Dynamic compaction involves dropping heavy weights to densify soil layers, effectively increasing soil bearing capacity and reducing settlement in granular and mixed soil profiles. Vibroflotation uses vibrating probes to rearrange soil particles, enhancing density primarily in cohesionless soils and improving stability for foundation support. Both methods improve ground conditions, but dynamic compaction is better suited for deeper compaction, while vibroflotation is more efficient for treating loose granular soils at shallow depths.

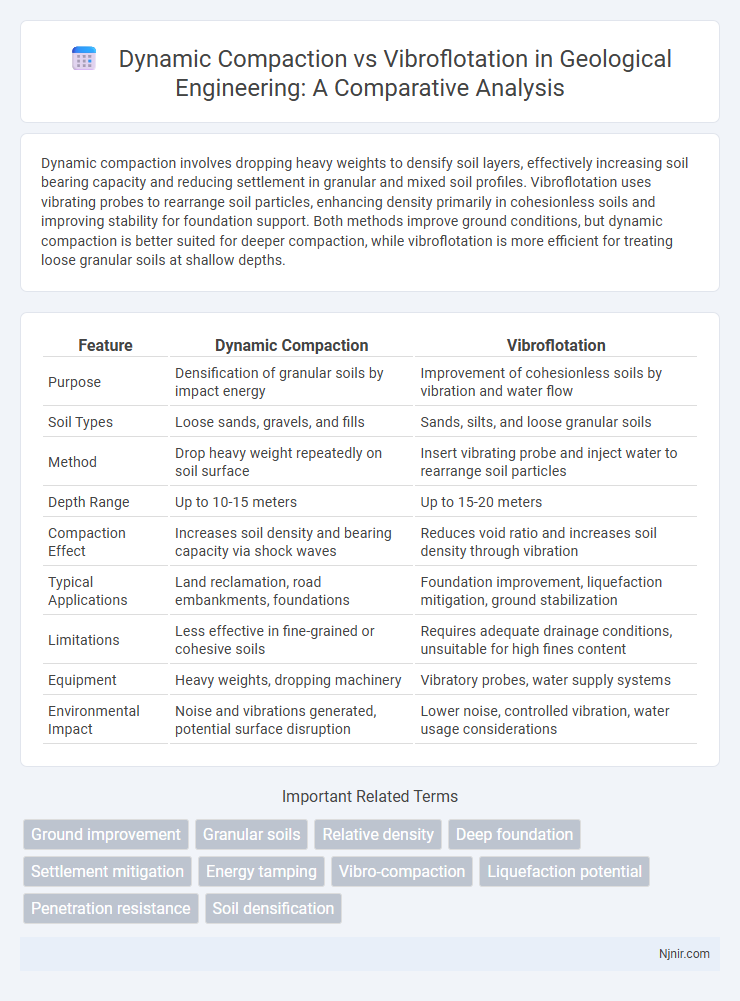

Table of Comparison

| Feature | Dynamic Compaction | Vibroflotation |

|---|---|---|

| Purpose | Densification of granular soils by impact energy | Improvement of cohesionless soils by vibration and water flow |

| Soil Types | Loose sands, gravels, and fills | Sands, silts, and loose granular soils |

| Method | Drop heavy weight repeatedly on soil surface | Insert vibrating probe and inject water to rearrange soil particles |

| Depth Range | Up to 10-15 meters | Up to 15-20 meters |

| Compaction Effect | Increases soil density and bearing capacity via shock waves | Reduces void ratio and increases soil density through vibration |

| Typical Applications | Land reclamation, road embankments, foundations | Foundation improvement, liquefaction mitigation, ground stabilization |

| Limitations | Less effective in fine-grained or cohesive soils | Requires adequate drainage conditions, unsuitable for high fines content |

| Equipment | Heavy weights, dropping machinery | Vibratory probes, water supply systems |

| Environmental Impact | Noise and vibrations generated, potential surface disruption | Lower noise, controlled vibration, water usage considerations |

Introduction to Ground Improvement Techniques

Dynamic compaction uses heavy weights dropped from heights to densify loose granular soils by imparting energy that rearranges particles, improving load-bearing capacity and reducing settlement. Vibroflotation employs a vibrating probe to fluidize and reorient granular soils, enhancing density and stability primarily in cohesionless soils like sands and gravels. Both techniques are essential ground improvement methods targeting different soil conditions to optimize foundation performance and construction safety.

Principles of Dynamic Compaction

Dynamic compaction improves soil density by repeatedly dropping heavy weights from significant heights, generating shock waves that rearrange soil particles into a denser configuration, which enhances load-bearing capacity and reduces settlement. This method is effective in granular soils and loose fill by inducing plastic deformation and pore water dissipation through impact energy transfer. In contrast to vibroflotation, which uses vibratory probes to rearrange soil particles, dynamic compaction relies on impact energy to achieve compaction at greater depths and in a wider range of soil types.

Principles of Vibroflotation

Vibroflotation uses a vibrating probe to rearrange granular soil particles, increasing density and improving load-bearing capacity, primarily in cohesionless soils such as sand or gravel. This method relies on vibration-induced liquefaction to allow soil particles to settle into a denser configuration, reducing void ratios and increasing strength. Dynamic compaction, by contrast, employs heavy weights dropped from heights to densify soils through impact energy, but is less effective for uniform compaction in cohesionless layers compared to vibroflotation.

Geological Conditions Suitable for Each Method

Dynamic compaction is most effective in granular soils such as loose sands and silty sands with a moderate to high moisture content, where deep densification can be achieved through heavy weight dropping. Vibroflotation is ideal for well-graded granular soils, including clean sands and gravels, particularly in uniform alluvial deposits with limited fines that allow for effective water displacement during vibration. Both methods are less suitable for cohesive soils like clay or those with high silt content, where soil structure and drainage characteristics impede energy transfer and densification efficiency.

Equipment and Machinery Used

Dynamic compaction utilizes heavy weights, typically ranging from 10 to 40 tons, dropped from heights of 10 to 30 meters using cranes or derricks to densify soil through impact energy. Vibroflotation employs vertical vibratory probes, powered by hydraulic or electric vibrators, that penetrate granular soils to rearrange particles and expel air and water, often accompanied by water jets to enhance penetration and densification. Equipment for dynamic compaction is generally bulky and stationary, while vibroflotation machinery is more mobile, allowing for precise control and application in irregular or confined spaces.

Comparative Compaction Depth and Effectiveness

Dynamic compaction typically achieves effective compaction at depths up to 15 meters, making it suitable for dense granular soils and reducing settlement potential in thicker soil layers. Vibroflotation, on the other hand, is effective primarily in sandy and granular soils up to depths of 10 to 12 meters, enhancing soil density through vibration that eliminates voids and improves drainage. The choice between dynamic compaction and vibroflotation depends on soil type and required compaction depth, with dynamic compaction offering deeper penetration and vibroflotation providing uniform densification in shallow to moderate depths.

Typical Applications in Civil Engineering Projects

Dynamic compaction is typically applied for improving load bearing capacity and reducing settlement in soft, granular soils under foundation slabs, embankments, and storage yards. Vibroflotation is widely used for densifying loose, cohesionless soils like sands and gravels beneath roadways, bridge abutments, and airport runways to enhance bearing capacity and mitigate liquefaction risk. Both techniques are essential in ground improvement strategies for infrastructure projects requiring increased soil stability and reduced settlement potential.

Environmental and Safety Considerations

Dynamic compaction generates significant ground vibrations and noise, which can disturb nearby communities and wildlife, necessitating careful monitoring and mitigation measures during operation. Vibroflotation, while quieter, poses risks related to the use of water and potential groundwater contamination if not managed properly, requiring strict control of water discharge and sediment management. Both methods demand adherence to safety protocols to prevent equipment hazards and ensure worker protection in the construction site environment.

Cost and Time Efficiency Analysis

Dynamic compaction typically incurs higher costs due to the use of heavy equipment and longer operational durations but offers faster ground improvement for deep, loose soil layers. Vibroflotation tends to be more cost-efficient for granular soils with moderate depth requirements, utilizing less power and offering quicker setup times. Time efficiency favors dynamic compaction when rapid densification is essential, whereas vibroflotation provides cost-saving advantages for projects with budget constraints and shallower treatment depths.

Selection Criteria: Dynamic Compaction vs Vibroflotation

Dynamic compaction and vibroflotation are selected based on soil type and project requirements, with dynamic compaction suited for loose, granular soils and thick fill layers, effectively densifying soils at greater depths. Vibroflotation is preferred for cohesionless, granular soils with relatively uniform particle size, offering rapid densification in near-surface layers. Cost, accessibility, and environmental impact also influence the decision, with dynamic compaction requiring heavy equipment and vibroflotation utilizing smaller, more precise vibratory probes.

Ground improvement

Dynamic compaction improves ground density through heavy weight dropping, while vibroflotation enhances soil stability by using vibration to rearrange granular particles.

Granular soils

Dynamic compaction densifies granular soils through high-energy impact dropping heavy weights, whereas vibroflotation utilizes vibratory probes to rearrange and compact soil particles by reducing voids.

Relative density

Dynamic compaction increases relative density by densifying coarse-grained soils through heavy tamping, while vibroflotation improves relative density by rearranging granular particles using vibratory probes in granular soils.

Deep foundation

Dynamic compaction densifies deep foundation soils through heavy weight dropping, while vibroflotation improves soil density by inserting and vibrating a probe to rearrange particles.

Settlement mitigation

Dynamic compaction reduces settlement by densifying soil layers through high-energy impact, while vibroflotation mitigates settlement by rearranging granular soils via vibration to increase density and stability.

Energy tamping

Dynamic compaction uses heavy weights dropped from heights to deliver high-impact energy for soil densification, whereas vibroflotation employs vibratory probes to transmit continuous vibrational energy for granular soil densification.

Vibro-compaction

Vibro-compaction significantly improves soil density by using a vibrating probe to rearrange granular soil particles, making it ideal for loose, cohesionless soils compared to dynamic compaction methods.

Liquefaction potential

Dynamic compaction reduces liquefaction potential by densifying granular soils through heavy-pounder impacts, while vibroflotation mitigates liquefaction risk by rearranging soil particles via high-frequency vibrations to increase soil density and stability.

Penetration resistance

Dynamic compaction achieves higher penetration resistance through heavy weight drop impacts, while vibroflotation improves penetration resistance by rearranging granular soils via vibratory energy.

Soil densification

Dynamic compaction increases soil densification by dropping heavy weights to compact granular soils, while vibroflotation uses vibration to rearrange and densify loose granular soils, particularly effective in sandy and gravelly substrates.

dynamic compaction vs vibroflotation Infographic

njnir.com

njnir.com