Triaxial tests provide a more comprehensive understanding of soil behavior under simulated in-situ stress conditions compared to uniaxial tests, which apply stress in only one direction. The triaxial test measures shear strength, cohesion, and internal friction angle more accurately by controlling both axial and confining pressures, essential for stability analysis in geological engineering. Uniaxial tests are simpler and useful for preliminary assessments but lack the ability to replicate complex stress states that soils experience in the field.

Table of Comparison

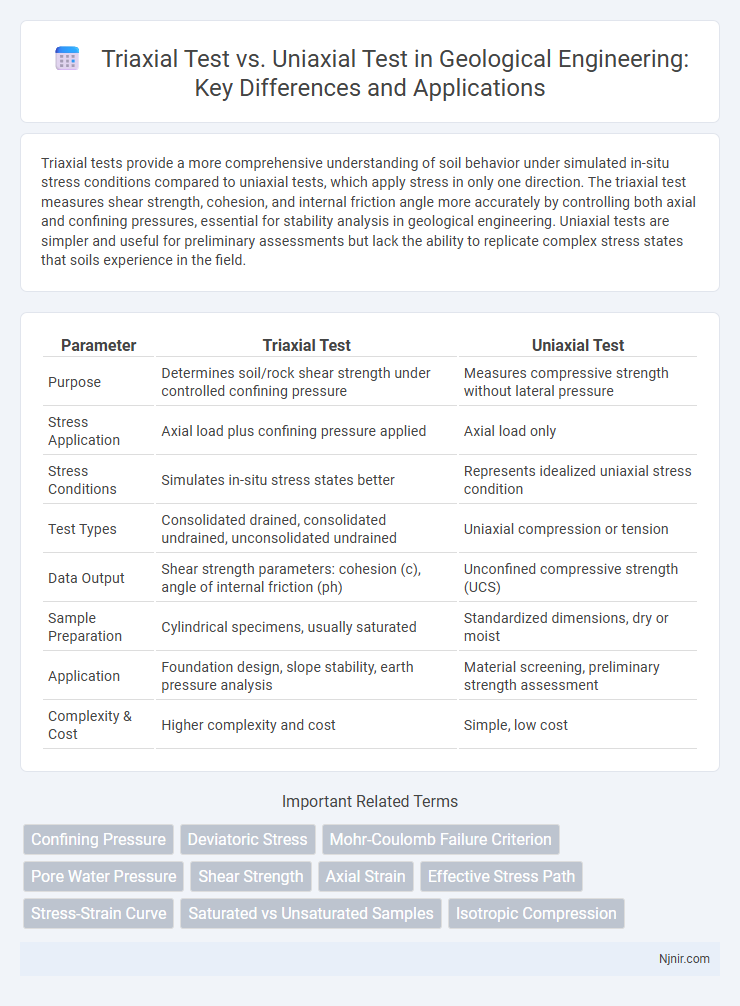

| Parameter | Triaxial Test | Uniaxial Test |

|---|---|---|

| Purpose | Determines soil/rock shear strength under controlled confining pressure | Measures compressive strength without lateral pressure |

| Stress Application | Axial load plus confining pressure applied | Axial load only |

| Stress Conditions | Simulates in-situ stress states better | Represents idealized uniaxial stress condition |

| Test Types | Consolidated drained, consolidated undrained, unconsolidated undrained | Uniaxial compression or tension |

| Data Output | Shear strength parameters: cohesion (c), angle of internal friction (ph) | Unconfined compressive strength (UCS) |

| Sample Preparation | Cylindrical specimens, usually saturated | Standardized dimensions, dry or moist |

| Application | Foundation design, slope stability, earth pressure analysis | Material screening, preliminary strength assessment |

| Complexity & Cost | Higher complexity and cost | Simple, low cost |

Introduction to Geomechanical Testing Methods

Triaxial tests provide detailed insights into soil strength and deformation by applying controlled axial and confining pressures, simulating in-situ stress conditions more accurately than uniaxial tests. Uniaxial tests measure strength under a single load direction, making them simpler but less representative of complex stress states in geotechnical applications. Geomechanical testing combines these methods to evaluate soil behavior for foundational design, slope stability, and earth retention systems.

Fundamental Principles: Triaxial vs. Uniaxial Testing

Triaxial testing measures soil or rock strength by applying pressure from all directions, simulating true stress states and controlling drainage conditions, whereas uniaxial testing applies stress in only one direction, providing less realistic stress conditions. The triaxial test's ability to vary confining pressure and shear stress independently enables more accurate determination of mechanical properties such as cohesion and internal friction angle. Uniaxial testing primarily assesses compressive or tensile strength but lacks the capacity to replicate the multidirectional stresses experienced in situ.

Test Apparatus and Experimental Setup

The triaxial test apparatus consists of a cylindrical soil sample enclosed in a rubber membrane, subjected to controlled axial and radial stresses using a loading frame and a pressure chamber, enabling precise simulation of complex stress conditions. In contrast, the uniaxial test apparatus applies load only along one axis, typically using a simple loading machine, making it less effective for capturing multi-directional stress responses. The experimental setup for triaxial tests involves saturation, consolidation, and drainage conditions, whereas the uniaxial test setup is more straightforward, focusing primarily on axial loading without pore pressure measurements.

Sample Preparation in Triaxial and Uniaxial Tests

Sample preparation for triaxial tests requires cylindrical soil specimens carefully trimmed to preserve in-situ structure, with standardized dimensions typically around 38 mm diameter and 76 mm height to ensure uniform stress application. Uniaxial tests involve simpler sample shapes, often rectangular or cylindrical, but demand precise alignment and machining to avoid eccentric loading and ensure accurate tensile or compressive strength measurement. Both methods emphasize moisture content control and surface smoothness to prevent premature failure and achieve reliable, reproducible mechanical property data.

Key Parameters Measured in Both Tests

The triaxial test measures shear strength, pore water pressure, and effective stress under controlled confining pressure, providing a comprehensive understanding of soil behavior under realistic stress conditions. The uniaxial test primarily focuses on unconfined compressive strength and axial strain without accounting for lateral confinement or pore pressure changes. Both tests assess soil strength parameters, but the triaxial test offers deeper insights by simulating three-dimensional stress states critical for geotechnical design.

Stress-Strain Behavior Comparison

Triaxial tests provide a more comprehensive understanding of soil behavior under multi-axial stress conditions by measuring axial and radial stresses simultaneously, while uniaxial tests apply stress in only one direction. Stress-strain curves from triaxial tests typically show distinct phases of elastic deformation, plastic deformation, and strain hardening or softening, reflecting real field conditions more accurately compared to the simpler linear-elastic behavior often observed in uniaxial tests. The triaxial test's ability to simulate confining pressure leads to more realistic failure envelopes and improved predictions of soil strength and deformation characteristics under various loading scenarios.

Applications in Geological Engineering

Triaxial tests provide detailed insights into soil shear strength, pore water pressure, and stress-strain behavior under controlled confining pressure, making them essential for slope stability analysis, foundation design, and earth dam construction. Uniaxial tests, while simpler, primarily measure compressive strength and are commonly applied in rock mechanics to evaluate unconfined compressive strength for tunnel design and excavation support. The triaxial test's ability to simulate in-situ stress conditions offers superior accuracy for assessing soil behavior under complex loading in geological engineering projects.

Advantages and Limitations of Each Test

The triaxial test offers precise simulation of in-situ stress conditions, enabling measurement of shear strength and deformation characteristics under controlled drainage conditions, but requires complex equipment and longer testing times. The uniaxial test provides rapid assessment of compressive strength and modulus with simpler setup and lower cost, yet fails to replicate lateral stresses, limiting its accuracy for predicting real soil behavior. Each test complements soil analysis by balancing practical constraints and detailed mechanical insights essential for geotechnical design.

Interpretation of Test Results

Interpretation of triaxial test results provides detailed insights into soil shear strength parameters such as cohesion, angle of internal friction, and pore water pressure, enabling more accurate assessment of soil behavior under varying confining pressures. In contrast, uniaxial test results primarily yield compressive strength without accounting for lateral stress effects, limiting their applicability in predicting soil performance under field stress conditions. The triaxial test's ability to simulate in-situ stress states makes its results more reliable for geotechnical design and stability analysis.

Implications for Engineering Design and Practice

Triaxial tests provide comprehensive data on soil behavior under controlled stress conditions, enabling engineers to accurately determine shear strength parameters, critical for foundation design and slope stability analysis. Uniaxial tests, while simpler, offer limited insights as they only measure strength under one-directional loading, often leading to conservative or less reliable design assumptions. Incorporating triaxial test results enhances the precision of geotechnical models, leading to safer and more cost-effective engineering practices.

Confining Pressure

Triaxial tests apply varying confining pressure to simulate in-situ stress conditions and measure soil strength, whereas uniaxial tests do not incorporate confining pressure, leading to different stress and failure characteristics.

Deviatoric Stress

Deviatoric stress in triaxial tests provides a more accurate measurement of soil shear strength under controlled confining pressure compared to the uniaxial test, which lacks lateral stress application.

Mohr-Coulomb Failure Criterion

The triaxial test provides a more accurate determination of soil shear strength parameters under Mohr-Coulomb failure criterion by simulating three-dimensional stress states, unlike the uniaxial test which applies only a single axial stress.

Pore Water Pressure

The triaxial test provides detailed measurements of pore water pressure changes under controlled drainage conditions, whereas the uniaxial test generally lacks precise pore water pressure data due to its simpler loading setup.

Shear Strength

The triaxial test provides a more accurate measurement of soil shear strength under simulated field stresses compared to the uniaxial test, which only applies vertical loading.

Axial Strain

The triaxial test provides more accurate axial strain measurements under simulated in-situ stress conditions compared to the uniaxial test, which only applies axial load without confining pressure.

Effective Stress Path

The triaxial test provides a detailed effective stress path by simultaneously measuring axial and radial stresses under controlled drainage conditions, unlike the uniaxial test which records only axial stress without capturing pore pressure effects.

Stress-Strain Curve

The triaxial test produces a more detailed stress-strain curve reflecting soil behavior under controlled confining pressure, while the uniaxial test provides a simpler curve representing material response under direct axial loading without lateral confinement.

Saturated vs Unsaturated Samples

Saturated samples in triaxial tests exhibit pore water pressure behavior critical for effective stress analysis, while unsaturated samples require suction measurement to assess matric potential effects not captured in uniaxial tests.

Isotropic Compression

Isotropic compression in triaxial tests uniformly applies confining pressure to soil samples, enabling more accurate simulation of in-situ stress conditions compared to uniaxial tests that apply stress in a single direction.

triaxial test vs uniaxial test Infographic

njnir.com

njnir.com