Grouting involves injecting fluid materials into rock or soil to fill voids and enhance stability, making it ideal for ground improvement and seepage control. Shotcreting applies a pneumatically projected concrete layer onto surfaces, effectively reinforcing exposed rock faces or tunnel walls by providing immediate structural support. Both techniques are crucial in geological engineering, with grouting improving subsurface conditions and shotcreting strengthening surface stability.

Table of Comparison

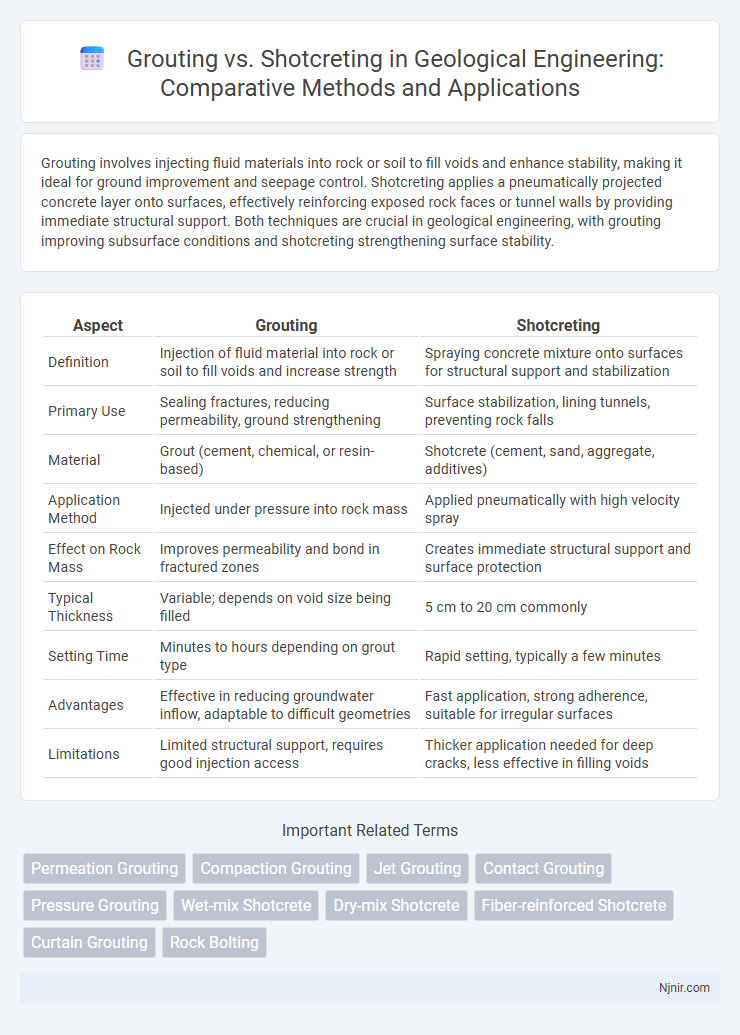

| Aspect | Grouting | Shotcreting |

|---|---|---|

| Definition | Injection of fluid material into rock or soil to fill voids and increase strength | Spraying concrete mixture onto surfaces for structural support and stabilization |

| Primary Use | Sealing fractures, reducing permeability, ground strengthening | Surface stabilization, lining tunnels, preventing rock falls |

| Material | Grout (cement, chemical, or resin-based) | Shotcrete (cement, sand, aggregate, additives) |

| Application Method | Injected under pressure into rock mass | Applied pneumatically with high velocity spray |

| Effect on Rock Mass | Improves permeability and bond in fractured zones | Creates immediate structural support and surface protection |

| Typical Thickness | Variable; depends on void size being filled | 5 cm to 20 cm commonly |

| Setting Time | Minutes to hours depending on grout type | Rapid setting, typically a few minutes |

| Advantages | Effective in reducing groundwater inflow, adaptable to difficult geometries | Fast application, strong adherence, suitable for irregular surfaces |

| Limitations | Limited structural support, requires good injection access | Thicker application needed for deep cracks, less effective in filling voids |

Introduction to Grouting and Shotcreting in Geological Engineering

Grouting in geological engineering involves injecting fluid materials, such as cement or chemical mixtures, into soil or rock formations to enhance stability, reduce permeability, and fill voids. Shotcreting, by contrast, applies a high-velocity spray of concrete or mortar onto surfaces, often used for ground support in tunnels and excavations to provide immediate structural reinforcement. Both techniques are critical in ground improvement and support, with grouting primarily addressing subsurface consolidation and shotcreting focusing on surface stabilization.

Definitions: What are Grouting and Shotcreting?

Grouting is a construction process involving the injection of fluid materials such as cement, chemical, or epoxy into cracks or voids to fill gaps and improve structural integrity. Shotcreting refers to the application of concrete or mortar projected at high velocity onto surfaces, providing both structural support and surface finishing. Both techniques enhance stability but differ in method and material application.

Key Differences Between Grouting and Shotcreting

Grouting involves injecting a fluid mixture of cement, water, and additives into voids or cracks to enhance structural stability and reduce permeability, primarily used in soil stabilization and sealing applications. Shotcreting is the process of spraying a pneumatically conveyed mortar or concrete mix onto a surface at high velocity, commonly employed for slope stabilization, tunnel linings, and structural repairs. Key differences include the application method--grouting fills voids internally while shotcreting creates a protective surface layer--and material consistency, with grouts being more fluid and shotcrete designed for rapid adhesion and strength development.

Materials Used in Grouting vs Shotcreting

Grouting typically uses cementitious, chemical, or resin-based materials that are fluid enough to penetrate fine voids and cracks, ensuring deep filling and stabilization of substrates. Shotcreting employs a mixture of cement, sand, water, and optional admixtures, sprayed pneumatically at high velocity to form a dense, cohesive layer ideal for structural reinforcement and surface protection. The choice of materials in shotcreting emphasizes rapid setting and bonding strength, whereas grouting materials prioritize flowability and permeability to fill voids effectively.

Application Techniques: Grouting and Shotcreting Methods

Grouting involves injecting fluid materials such as cement, chemical solutions, or resins into voids or cracks to enhance soil or rock stability, often using pressure pumps and injectors tailored to the substrate. Shotcreting applies pneumatically projected concrete or mortar mixtures onto surfaces with high velocity, utilizing specialized spraying equipment that ensures strong adhesion and compaction, ideal for structural reinforcement and slope stabilization. Both methods require precise control over material composition and delivery systems to optimize bonding, durability, and load-bearing capacity in construction and geotechnical engineering projects.

Engineering Purposes and Effectiveness

Grouting involves injecting fluid materials like cement or chemical mixtures into voids or cracks to enhance ground stability and reduce permeability, making it ideal for soil stabilization and structural repairs in engineering projects. Shotcreting uses pneumatically applied concrete to provide immediate surface support and reinforcement, particularly effective in tunneling, slope stabilization, and retaining wall construction. Both techniques improve structural integrity, but shotcreting offers rapid application with high compressive strength, while grouting ensures deep consolidation and sealing of subsurface defects.

Advantages and Disadvantages of Grouting

Grouting improves soil stability and fills voids effectively, offering precise control over material placement and minimal surface disturbance. Its disadvantages include potential environmental risks from chemical usage and slower curing times compared to shotcreting. Grouting is ideal for applications requiring deep soil consolidation and reduced structural loading, while shotcreting provides faster application and higher compressive strength for surface protection.

Pros and Cons of Shotcreting

Shotcreting offers high compressive strength and excellent adhesion to irregular surfaces, making it ideal for structural reinforcement and complex repairs. It allows for rapid application and curing, reducing downtime in construction projects. However, shotcreting requires skilled operators and specialized equipment, and improper application can lead to clogging or poor bonding, limiting its effectiveness in some conditions.

Selection Criteria: When to Use Grouting or Shotcreting

Grouting is ideal for filling voids, sealing cracks, and stabilizing soil or rock in confined spaces due to its fluid consistency and low-pressure application. Shotcreting is preferred for structural reinforcement and surface support in tunnels or slopes, offering rapid setting and high strength through pneumatically applied concrete. Selection criteria depend on project requirements such as load-bearing needs, accessibility, material properties, and desired curing time.

Case Studies and Real-World Applications

Case studies in tunnel construction reveal grouting effectively stabilizes soil and reduces water ingress by injecting cementitious or chemical mixtures into voids. Shotcreting finds extensive real-world application in slope stabilization and underground mining, providing immediate structural support with sprayed concrete that adheres to irregular surfaces. Comparative analyses demonstrate grouting suits permeable ground conditions, while shotcreting offers faster reinforcement in dynamic excavation environments.

Permeation Grouting

Permeation grouting involves injecting low-viscosity grout into soil pores to improve ground impermeability and strength, contrasting with shotcreting, which applies high-velocity concrete for surface stabilization.

Compaction Grouting

Compaction grouting improves soil density and stability by injecting stiff, low-mobility grout that displaces and compacts loose soils, whereas shotcreting involves spraying concrete for surface reinforcement without soil densification.

Jet Grouting

Jet grouting creates high-strength soilcrete by injecting high-pressure grout jets to improve ground stability, whereas traditional grouting fills voids and shotcreting applies sprayed concrete for surface support.

Contact Grouting

Contact grouting involves injecting cementitious material into voids between soil and structures to improve contact and load transfer, significantly enhancing the stability of foundations compared to shotcreting, which applies sprayed concrete for surface reinforcement.

Pressure Grouting

Pressure grouting involves injecting fluid grout under high pressure into soil or rock to improve stability and fill voids, whereas shotcreting sprays concrete pneumatically for structural reinforcement.

Wet-mix Shotcrete

Wet-mix shotcrete offers superior adhesion and reduced rebound compared to traditional grouting, making it ideal for structural repairs and complex surface applications.

Dry-mix Shotcrete

Dry-mix shotcrete offers precise water control and reduced rebound compared to grouting, making it ideal for applications requiring high-strength, rapid-setting concrete in complex structural repairs.

Fiber-reinforced Shotcrete

Fiber-reinforced shotcrete offers superior structural strength and crack resistance compared to traditional grouting due to its enhanced bonding properties and fiber integration.

Curtain Grouting

Curtain grouting enhances foundation stability by injecting permeable soil layers with grout to form a waterproof barrier, contrasting with shotcreting which applies sprayed concrete for surface reinforcement.

Rock Bolting

Shotcreting provides immediate rock surface support while grouting reinforces rock bolts by filling fractures, enhancing overall rock bolting stability.

grouting vs shotcreting Infographic

njnir.com

njnir.com