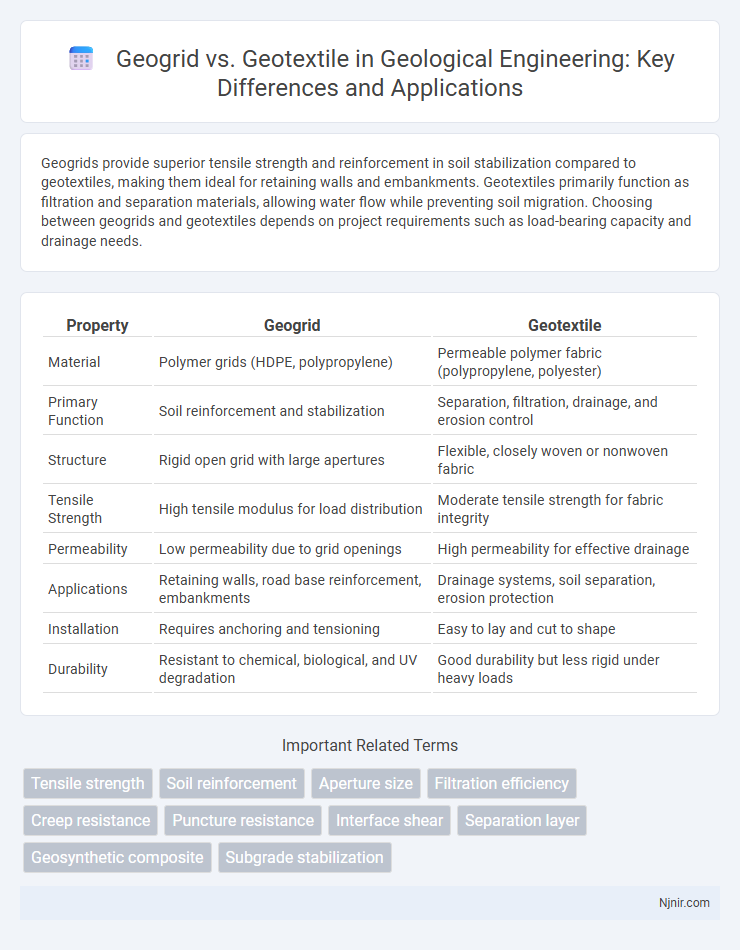

Geogrids provide superior tensile strength and reinforcement in soil stabilization compared to geotextiles, making them ideal for retaining walls and embankments. Geotextiles primarily function as filtration and separation materials, allowing water flow while preventing soil migration. Choosing between geogrids and geotextiles depends on project requirements such as load-bearing capacity and drainage needs.

Table of Comparison

| Property | Geogrid | Geotextile |

|---|---|---|

| Material | Polymer grids (HDPE, polypropylene) | Permeable polymer fabric (polypropylene, polyester) |

| Primary Function | Soil reinforcement and stabilization | Separation, filtration, drainage, and erosion control |

| Structure | Rigid open grid with large apertures | Flexible, closely woven or nonwoven fabric |

| Tensile Strength | High tensile modulus for load distribution | Moderate tensile strength for fabric integrity |

| Permeability | Low permeability due to grid openings | High permeability for effective drainage |

| Applications | Retaining walls, road base reinforcement, embankments | Drainage systems, soil separation, erosion protection |

| Installation | Requires anchoring and tensioning | Easy to lay and cut to shape |

| Durability | Resistant to chemical, biological, and UV degradation | Good durability but less rigid under heavy loads |

Introduction to Geogrids and Geotextiles

Geogrids are synthetic materials designed to reinforce soil by providing tensile strength and improving load distribution in construction and civil engineering projects. Geotextiles, made from permeable fabrics, facilitate soil stabilization, filtration, and separation by allowing water flow while preventing soil erosion. Both materials play essential roles in ground improvement, with geogrids primarily enhancing structural support and geotextiles optimizing soil-water interaction.

Material Composition: Geogrid vs Geotextile

Geogrids are primarily made from high-strength polymers such as polyethylene, polypropylene, or polyester, designed to provide tensile reinforcement and load distribution in soil stabilization projects. Geotextiles, on the other hand, consist of woven or non-woven fabrics made from synthetic fibers like polypropylene or polyester, optimized for filtration, separation, and drainage functions. The material composition differences directly influence their mechanical properties and application in civil engineering and geotechnical construction.

Structural Differences and Design

Geogrids feature a grid-like structure made from polymers such as polypropylene or polyester, providing high tensile strength and effective soil reinforcement by interlocking with surrounding materials. In contrast, geotextiles are permeable fabrics, woven or nonwoven, designed primarily for filtration, separation, and drainage rather than load bearing. The design of geogrids targets soil stabilization and load distribution in retaining walls, embankments, and pavements, whereas geotextiles enhance soil separation and fluid flow control without significant structural reinforcement.

Key Functions in Geological Engineering

Geogrids provide primary reinforcement by distributing loads and improving soil stability through interlocking with surrounding materials, making them ideal for retaining walls and slope stabilization. Geotextiles primarily function as separation, filtration, and drainage layers, preventing soil mixing and allowing fluid flow while maintaining soil structure. Both materials enhance soil performance but serve distinct roles in geological engineering applications based on their mechanical and hydraulic properties.

Installation Techniques: Geogrid vs Geotextile

Geogrid installation requires precise alignment and tensioning to ensure structural reinforcement in soil stabilization projects, often involving staking or anchoring at edges and overlaps. Geotextile installation involves unrolling fabric over prepared surfaces, with seams typically overlapped by 6 to 12 inches and secured using pins or staples to prevent displacement. Both materials demand proper site preparation and handling to maximize effectiveness in erosion control and soil separation applications.

Performance in Soil Stabilization

Geogrids exhibit superior tensile strength and stiffness compared to geotextiles, providing enhanced reinforcement and load distribution in soil stabilization projects. Their open grid structure allows for greater soil interlock and improved resistance to deformation under heavy loads. Geotextiles primarily function as filtration and separation layers, offering less structural support but effective soil erosion control and drainage.

Durability and Longevity Comparison

Geogrids typically offer higher durability and longevity compared to geotextiles due to their rigid polymeric structure, which resists deformation and maintains tensile strength under heavy loads. Geotextiles, primarily designed for filtration and separation, may degrade faster under UV exposure and mechanical stress, reducing their effective lifespan. Selecting geogrids in infrastructure projects enhances long-term performance in soil reinforcement, especially in high-stress environments.

Cost Analysis and Economic Considerations

Geogrids generally offer higher initial costs compared to geotextiles due to their complex manufacturing processes and robust load-bearing properties, making them a more capital-intensive choice for projects requiring soil stabilization and reinforcement. Geotextiles, being less expensive and easier to install, provide economical solutions for filtration, drainage, and separation, especially in applications with lower load demands. Long-term economic considerations favor geogrids in scenarios involving heavy traffic or extreme soil conditions due to their durability and enhanced structural benefits, which can reduce maintenance and replacement expenses over time.

Application Areas: Case Studies

Geogrids excel in applications requiring soil reinforcement, such as retaining walls, road construction, and slope stabilization, demonstrated by projects like highway embankments in Texas and railway track support in India. Geotextiles are predominantly used for filtration, separation, and drainage in civil engineering, evident in case studies involving highway drainage systems in Germany and erosion control in coastal areas of Australia. The choice between geogrid and geotextile in construction projects largely depends on site-specific requirements for load-bearing capacity and soil interaction.

Choosing Between Geogrid and Geotextile

Choosing between geogrid and geotextile depends on the specific soil stabilization and reinforcement needs of a project. Geogrids provide superior tensile strength and are ideal for load-bearing applications such as retaining walls and road bases, while geotextiles excel in filtration, separation, and drainage functions. Understanding the mechanical properties, environmental conditions, and project requirements ensures optimal material selection for enhanced structural performance.

Tensile strength

Geogrids exhibit significantly higher tensile strength than geotextiles, making them more effective for soil reinforcement and load-bearing applications.

Soil reinforcement

Geogrids provide superior soil reinforcement compared to geotextiles by offering higher tensile strength and improved load distribution for stabilizing soil in construction projects.

Aperture size

Geogrids feature larger, precisely engineered aperture sizes to enhance soil reinforcement and load distribution, while geotextiles have smaller, permeable apertures designed primarily for filtration and separation.

Filtration efficiency

Geotextiles demonstrate higher filtration efficiency than geogrids by effectively allowing water flow while retaining soil particles, making them superior for soil stabilization and erosion control applications.

Creep resistance

Geogrids exhibit superior creep resistance compared to geotextiles due to their higher tensile strength and lattice structure that effectively distributes loads over time.

Puncture resistance

Geogrids exhibit superior puncture resistance compared to geotextiles due to their rigid, grid-like structure that effectively distributes loads and prevents localized damage.

Interface shear

Geogrids provide superior interface shear strength compared to geotextiles, enhancing soil reinforcement and stability in civil engineering applications.

Separation layer

Geogrids provide superior tensile reinforcement and load distribution as a separation layer compared to geotextiles, which primarily offer filtration and minimal reinforcement.

Geosynthetic composite

Geosynthetic composites combine geogrids and geotextiles to enhance soil reinforcement, filtration, and drainage in civil engineering applications.

Subgrade stabilization

Geogrids provide superior subgrade stabilization by reinforcing soil with a high tensile strength grid structure, while geotextiles primarily offer filtration and separation without significant load-bearing reinforcement.

geogrid vs geotextile Infographic

njnir.com

njnir.com