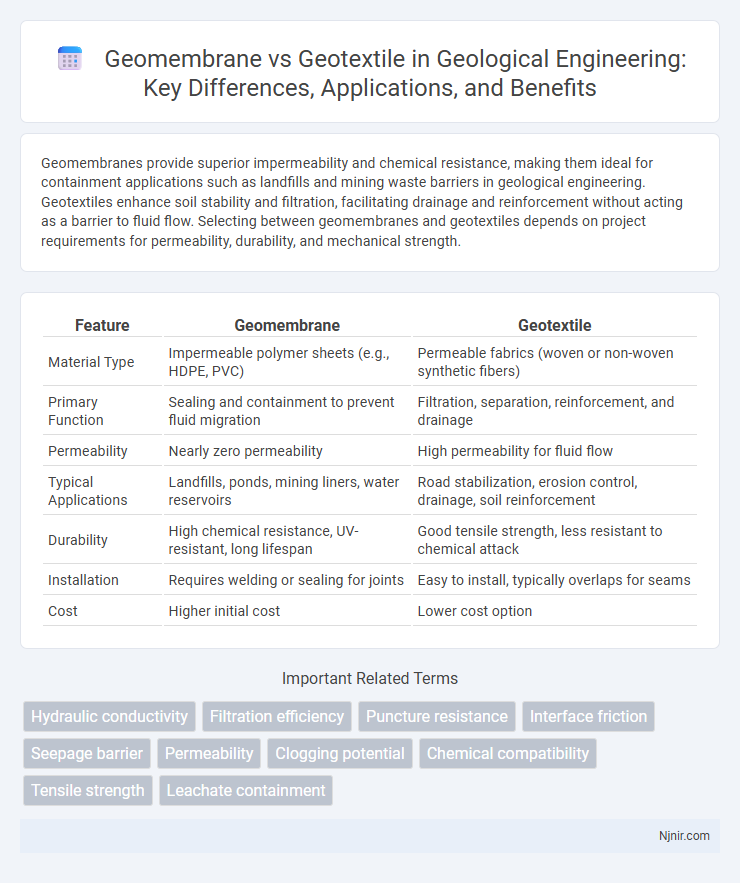

Geomembranes provide superior impermeability and chemical resistance, making them ideal for containment applications such as landfills and mining waste barriers in geological engineering. Geotextiles enhance soil stability and filtration, facilitating drainage and reinforcement without acting as a barrier to fluid flow. Selecting between geomembranes and geotextiles depends on project requirements for permeability, durability, and mechanical strength.

Table of Comparison

| Feature | Geomembrane | Geotextile |

|---|---|---|

| Material Type | Impermeable polymer sheets (e.g., HDPE, PVC) | Permeable fabrics (woven or non-woven synthetic fibers) |

| Primary Function | Sealing and containment to prevent fluid migration | Filtration, separation, reinforcement, and drainage |

| Permeability | Nearly zero permeability | High permeability for fluid flow |

| Typical Applications | Landfills, ponds, mining liners, water reservoirs | Road stabilization, erosion control, drainage, soil reinforcement |

| Durability | High chemical resistance, UV-resistant, long lifespan | Good tensile strength, less resistant to chemical attack |

| Installation | Requires welding or sealing for joints | Easy to install, typically overlaps for seams |

| Cost | Higher initial cost | Lower cost option |

Introduction to Geomembranes and Geotextiles

Geomembranes are impermeable synthetic membranes primarily used for lining and containment applications in environmental and civil engineering projects, providing a barrier to liquids and gases. Geotextiles consist of permeable fabrics designed to separate, filter, reinforce, protect, or drain soil and are essential in road construction, erosion control, and drainage systems. Both materials play critical roles in geotechnical engineering but differ significantly in function, composition, and application methods.

Material Composition and Manufacturing Processes

Geomembranes are composed primarily of synthetic polymers such as high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or polyvinyl chloride (PVC), manufactured through processes like extrusion or calendering to form continuous, impermeable sheets. Geotextiles consist mainly of natural or synthetic fibers such as polypropylene or polyester, produced using weaving, knitting, or nonwoven bonding techniques that result in permeable fabrics. The distinct material compositions and manufacturing methods influence their functionalities, with geomembranes providing impermeable barriers and geotextiles offering filtration, separation, and reinforcement capabilities.

Key Functional Differences

Geomembranes function primarily as impermeable barriers designed to prevent fluid migration in containment applications, typically made from synthetic polymers like HDPE or PVC. Geotextiles serve as filtration, separation, reinforcement, or drainage layers, constructed from woven or non-woven polypropylene or polyester fabrics that allow water flow while providing soil stabilization. The key functional difference lies in geomembranes providing a continuous, low-permeability barrier, whereas geotextiles enable gas or liquid permeability and mechanical support within soil structures.

Applications in Geological Engineering

Geomembranes provide impermeable barriers essential for containment applications such as landfill liners, mining tailings ponds, and water reservoir liners, ensuring the prevention of fluid migration. Geotextiles enhance soil stabilization, filtration, and drainage in slope reinforcement, erosion control, and foundation support by allowing water flow while maintaining soil integrity. Their complementary roles in geological engineering optimize site-specific solutions for environmental protection and structural stability.

Installation Methods and Techniques

Geomembrane installation requires precise seam welding using techniques such as hot wedge welding or extrusion welding to ensure impermeability, often supported by detailed surface preparation and anchoring methods. Geotextile installation involves unrolling and securing fabric layers with staples, pins, or sandbags, emphasizing overlap and drainage functionality rather than sealing seams. Both materials demand site-specific adjustments, including slope stabilization and protection layers, with geomembranes focusing on leak prevention and geotextiles on filtration and separation.

Mechanical and Chemical Properties

Geomembranes exhibit superior mechanical properties such as high tensile strength, puncture resistance, and low permeability, making them ideal for impermeable barriers in containment applications. Geotextiles offer excellent chemical resistance and filtration capabilities while providing moderate tensile strength and flexibility for soil stabilization and drainage. Both materials demonstrate durability, but geomembranes perform better under chemical exposure, whereas geotextiles excel in tensile reinforcement and separation functions.

Durability and Service Life

Geomembranes offer superior durability due to their impermeable polymeric construction, typically lasting 20 to 50 years depending on environmental exposure and material type. Geotextiles, made from woven or non-woven fibers, provide tensile strength and filtration but generally have shorter service lives, often ranging from 10 to 30 years. UV resistance, chemical stability, and mechanical properties are key factors influencing the longevity of both geomembranes and geotextiles in various civil engineering applications.

Cost Considerations and Economic Impact

Geomembranes typically have higher initial costs due to specialized materials like high-density polyethylene (HDPE) and complex installation requirements, but their superior impermeability reduces long-term maintenance expenses in containment applications. Geotextiles offer a more economical upfront investment, serving as filtration, separation, and drainage solutions with easier installation and lower material costs, yet may require replacement or supplementary layers over time. Evaluating project lifespan and specific functional demands is crucial for balancing upfront expenditure against potential economic benefits and sustainability in infrastructure and environmental projects.

Performance in Environmental Protection

Geomembranes provide superior impermeability, effectively preventing the migration of contaminants in landfills and water containment systems, making them ideal for environmental protection. Geotextiles primarily function as filtration, separation, and reinforcement materials, allowing fluid flow while maintaining soil stability but do not offer a complete barrier against pollutants. Combining geomembranes with geotextiles often enhances overall system performance by integrating impermeability with structural support in environmental applications.

Selection Criteria for Geological Projects

Selection criteria for geological projects prioritize geomembranes when impermeability and chemical resistance are essential, such as in landfill liners or containment systems. Geotextiles are preferred for filtration, drainage, and soil reinforcement applications, where permeability and tensile strength improve soil stability. Project-specific factors like soil type, environmental conditions, load-bearing requirements, and expected lifespan guide the optimal choice between geomembrane and geotextile materials.

Hydraulic conductivity

Geomembranes exhibit extremely low hydraulic conductivity, typically less than 1x10^-13 m/s, making them superior to geotextiles, whose higher permeability allows greater fluid flow and limits their effectiveness as impermeable barriers.

Filtration efficiency

Geotextiles provide superior filtration efficiency by allowing water passage while retaining soil particles, whereas geomembranes act as impermeable barriers with minimal filtration capability.

Puncture resistance

Geomembranes provide superior puncture resistance compared to geotextiles due to their dense, impermeable synthetic composition designed to withstand sharp objects and heavy loads.

Interface friction

Geomembranes exhibit lower interface friction compared to geotextiles, influencing their stability and interaction in layered soil systems.

Seepage barrier

Geomembranes provide a more effective seepage barrier than geotextiles due to their low permeability and impermeable properties.

Permeability

Geomembranes exhibit near-zero permeability ideal for impermeable barriers, whereas geotextiles possess higher permeability to facilitate drainage and filtration in soil applications.

Clogging potential

Geomembranes exhibit significantly lower clogging potential compared to geotextiles due to their impermeable synthetic barrier properties, which prevent particle infiltration and maintain long-term filtration efficiency.

Chemical compatibility

Geomembranes exhibit superior chemical compatibility with a wide range of aggressive substances compared to geotextiles, making them ideal for containment and barrier applications in harsh chemical environments.

Tensile strength

Geomembranes typically exhibit higher tensile strength ranging from 1,000 to 3,000 kN/m compared to geotextiles, which generally have tensile strengths between 50 and 400 kN/m, making geomembranes more suitable for applications requiring superior resistance to stretching and tearing.

Leachate containment

Geomembranes provide superior leachate containment compared to geotextiles due to their impermeable barrier properties essential for preventing groundwater contamination in waste management systems.

geomembrane vs geotextile Infographic

njnir.com

njnir.com