Direct shear tests measure soil shear strength by applying horizontal force along a predefined plane, offering simplicity and quick results while limiting stress condition control. Triaxial tests provide a comprehensive assessment of soil mechanical properties under controlled confining pressure, simulating real field stress conditions with precise measurement of shear strength and deformation parameters. Understanding the differences in stress application and data output between these tests is essential for selecting appropriate methods in slope stability and foundation design.

Table of Comparison

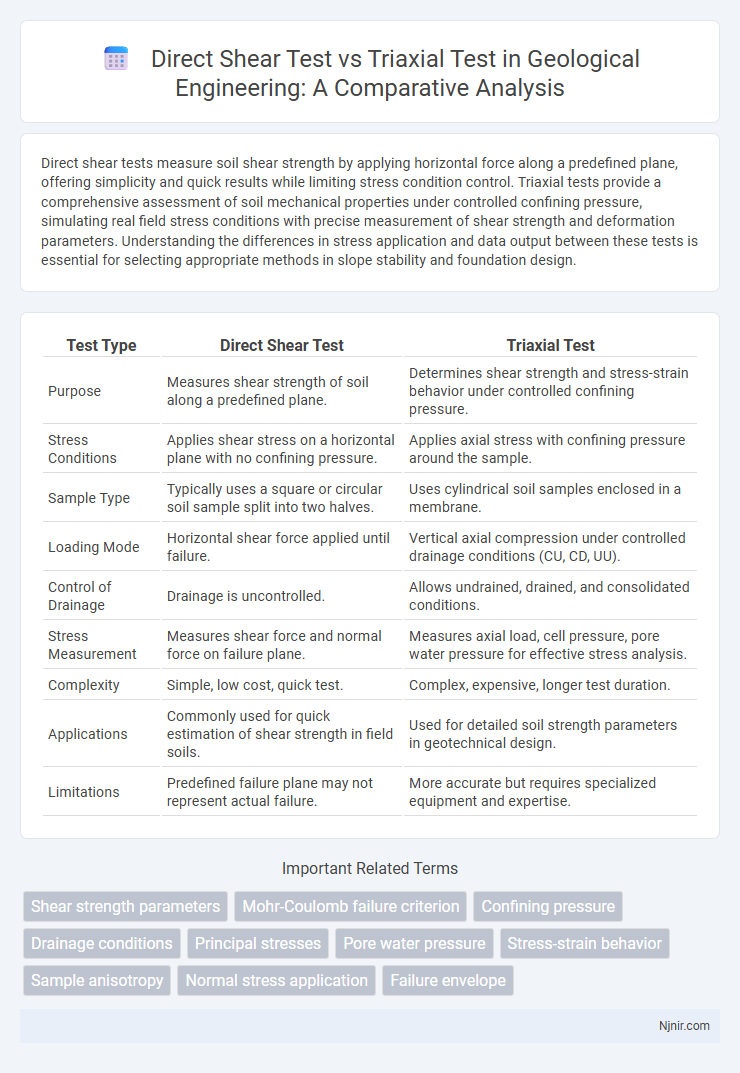

| Test Type | Direct Shear Test | Triaxial Test |

|---|---|---|

| Purpose | Measures shear strength of soil along a predefined plane. | Determines shear strength and stress-strain behavior under controlled confining pressure. |

| Stress Conditions | Applies shear stress on a horizontal plane with no confining pressure. | Applies axial stress with confining pressure around the sample. |

| Sample Type | Typically uses a square or circular soil sample split into two halves. | Uses cylindrical soil samples enclosed in a membrane. |

| Loading Mode | Horizontal shear force applied until failure. | Vertical axial compression under controlled drainage conditions (CU, CD, UU). |

| Control of Drainage | Drainage is uncontrolled. | Allows undrained, drained, and consolidated conditions. |

| Stress Measurement | Measures shear force and normal force on failure plane. | Measures axial load, cell pressure, pore water pressure for effective stress analysis. |

| Complexity | Simple, low cost, quick test. | Complex, expensive, longer test duration. |

| Applications | Commonly used for quick estimation of shear strength in field soils. | Used for detailed soil strength parameters in geotechnical design. |

| Limitations | Predefined failure plane may not represent actual failure. | More accurate but requires specialized equipment and expertise. |

Introduction to Soil Shear Strength Testing

Soil shear strength testing is essential for understanding soil stability and bearing capacity in geotechnical engineering. The direct shear test measures shear strength by applying a horizontal force to a soil sample along a predetermined plane, providing peak and residual shear strength values. The triaxial test subjects a cylindrical soil specimen to controlled axial and confining pressures, enabling detailed analysis of shear strength parameters under simulated in-situ stress conditions.

Principles of the Direct Shear Test

The Direct Shear Test measures soil shear strength by applying a horizontal force to a soil sample confined within a shear box, causing failure along a predetermined plane. This method relies on controlling normal stress while recording the peak shear stress to determine the soil's shear resistance. The principles emphasize a simple setup that isolates the shear plane, allowing for direct observation of soil behavior under shear loading conditions.

Fundamentals of the Triaxial Test

The triaxial test measures soil shear strength by applying confining pressure and axial stress to a cylindrical sample, closely simulating in-situ stress conditions, unlike the direct shear test which applies shear force directly on a predetermined plane. Key parameters such as pore water pressure, deviator stress, and confining pressure are recorded in the triaxial test to evaluate effective stress behavior and failure mechanisms. The triaxial test provides comprehensive data on soil strength, deformation, and consolidation characteristics, essential for geotechnical design and analysis.

Equipment and Setup Comparison

The direct shear test utilizes a simple shear box apparatus where a soil sample is placed between two horizontal plates, and shear force is applied laterally until failure occurs, allowing measurement of shear strength parameters such as cohesion and friction angle. The triaxial test involves a cylindrical soil specimen enclosed within a latex membrane, placed in a pressure chamber filled with fluid to apply confining pressure, with axial load applied via a loading piston to simulate in-situ stress conditions and determine strength under controlled drainage conditions. Equipment for the triaxial test is more complex and precise, enabling control over pore water pressure and stress paths, whereas the direct shear test is more straightforward and quicker but provides less detailed stress-strain behavior insight.

Test Procedures and Sample Preparation

Direct shear tests involve placing a soil sample in a shear box, applying vertical stress, and then shearing the sample along a predetermined plane to measure shear strength. Triaxial tests require preparing cylindrical soil specimens encased in a rubber membrane, subjecting them to confining pressure in a triaxial chamber, and incrementally increasing axial load until failure, allowing control over drainage conditions. Sample preparation for direct shear tests is simpler, often involving remolding soil into the shear box, whereas triaxial tests demand careful specimen trimming and saturation to preserve in-situ soil structure for accurate results.

Stress Conditions and Drainage Control

Direct shear tests apply shear stress along a predetermined failure plane, typically under drained conditions allowing pore water pressure dissipation, while triaxial tests simulate more complex stress states by applying axial and confining pressures, enabling both drained and undrained tests with precise drainage control. In triaxial testing, pore pressure gauges monitor and regulate drainage, facilitating effective measurement of effective stress and shear strength parameters under various drainage conditions. Direct shear tests lack sophisticated drainage control and stress path flexibility compared to triaxial tests, limiting their ability to reproduce in-situ stress conditions accurately.

Advantages and Limitations of Direct Shear Test

The direct shear test offers advantages such as simplicity, rapid execution, and minimal equipment requirements, making it highly suitable for on-site soil shear strength assessment. However, its limitations include an inability to simulate complex stress paths, non-uniform shear stress distribution along the failure plane, and constraints in testing cohesionless soils under varying drainage conditions. These drawbacks can affect the accuracy and representativeness of shear strength parameters derived from the test compared to those obtained from triaxial tests.

Advantages and Limitations of Triaxial Test

The triaxial test offers precise control of confining pressure, enabling simulation of in-situ stress conditions and providing detailed shear strength parameters under varied drainage conditions. It allows measurement of pore water pressure, critical for evaluating effective stress and soil behavior more accurately than the direct shear test. However, the triaxial test is more time-consuming, complex, and requires specialized equipment, which can increase cost and limit its practicality for routine site investigations.

Applications in Geological Engineering Projects

Direct shear tests provide rapid evaluation of soil shear strength parameters, crucial for assessing slope stability and foundation bearing capacity in geological engineering projects. Triaxial tests offer comprehensive data on soil behavior under controlled stress conditions, making them ideal for complex analyses like embankment design and earthquake-resistant structures. Combining results from both tests enhances the reliability of geotechnical investigations in diverse substrate conditions.

Selection Criteria: Choosing the Appropriate Test

Selection criteria for direct shear versus triaxial tests depend on soil type, stress conditions, and test objectives. Direct shear tests are preferred for quick, economical assessment of shear strength in coarse-grained soils under simple stress paths. Triaxial tests provide detailed strength parameters, effective stress analysis, and drainage conditions, making them suitable for cohesive soils and complex stress states.

Shear strength parameters

Direct shear tests measure shear strength parameters including cohesion (c) and internal friction angle (ph) under simple shear conditions, while triaxial tests provide more comprehensive shear strength parameters by simulating different drainage conditions and stress paths to evaluate effective stress parameters and failure envelopes.

Mohr-Coulomb failure criterion

The direct shear test determines soil shear strength along a predetermined plane under the Mohr-Coulomb criterion, while the triaxial test evaluates shear strength more comprehensively by measuring stress conditions in all directions to better define cohesion and internal friction angle parameters.

Confining pressure

Direct shear tests apply a constant normal load with no lateral confinement, whereas triaxial tests simulate in-situ soil conditions by applying controlled confining pressure around the specimen.

Drainage conditions

Direct shear tests are typically performed under drained conditions allowing pore water pressure dissipation, whereas triaxial tests can be conducted under both drained and undrained conditions to evaluate soil shear strength and pore pressure response.

Principal stresses

Direct shear tests apply shear stress along a single plane while triaxial tests measure principal stresses in three dimensions to analyze soil strength under simulated field conditions.

Pore water pressure

Direct shear tests measure shear strength without directly accounting for pore water pressure, while triaxial tests enable precise monitoring and control of pore water pressure to evaluate effective stress and soil behavior under saturated conditions.

Stress-strain behavior

The direct shear test exhibits a simpler stress-strain curve with a distinct peak shear strength and strain at failure, while the triaxial test provides a more comprehensive stress-strain behavior, capturing volumetric changes and allowing measurement of both shear strength and deformation under controlled confining pressure.

Sample anisotropy

Sample anisotropy significantly affects shear strength results in direct shear tests due to fixed shear planes, while triaxial tests provide more accurate strength measurements by allowing stress conditions to accommodate anisotropic sample behavior.

Normal stress application

Normal stress in direct shear tests is applied as a constant vertical load on the sample surface, whereas in triaxial tests, normal stress is applied isotropically through confining pressure using a fluid medium.

Failure envelope

The direct shear test produces a linear failure envelope representing shear strength at a fixed normal stress, while the triaxial test generates a more comprehensive failure envelope that accounts for varying confining pressures and better reflects soil strength under diverse stress conditions.

direct shear vs triaxial test Infographic

njnir.com

njnir.com