Soil nailing stabilizes slopes by reinforcing existing soil with closely spaced steel bars, providing efficient support for shallow excavations and retaining walls. Micro-piling uses small-diameter, high-capacity piles drilled deep into the ground to transfer loads through weak soil layers to stronger strata, suitable for underpinning and foundation strengthening. Both techniques enhance ground stability but differ in installation complexity, load capacity, and application depth.

Table of Comparison

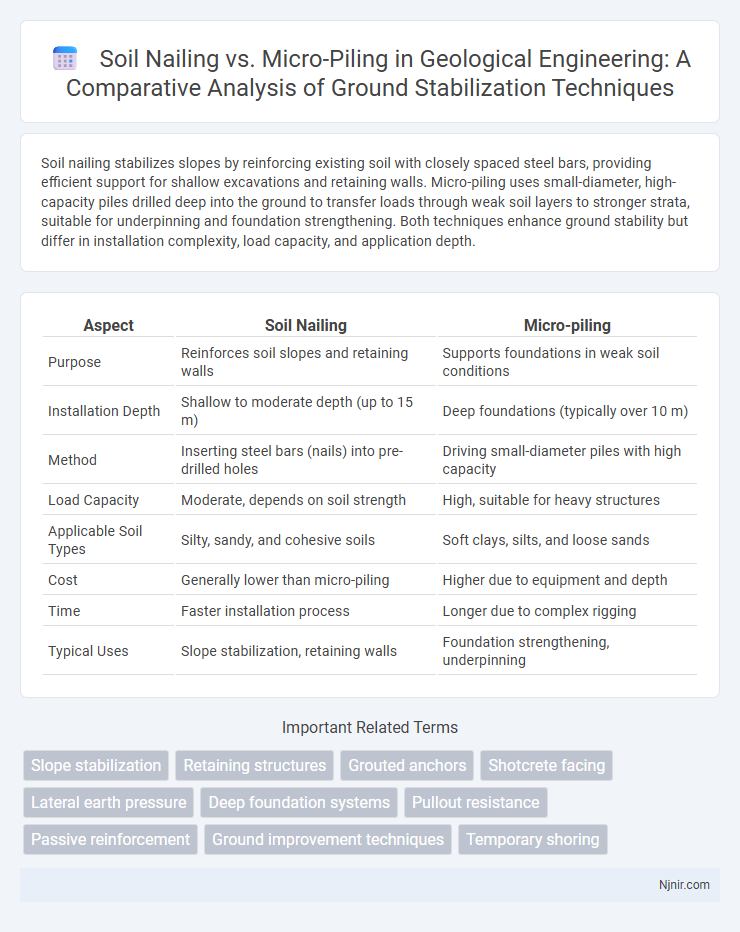

| Aspect | Soil Nailing | Micro-piling |

|---|---|---|

| Purpose | Reinforces soil slopes and retaining walls | Supports foundations in weak soil conditions |

| Installation Depth | Shallow to moderate depth (up to 15 m) | Deep foundations (typically over 10 m) |

| Method | Inserting steel bars (nails) into pre-drilled holes | Driving small-diameter piles with high capacity |

| Load Capacity | Moderate, depends on soil strength | High, suitable for heavy structures |

| Applicable Soil Types | Silty, sandy, and cohesive soils | Soft clays, silts, and loose sands |

| Cost | Generally lower than micro-piling | Higher due to equipment and depth |

| Time | Faster installation process | Longer due to complex rigging |

| Typical Uses | Slope stabilization, retaining walls | Foundation strengthening, underpinning |

Introduction to Soil Nailing and Micro-piling

Soil nailing stabilizes slopes and excavations by reinforcing soil with closely spaced, steel bars that are grouted into drilled holes, enhancing soil strength and preventing collapse. Micro-piling involves installing small-diameter, high-capacity piles to support foundations in weak or restricted sites, transferring loads to deeper, stable strata. Both techniques provide effective ground support but differ in application methods and structural load capacities.

Fundamentals and Mechanisms of Soil Nailing

Soil nailing involves reinforcing existing soil by inserting closely spaced steel bars, or nails, into pre-drilled holes, which are then grouted to create a composite mass that improves soil stability through increased shear strength and reduced deformation. The mechanism relies on the passive resistance of the soil against the nails, transferring load from the unstable soil to the more stable zones, effectively creating a retaining structure without extensive excavation. Unlike micro-piling that uses deep foundations to transfer loads to bedrock or dense soil layers, soil nailing strengthens slopes and excavation faces by improving soil cohesion and internal friction through the interaction of nails and soil matrix.

Principles and Applications of Micro-piling

Micro-piling involves installing small-diameter, high-capacity reinforced concrete piles to support or underpin existing foundations, especially in areas with limited access or challenging ground conditions. This technique transfers structural loads to deeper, more stable soil or rock layers, making it ideal for strengthening foundations, underpinning buildings, and supporting heavy structures in urban environments. Soil nailing, by contrast, reinforces slopes or excavations by inserting closely spaced steel bars into the ground and grouting them to improve soil stability without deep foundation support.

Comparative Design Considerations

Soil nailing involves reinforcing existing soil by inserting steel bars at regular intervals, ideal for stabilizing slopes and retaining walls with limited excavation, while micro-piling uses small-diameter piles to transfer loads to deeper, more stable strata, suitable for weak or variable soil conditions. Design considerations for soil nailing focus on soil type, nail length, spacing, and corrosion protection to ensure adequate pullout resistance and slope stability. Micro-piling design requires analysis of bearing capacity, pile load distribution, installation methods, and potential ground vibrations to support heavy structural loads in challenging geotechnical environments.

Construction Techniques and Equipment Overview

Soil nailing involves installing closely spaced steel bars into a slope or excavation face to reinforce existing soil using drilling rigs and grouting equipment, providing immediate stabilization with minimal heavy machinery. Micro-piling employs small-diameter, high-capacity reinforced concrete piles driven or drilled deep into the ground using specialized micro-piling rigs and hydraulic hammers, suitable for supporting heavy structural loads in restricted access sites. Both techniques require precise geotechnical analysis and are chosen based on site conditions, load requirements, and equipment accessibility.

Load-Bearing Capacity and Performance Analysis

Soil nailing provides enhanced reinforcement by installing closely spaced steel bars that improve slope stability and resist lateral earth pressures with moderate load-bearing capacity suitable for shallow excavations. Micro-piling involves installing small-diameter, high-capacity piles that transfer loads to deeper, more stable soil strata, offering superior load-bearing capacity for heavy structural support in weak or variable ground conditions. Performance analysis indicates that micro-piling delivers greater axial and lateral load resistance, while soil nailing excels in controlling surface deformations and reinforcing existing slopes.

Suitability for Soil Types and Ground Conditions

Soil nailing is highly effective in stable, dense soils like clay and silty sand, providing reinforcement through the installation of steel bars to prevent slope failure or excavations in cohesive ground. Micro-piling offers superior suitability for weak, heterogeneous, or water-saturated soils, enabling deep foundation support through small-diameter piles that transfer loads to stable strata. Understanding soil characteristics and groundwater conditions is crucial to selecting between soil nailing's shallow stabilization and micro-piling's deep foundational support.

Cost, Time, and Project Efficiency Comparison

Soil nailing typically offers lower costs and faster installation times compared to micro-piling, making it ideal for moderate load support and retaining walls in urban environments. Micro-piling, despite higher initial expenses, provides superior load-bearing capacity and is more efficient for projects requiring deep foundations or challenging ground conditions. Project efficiency depends on site-specific factors, where soil nailing excels in speed and cost-effectiveness, while micro-piling ensures long-term stability and versatility in complex geotechnical scenarios.

Case Studies: Successful Implementations

Soil nailing has been successfully implemented in urban excavation projects, such as the Big Dig in Boston, where it provided efficient slope stabilization and minimized disruption. Micro-piling has demonstrated effectiveness in foundation reinforcement for structures on weak soils, exemplified by the Tokyo Skytree, which uses micro-piles for deep foundation support under seismic loads. Both techniques offer tailored solutions based on site-specific geotechnical conditions, optimizing structural safety and cost-efficiency.

Choosing the Right Solution: Decision Criteria

Soil nailing is best suited for stabilizing existing slopes and retaining walls with shallow to moderate depth requirements, offering cost-effective and rapid construction for cohesive soils. Micro-piling is preferred for deep foundation support in challenging ground conditions such as loose, soft, or contaminated soils, where high load capacity and minimal vibration are critical. Key decision criteria include soil type, load requirements, site accessibility, project budget, and environmental impact.

Slope stabilization

Soil nailing provides cost-effective slope stabilization by reinforcing existing soil with steel bars, while micro-piling enables deep foundation support for slopes with weak or heterogeneous ground conditions.

Retaining structures

Soil nailing stabilizes retaining structures by reinforcing existing soil with steel bars, while micro-piling provides deep foundational support by installing small-diameter piles to transfer loads to stable strata.

Grouted anchors

Grouted anchors in soil nailing provide improved ground stability by reinforcing slopes with closely spaced, tensioned steel bars, whereas micro-piling relies on small-diameter, high-capacity piles to transfer loads to deeper, stable strata for foundation support.

Shotcrete facing

Shotcrete facing in soil nailing provides immediate surface stabilization and erosion control, whereas micro-piling typically does not incorporate shotcrete, focusing instead on deep foundation support without surface facing.

Lateral earth pressure

Soil nailing reduces lateral earth pressure by reinforcing existing soil to create a stable mass, while micro-piling transfers lateral loads to deeper, more stable strata, effectively controlling lateral earth pressure in different soil conditions.

Deep foundation systems

Soil nailing stabilizes slopes by reinforcing existing soil with steel bars, while micro-piling provides deep foundation support through small-diameter, high-capacity piles ideal for load transfer in weak soil conditions.

Pullout resistance

Soil nailing typically offers lower pullout resistance due to shallower embedment compared to micro-piling, which provides higher pullout capacity through deep foundation elements anchored in stable strata.

Passive reinforcement

Soil nailing provides passive reinforcement by inserting closely spaced steel bars into the soil to stabilize slopes, while micro-piling offers passive support through small-diameter, deep foundation elements that transfer load to stable strata.

Ground improvement techniques

Soil nailing enhances ground stability by reinforcing existing soil with steel bars, while micro-piling improves ground support through deep, small-diameter piles that transfer load to stable strata.

Temporary shoring

Soil nailing offers cost-effective, rapid temporary shoring for stable slopes by reinforcing in-situ soil, while micro-piling provides deep, load-bearing temporary support in weak soils with minimal vibration and environmental impact.

Soil nailing vs Micro-piling Infographic

njnir.com

njnir.com