in Municipal and Industrial Settings

Ultraviolet disinfection offers rapid microbial inactivation without chemical residues, making it ideal for municipal water treatment plants requiring high water quality and low environmental impact. Chlorination provides long-lasting residual disinfectant in distribution systems, essential for preventing microbial regrowth in both municipal and industrial water supplies. Industrial applications favor chlorination for its cost-effectiveness and ability to control biofilm in cooling towers, whereas UV systems are preferred in food and pharmaceutical industries for chemical-free sterilization.

Future Trends in Water Disinfection Technology

Ultraviolet disinfection offers a chemical-free approach to water treatment, reducing the formation of harmful disinfection byproducts prevalent in chlorination processes. Innovations in UV LED technology are improving energy efficiency and enabling more compact, scalable systems suitable for diverse applications from municipal to residential use. Advanced hybrid systems combining UV and chlorination are emerging to enhance pathogen inactivation while minimizing chemical usage and maintaining residual protection in distribution networks.

Photolysis

Ultraviolet disinfection leverages photolysis to break down contaminants and pathogens by disrupting their molecular bonds, offering a chemical-free alternative to chlorination.

Free chlorine residual

Ultraviolet disinfection effectively inactivates pathogens without producing a free chlorine residual, whereas chlorination maintains a persistent free chlorine residual that provides ongoing microbial protection in water systems.

UV transmittance

Ultraviolet disinfection efficacy depends on high UV transmittance of water, whereas chlorination effectiveness is less influenced by water clarity.

Disinfection byproducts (DBPs)

Ultraviolet disinfection effectively eliminates pathogens without producing harmful disinfection byproducts (DBPs), unlike chlorination which generates various toxic DBPs such as trihalomethanes (THMs) and haloacetic acids (HAAs) linked to health risks.

Contact time (Ct value)

Ultraviolet disinfection typically requires significantly lower contact time (Ct values) compared to chlorination to achieve equivalent pathogen inactivation levels.

Microbial inactivation kinetics

Ultraviolet disinfection exhibits rapid microbial inactivation kinetics by damaging nucleic acids and preventing replication, while chlorination relies on oxidative stress inducing slower microbial inactivation with residual disinfection capacity.

UV dose (mJ/cm²)

Ultraviolet disinfection requires an optimized UV dose typically ranging from 30 to 100 mJ/cm2 to effectively inactivate pathogens, whereas chlorination depends on concentration and contact time rather than UV dose for microbial control.

Chlorine demand

Chlorine demand in water treatment varies based on factors like organic matter and microbial load, often requiring higher doses compared to ultraviolet disinfection, which relies on light intensity and exposure time without chemical residuals.

Lamp fouling

Ultraviolet disinfection efficiency declines significantly due to lamp fouling, whereas chlorination effectiveness remains largely unaffected by such surface deposits.

Trihalomethanes (THMs)

Ultraviolet disinfection eliminates pathogens without generating harmful Trihalomethanes (THMs) that commonly result from chlorination in water treatment.

ultraviolet disinfection vs chlorination Infographic

njnir.com

njnir.com