Tunnel boring machines (TBMs) provide precise excavation with minimal surface disruption and continuous operation, making them ideal for long, uniform tunnels in stable geological conditions. Drill and blast methods offer flexibility in varying rock types and complex alignments but generate vibrations and require extensive ground support. Selection depends on geological conditions, project scale, and cost considerations, balancing efficiency and safety in tunnel construction.

Table of Comparison

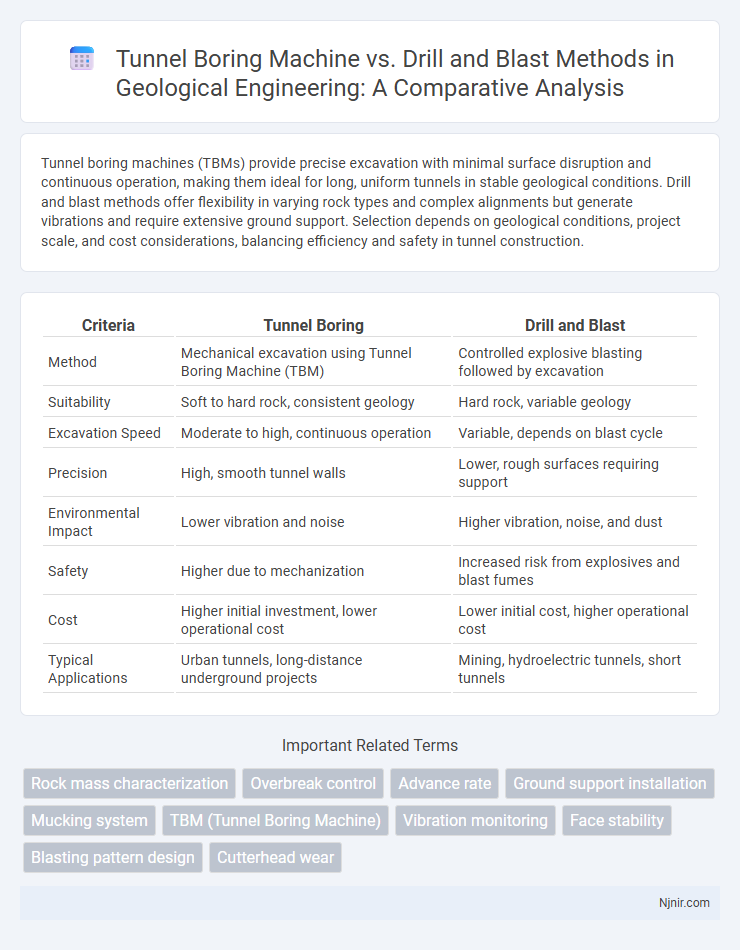

| Criteria | Tunnel Boring | Drill and Blast |

|---|---|---|

| Method | Mechanical excavation using Tunnel Boring Machine (TBM) | Controlled explosive blasting followed by excavation |

| Suitability | Soft to hard rock, consistent geology | Hard rock, variable geology |

| Excavation Speed | Moderate to high, continuous operation | Variable, depends on blast cycle |

| Precision | High, smooth tunnel walls | Lower, rough surfaces requiring support |

| Environmental Impact | Lower vibration and noise | Higher vibration, noise, and dust |

| Safety | Higher due to mechanization | Increased risk from explosives and blast fumes |

| Cost | Higher initial investment, lower operational cost | Lower initial cost, higher operational cost |

| Typical Applications | Urban tunnels, long-distance underground projects | Mining, hydroelectric tunnels, short tunnels |

Introduction to Tunnel Excavation Methods

Tunnel excavation methods primarily include tunnel boring and drill and blast techniques, each suited to specific geological conditions and project requirements. Tunnel boring machines (TBMs) offer a continuous, mechanized process ideal for uniform rock and soil, minimizing surface disruption and enhancing safety. Drill and blast relies on controlled explosives for breaking hard rock, allowing flexibility in complex or variable geology but often requiring longer excavation times and increased vibration management.

Tunnel Boring Machines: Principles and Applications

Tunnel Boring Machines (TBMs) operate using rotating cutter heads that excavate soil and rock while simultaneously installing tunnel support systems, enabling continuous and efficient tunneling in urban and varied geological conditions. TBMs are preferred over drill and blast methods due to their ability to minimize ground disturbance, reduce environmental impact, and enhance worker safety, especially in densely populated or sensitive areas. Their applications extend across subway construction, hydroelectric projects, and underground utilities, where precise tunnel alignment and smooth tunnel walls are critical.

Drill and Blast Technique: Process and Equipment

The drill and blast technique involves drilling holes into rock surfaces, followed by loading them with explosives to fracture the rock for removal. Equipment such as rotary drills, jumbo drills, and explosive cartridges are essential for creating precise blast patterns that optimize rock fragmentation and minimize environmental impact. This method is particularly effective in hard rock conditions and requires careful coordination to ensure safety and efficiency throughout the blasting process.

Geological Factors Influencing Excavation Method Selection

Geological factors such as rock type, hardness, and groundwater conditions critically influence the choice between tunnel boring and drill and blast methods. Tunnel boring machines (TBMs) excel in homogeneous, stable rock formations with minimal fractures, providing smoother tunnel walls and faster progress in such geological settings. In contrast, drill and blast are preferred in highly variable or hard rock conditions where TBMs may face operational difficulties due to frequent changes in rock geology or presence of abrasive materials.

Comparative Construction Speed: TBM vs Drill and Blast

Tunnel boring machines (TBMs) typically achieve faster construction speeds compared to drill and blast methods, producing continuous tunnel progress of up to 15-20 meters per day in favorable geological conditions. Drill and blast speeds vary significantly with rock type and safety considerations, often averaging 2-6 meters per day due to cyclic excavation and ventilation requirements. The consistent mechanized operation of TBMs minimizes downtime and material handling, enhancing overall project efficiency relative to the intermittent process of drilling, blasting, mucking, and support installation in drill and blast tunneling.

Cost Analysis: Initial Investment and Long-term Economics

Tunnel boring machines (TBMs) require a significantly higher initial investment, often ranging from $10 million to $100 million, due to the complexity and scale of the machinery. Drill and blast methods typically have lower upfront costs but incur higher long-term expenses related to slower progress, increased labor, and greater ground support requirements. Long-term economics favor TBMs in large, continuous tunnel projects because of faster excavation rates, reduced maintenance, and minimized ventilation costs compared to the intermittent and labor-intensive drill and blast technique.

Safety and Environmental Considerations

Tunnel boring machines (TBMs) generally offer enhanced safety by reducing the risk of rockfalls and minimizing worker exposure to hazardous dust and gases compared to drill and blast methods. Environmental impact is lower with TBMs due to reduced noise, vibration, and controlled spoil management, while drill and blast techniques often produce significant vibration, noise pollution, and handling of explosive materials that can harm nearby ecosystems. Strict ventilation systems and continuous monitoring in TBM operations further mitigate health risks, ensuring a safer and more environmentally sustainable tunneling process.

Tunnel Lining and Support Requirements

Tunnel boring machines (TBMs) produce smooth tunnel walls that often require immediate precast concrete segmental linings, enhancing structural integrity and water tightness. Drill and blast excavation results in more irregular tunnel profiles, necessitating flexible support systems such as shotcrete, rock bolts, and steel ribs before installing permanent linings. The choice between TBM and drill and blast methods significantly influences tunnel lining design and support requirements, affecting project cost and construction speed.

Case Studies: Notable TBM and Drill and Blast Projects

The Gotthard Base Tunnel in Switzerland exemplifies the success of tunnel boring machines (TBM), showcasing 57 km of continuous, precise excavation through challenging Alpine geology. In contrast, the Channel Tunnel connecting the UK and France employed both drill and blast techniques and TBM methods, highlighting flexibility in varying ground conditions. The Kariba Dam Tunnel in Zambia utilized drill and blast effectively to navigate complex hard rock formations, demonstrating its viability where TBM might be less efficient.

Future Trends in Tunnel Excavation Technology

Future trends in tunnel excavation technology emphasize automation and precision, with tunnel boring machines (TBMs) integrating AI-driven monitoring systems for enhanced efficiency and safety. Drill and blast methods are evolving through controlled blasting techniques and digital modeling to minimize environmental impact and optimize rock fragmentation. Hybrid approaches combining TBM advancements with selective drilling and blasting promise greater adaptability in complex geological conditions and urban tunneling projects.

Rock mass characterization

Rock mass characterization reveals that tunnel boring machines excel in uniform, stable rock formations, while drill and blast methods adapt better to heterogeneous, fractured rock conditions.

Overbreak control

Tunnel boring machines provide precise overbreak control by maintaining consistent tunnel profiles, whereas drill and blast methods often result in greater overbreak variability due to explosive-induced fractures.

Advance rate

Tunnel boring machines achieve advance rates of up to 15 meters per day in hard rock, significantly outperforming drill and blast methods, which typically advance 2 to 6 meters per day depending on rock conditions.

Ground support installation

Tunnel boring machines enable continuous ground support installation with minimal disturbance, whereas drill and blast methods require intermittent ground support due to cyclic blasting-induced ground instability.

Mucking system

The mucking system in tunnel boring machines offers continuous, automated debris removal enhancing operational efficiency, while drill and blast relies on intermittent, manual or semi-automated mucking methods that typically slow project progress.

TBM (Tunnel Boring Machine)

Tunnel Boring Machines (TBMs) offer faster excavation speeds, reduced ground disturbance, and enhanced safety compared to drill and blast methods, making them ideal for long, continuous tunnel projects in urban and sensitive environments.

Vibration monitoring

Tunnel boring generates lower and more consistent vibrations compared to drill and blast methods, making vibration monitoring critical for minimizing structural impact and ensuring safety in urban tunneling projects.

Face stability

Tunnel boring machines provide superior face stability compared to drill and blast methods by minimizing ground disturbance and allowing continuous support during excavation.

Blasting pattern design

Blasting pattern design in drill and blast tunneling optimizes explosive placement and timing for efficient rock fragmentation, while tunnel boring relies on continuous mechanical excavation without blasting patterns.

Cutterhead wear

Tunnel boring machines experience significantly less cutterhead wear compared to drill and blast methods due to continuous excavation and controlled pressure on cutting tools.

Tunnel boring vs Drill and blast Infographic

njnir.com

njnir.com