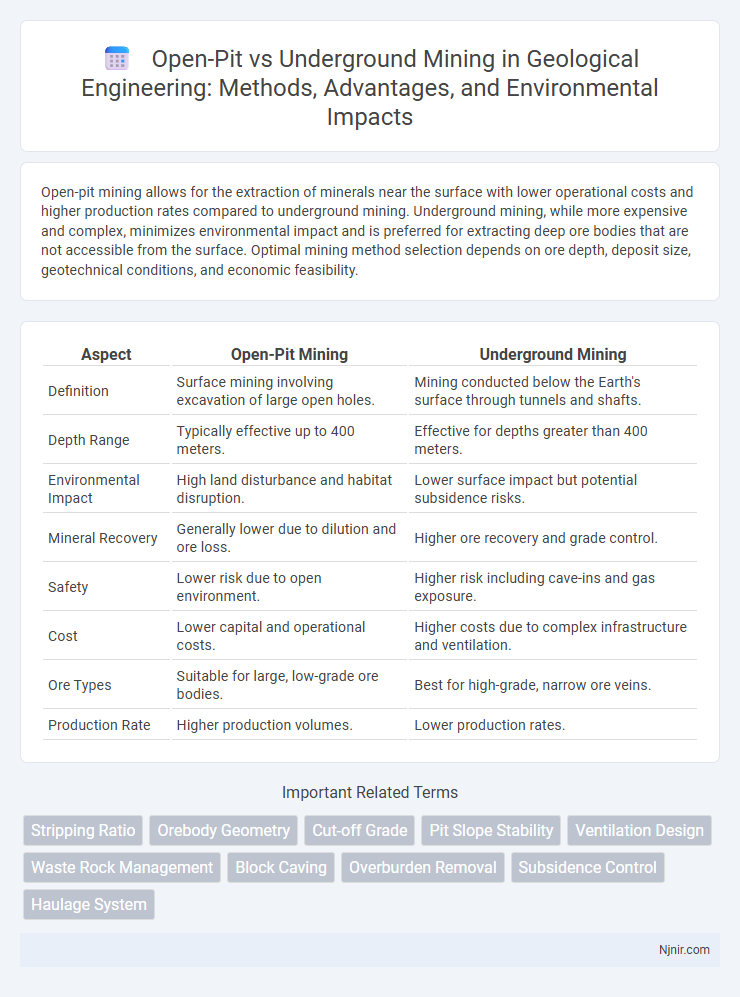

Open-pit mining allows for the extraction of minerals near the surface with lower operational costs and higher production rates compared to underground mining. Underground mining, while more expensive and complex, minimizes environmental impact and is preferred for extracting deep ore bodies that are not accessible from the surface. Optimal mining method selection depends on ore depth, deposit size, geotechnical conditions, and economic feasibility.

Table of Comparison

| Aspect | Open-Pit Mining | Underground Mining |

|---|---|---|

| Definition | Surface mining involving excavation of large open holes. | Mining conducted below the Earth's surface through tunnels and shafts. |

| Depth Range | Typically effective up to 400 meters. | Effective for depths greater than 400 meters. |

| Environmental Impact | High land disturbance and habitat disruption. | Lower surface impact but potential subsidence risks. |

| Mineral Recovery | Generally lower due to dilution and ore loss. | Higher ore recovery and grade control. |

| Safety | Lower risk due to open environment. | Higher risk including cave-ins and gas exposure. |

| Cost | Lower capital and operational costs. | Higher costs due to complex infrastructure and ventilation. |

| Ore Types | Suitable for large, low-grade ore bodies. | Best for high-grade, narrow ore veins. |

| Production Rate | Higher production volumes. | Lower production rates. |

Overview of Open-Pit and Underground Mining

Open-pit mining involves extracting minerals from a large surface excavation, making it suitable for shallow ore bodies with extensive horizontal reach. Underground mining targets deeper mineral deposits through tunnels and shafts, minimizing surface disruption and enabling access to concentrated ore veins. Both methods require specific techniques and equipment tailored to the ore depth, geology, and environmental impact considerations.

Geological Considerations for Method Selection

Open-pit mining is preferred when ore bodies are near the surface with favorable rock mass conditions and minimal overburden, allowing efficient extraction of large volumes. Underground mining is selected for deep, high-grade ores where surface disturbance must be minimized, requiring detailed geotechnical analysis to ensure stability of tunnels and stopes. Geological factors such as ore deposit shape, depth, rock strength, and groundwater presence critically influence the choice between open-pit and underground methods.

Economic Comparison between Open-Pit and Underground Mining

Open-pit mining generally offers lower operational costs due to higher extraction rates and easier access to ore bodies, resulting in greater economies of scale compared to underground mining. Underground mining entails higher expenses related to ventilation, safety, and labor intensity, which increase the overall cost per ton of extracted material. Resource grade, ore depth, and market prices critically influence the economic viability of choosing between open-pit and underground mining methods.

Environmental Impacts: Surface vs. Subsurface Extraction

Open-pit mining causes significant surface disruption, including habitat destruction, soil erosion, and large-scale waste rock deposits that can lead to water contamination. Underground mining minimizes surface footprint but poses subsurface risks such as groundwater depletion, subsidence, and the release of hazardous gases. Both methods require careful management to mitigate environmental impacts, with the choice often influenced by ore depth, mineral type, and local ecosystem sensitivity.

Safety Challenges in Open-Pit and Underground Operations

Open-pit mining presents safety challenges such as slope stability risks, exposure to weather conditions, and large-scale equipment accidents. Underground mining faces hazards including roof falls, gas explosions, and limited ventilation leading to poor air quality. Effective risk management in both methods requires specialized safety protocols tailored to the unique operational environments and geological conditions.

Equipment and Technology Requirements

Open-pit mining demands large-scale, heavy machinery such as haul trucks, shovels, and bulldozers specifically designed for surface operations, emphasizing capacity and durability for extensive material handling. Underground mining requires specialized equipment like continuous miners, roof bolters, and ventilation systems to ensure safety and efficiency in confined, subterranean environments. Advanced technologies such as automated drilling systems and real-time monitoring enhance operational precision and worker safety in both mining methods.

Ore Body Characteristics Influencing Mining Choice

Ore body depth, shape, and grade distribution are critical factors influencing the choice between open-pit and underground mining. Shallow, extensive, and uniformly distributed ore bodies typically favor open-pit mining due to economic feasibility and lower extraction costs. Conversely, deep, irregularly shaped, and high-grade ore bodies are more suitable for underground mining to minimize surface disturbance and optimize resource recovery.

Rehabilitation and Closure: Open-Pit vs. Underground Mines

Open-pit mine rehabilitation involves reshaping the landscape, replacing topsoil, and re-establishing vegetation to prevent erosion and promote biodiversity, often requiring extensive landform engineering due to large surface disturbances. Underground mine closure focuses on sealing shafts, ensuring long-term groundwater management, and stabilizing subsurface structures to prevent subsidence and environmental contamination. Regulatory frameworks emphasize tailored closure plans reflecting the distinct environmental impacts and risks associated with open-pit and underground mining operations.

Ventilation and Water Management Strategies

Open-pit mining requires extensive surface ventilation systems to control dust and exhaust gases, utilizing large-scale fans and open air circulation, while underground mining depends on complex, engineered ventilation shafts and ducting to ensure air quality and worker safety. Water management in open-pit operations typically involves large-scale dewatering pumps and surface runoff controls to prevent flooding and sedimentation, whereas underground mining employs sump systems and controlled groundwater inflow to maintain dry working conditions and prevent water hazards. Both mining types integrate advanced monitoring technologies to optimize airflow and water removal, minimizing environmental impact and operational risks.

Future Trends in Mining Methodologies

Future trends in mining methodologies emphasize automation and sustainability, with open-pit mining increasingly incorporating autonomous trucks and drones to enhance efficiency and safety. Underground mining is advancing through remote-controlled equipment and real-time sensor integration, enabling deeper, more precise extraction while minimizing environmental impact. Innovations like hybrid mining systems and AI-driven predictive maintenance are poised to transform both methods, optimizing resource recovery and reducing operational costs.

Stripping Ratio

The stripping ratio in open-pit mining is significantly higher than in underground mining, impacting operational costs and economic feasibility by determining the amount of waste material removed per unit of ore extracted.

Orebody Geometry

Open-pit mining is optimal for shallow, horizontally extensive orebodies, while underground mining suits deep, narrow, and vertically oriented orebodies.

Cut-off Grade

Cut-off grade in open-pit mining is generally higher due to lower extraction costs and easier access, while underground mining requires a lower cut-off grade to maintain economic viability despite higher operational expenses.

Pit Slope Stability

Pit slope stability in open-pit mining requires continuous monitoring and reinforcement to prevent landslides and ensure safe excavation, whereas underground mining relies more on controlled support systems to maintain tunnel integrity.

Ventilation Design

Ventilation design in open-pit mining prioritizes natural airflow and surface-based exhaust systems, whereas underground mining requires complex engineered ventilation networks with fans, airshafts, and air quality monitoring to ensure miner safety and optimal air circulation.

Waste Rock Management

Open-pit mining generates significantly larger volumes of waste rock requiring extensive management strategies to mitigate environmental impact compared to underground mining's limited waste rock production.

Block Caving

Block caving is an underground mining method that offers cost-effective extraction of large, massive ore bodies compared to the higher surface disruption and limited depth of open-pit mining.

Overburden Removal

Open-pit mining requires extensive overburden removal, often accounting for 70-90% of total material moved, whereas underground mining minimizes surface disturbance by limiting overburden removal.

Subsidence Control

Open-pit mining generally causes less surface subsidence than underground mining, which requires advanced subsidence control measures like backfilling and ground reinforcement to prevent ground collapse.

Haulage System

Open-pit mining uses large-scale truck haulage systems for efficient surface material transport, while underground mining relies on conveyor belts and rail haulage systems to navigate confined subterranean spaces.

open-pit vs underground mining Infographic

njnir.com

njnir.com