Deep excavation involves removing soil or rock to significant depths, requiring advanced support systems like retaining walls and bracing to prevent collapse, while shallow excavation is limited to near-surface layers with minimal support. Deep excavation poses higher risks related to groundwater control and soil stability, demanding comprehensive geotechnical analysis, whereas shallow excavation typically impacts surface layers with less complex safety measures. Selecting between deep and shallow excavation depends on project scope, site conditions, and structural requirements.

Table of Comparison

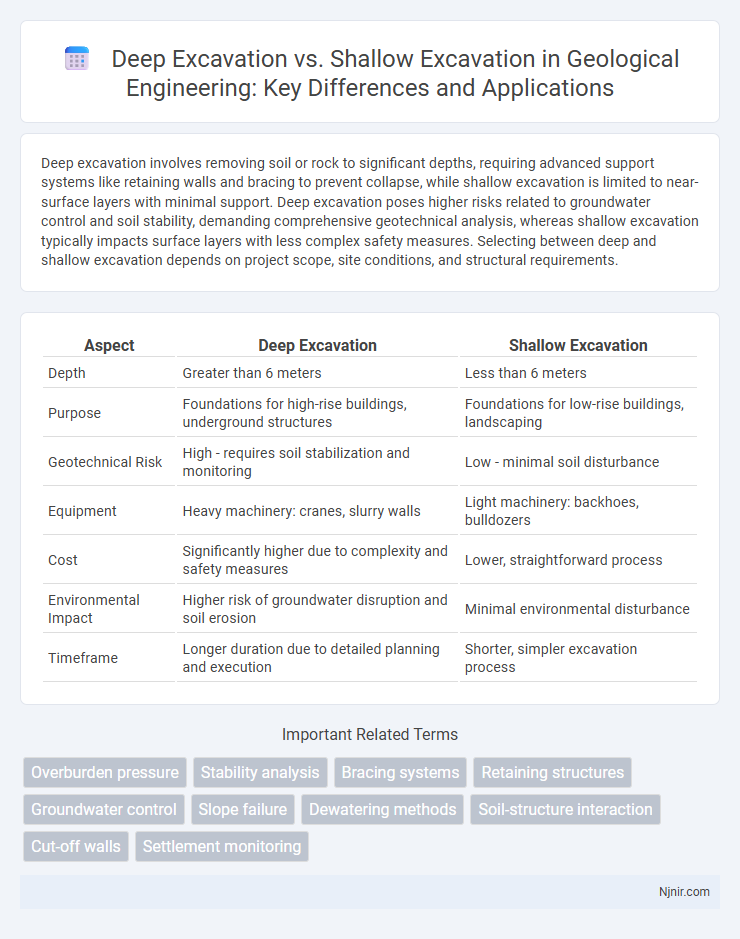

| Aspect | Deep Excavation | Shallow Excavation |

|---|---|---|

| Depth | Greater than 6 meters | Less than 6 meters |

| Purpose | Foundations for high-rise buildings, underground structures | Foundations for low-rise buildings, landscaping |

| Geotechnical Risk | High - requires soil stabilization and monitoring | Low - minimal soil disturbance |

| Equipment | Heavy machinery: cranes, slurry walls | Light machinery: backhoes, bulldozers |

| Cost | Significantly higher due to complexity and safety measures | Lower, straightforward process |

| Environmental Impact | Higher risk of groundwater disruption and soil erosion | Minimal environmental disturbance |

| Timeframe | Longer duration due to detailed planning and execution | Shorter, simpler excavation process |

Introduction to Excavation in Geological Engineering

Excavation in geological engineering involves removing earth materials to create foundations, tunnels, or other structures, with deep excavation targeting substantial depths often exceeding several meters to access stable strata or avoid surface disturbances. Shallow excavation typically involves removing soil to depths of less than three meters for foundations or utility installations, emphasizing minimal disruption and ease of construction. Understanding soil mechanics, groundwater conditions, and slope stability is crucial in designing safe and effective excavation strategies for both deep and shallow projects.

Defining Deep and Shallow Excavation

Deep excavation involves digging below 20 feet (6 meters), typically requiring extensive shoring systems to ensure structural stability and safety. Shallow excavation generally refers to depths less than 20 feet, often used for foundations, utility trenches, and landscaping without complex support systems. The distinction impacts construction planning, cost, and risk management significantly.

Geological Factors Influencing Excavation Depth

Geological factors such as soil composition, groundwater levels, and rock stability critically influence the choice between deep and shallow excavation. Deep excavation often requires careful assessment of load-bearing strata and slope stability to prevent collapses, especially in clayey or sandy soils prone to liquefaction. Shallow excavation is preferred in areas with strong, stable bedrock near the surface, minimizing the need for extensive shoring or dewatering systems.

Techniques Used in Deep Excavation

Deep excavation techniques include diaphragm walls, soldier piles with lagging, and secant piles, which provide strong soil support and minimize ground movement in urban construction. These methods enable safe excavation depths beyond 6 meters by stabilizing soil and controlling groundwater through dewatering systems. Advanced monitoring technologies like inclinometers and piezometers are often integrated to ensure structural safety during deep excavation projects.

Methods Applied in Shallow Excavation

Shallow excavation methods primarily include open cut, benching, and sloping techniques, designed to maintain site stability while minimizing soil disturbance. These methods typically involve removing soil layers up to a limited depth, often less than 3 meters, using machinery like backhoes and excavators to ensure efficient material handling. Soil support systems such as sheet piling and soldier piles are less commonly required in shallow excavations, which focus on easier access and lower construction costs compared to deep excavation.

Stability and Safety Considerations

Deep excavation demands advanced structural support systems such as soldier piles, diaphragm walls, or secant piles to prevent soil collapse and ensure site stability. Shallow excavation typically relies on natural soil strength and temporary bracing but poses less risk of destabilizing adjacent structures. Both methods require rigorous monitoring and adherence to safety standards to mitigate hazards like trench collapse, groundwater seepage, and soil erosion.

Equipment and Technology Comparison

Deep excavation projects utilize advanced heavy-duty equipment such as long-reach excavators, diaphragm wall grabbers, and ground freezing technology to ensure stability and safety in challenging subsurface conditions. Shallow excavation typically employs standard excavators, backhoes, and simpler soil stabilization methods suited for less complex environments, resulting in faster cycle times and lower equipment costs. Technological integration like real-time monitoring sensors and Building Information Modeling (BIM) is more prominent in deep excavation to manage risks and optimize operations.

Cost Implications of Deep vs Shallow Excavations

Deep excavation projects typically incur significantly higher costs than shallow excavations due to the need for extensive shoring systems, dewatering measures, and specialized labor. The complexity of deep excavation increases material use, equipment requirements, and safety measures, leading to elevated overall project expenses. Shallow excavations generally offer cost savings by reducing these factors, making them more economical for projects with less depth requirements.

Environmental Impact Assessment

Deep excavation often poses a higher environmental impact due to increased soil disturbance, groundwater disruption, and potential contamination risks compared to shallow excavation. Environmental Impact Assessments (EIA) focus on evaluating these risks by analyzing factors such as sediment runoff, noise pollution, and ecosystem disruption associated with deep excavation processes. In contrast, shallow excavation generally results in lower emissions and less habitat disturbance, making its environmental footprint comparatively minimal in EIA reports.

Applications and Case Studies in Engineering Projects

Deep excavation is commonly applied in urban infrastructure projects such as subway stations, high-rise building foundations, and underground parking structures, where significant earth removal is required to reach stable strata or accommodate complex underground networks. Shallow excavation is favored for residential construction, landscaping, and utility trenches where minimal soil displacement suffices, providing cost-effective and faster completion times. Case studies in engineering highlight deep excavation in the Crossrail project in London, demonstrating advanced support systems like diaphragm walls, while shallow excavation has proven effective in highway expansion projects due to reduced environmental impact and simpler site management.

Overburden pressure

Deep excavation experiences significantly higher overburden pressure compared to shallow excavation, requiring advanced support systems to ensure slope stability and prevent soil failure.

Stability analysis

Deep excavation stability analysis requires advanced soil-structure interaction modeling and robust support systems, whereas shallow excavation primarily depends on simpler slope stability assessments and temporary shoring methods.

Bracing systems

Deep excavation requires robust bracing systems such as soldier piles, struts, and tiebacks to resist higher lateral earth pressures, whereas shallow excavation typically utilizes simpler bracing like timber shoring or sheet piles due to lower soil loads.

Retaining structures

Deep excavation requires robust retaining structures such as diaphragm walls or soldier piles to withstand significant lateral earth pressures, whereas shallow excavation typically uses simpler retaining methods like sheet piles or bracing due to lower soil load demands.

Groundwater control

Deep excavation requires advanced groundwater control techniques such as dewatering wells and cutoff walls, while shallow excavation typically relies on simpler methods like sump pumps and localized drainage.

Slope failure

Deep excavation poses a higher risk of slope failure due to increased soil pressure and instability compared to shallow excavation.

Dewatering methods

Deep excavation requires advanced dewatering methods such as wellpoint systems and deep wells to control high groundwater levels, while shallow excavation typically relies on simpler techniques like sump pumping and drainage trenches for effective water removal.

Soil-structure interaction

Deep excavation significantly influences soil-structure interaction by inducing higher lateral earth pressures and complex stress redistributions compared to shallow excavation, requiring advanced support systems to maintain stability.

Cut-off walls

Cut-off walls in deep excavation provide superior groundwater control and structural stability compared to shallow excavation, which typically relies on simpler barriers and is less effective in preventing water inflow.

Settlement monitoring

Settlement monitoring during deep excavation employs advanced geotechnical instruments and continuous real-time data analysis to manage greater ground displacement risks compared to shallow excavation methods.

Deep excavation vs Shallow excavation Infographic

njnir.com

njnir.com