Shear strength in geological engineering is critical for assessing the stability of soil and rock masses, as it governs their ability to resist sliding along failure planes. Tensile strength, although generally lower in geomaterials, influences the formation of fractures and crack propagation within rock formations. Understanding the balance between shear and tensile strengths helps engineers design safer foundations, slopes, and underground excavations.

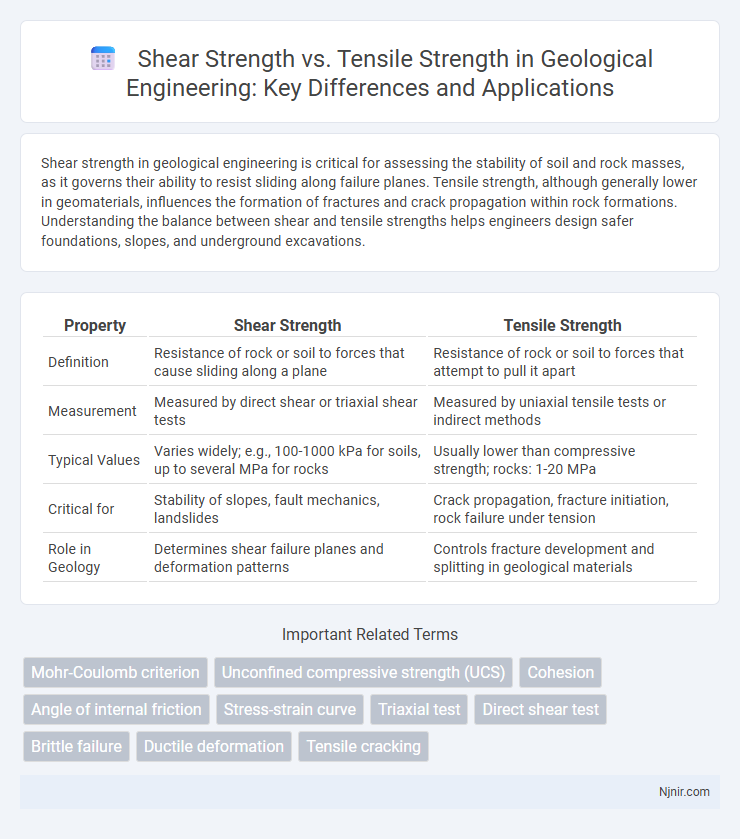

Table of Comparison

| Property | Shear Strength | Tensile Strength |

|---|---|---|

| Definition | Resistance of rock or soil to forces that cause sliding along a plane | Resistance of rock or soil to forces that attempt to pull it apart |

| Measurement | Measured by direct shear or triaxial shear tests | Measured by uniaxial tensile tests or indirect methods |

| Typical Values | Varies widely; e.g., 100-1000 kPa for soils, up to several MPa for rocks | Usually lower than compressive strength; rocks: 1-20 MPa |

| Critical for | Stability of slopes, fault mechanics, landslides | Crack propagation, fracture initiation, rock failure under tension |

| Role in Geology | Determines shear failure planes and deformation patterns | Controls fracture development and splitting in geological materials |

Introduction to Shear and Tensile Strength in Geological Engineering

Shear strength in geological engineering refers to a soil or rock's resistance to forces that cause sliding along internal planes, crucial for assessing slope stability and foundation design. Tensile strength measures a material's capacity to withstand pulling forces without fracturing, often lower in soils but vital for evaluating cracks and fissures. Understanding the distinction between shear and tensile strength aids engineers in predicting failure modes and designing safer geotechnical structures.

Defining Shear Strength: Concepts and Mechanisms

Shear strength refers to a material's ability to resist forces that cause sliding or deformation along a plane parallel to the force direction, typically measured in units of pressure such as megapascals (MPa). It primarily depends on the atomic or molecular bonds' resistance to displacement, reflecting mechanisms including grain boundary friction and dislocation movements within the material's microstructure. Unlike tensile strength, which measures resistance to pulling forces causing elongation, shear strength focuses on the internal cohesion resisting parallel shear stresses applied in applications like bolted joints or structural beams.

Understanding Tensile Strength in Geological Materials

Tensile strength in geological materials measures their ability to resist forces that attempt to pull them apart, reflecting the material's internal cohesion and fracture resistance. It is crucial for assessing rock stability in engineering and construction, as it typically registers lower values compared to compressive strength but higher than shear strength in most rocks. Accurate testing methods like direct tension tests and indirect methods such as Brazilian tests provide key data for modeling stress responses in geological formations.

Key Differences: Shear Strength vs Tensile Strength

Shear strength measures a material's ability to resist forces that cause layers to slide against each other, while tensile strength evaluates the maximum stress a material can endure when being stretched or pulled. Tensile strength is typically higher because it involves direct axial load, whereas shear strength relates to parallel opposing forces acting on a cross-sectional area. Understanding these differences is crucial for engineering applications that require selecting materials based on load direction and failure mode.

Factors Affecting Shear Strength in Geomaterials

Shear strength in geomaterials is primarily influenced by factors such as mineral composition, grain size, moisture content, and confining pressure, which directly affect particle interlocking and frictional resistance. The presence of clay minerals and water content significantly decrease shear strength due to reduced cohesion and increased pore water pressure. Tensile strength, although generally lower than shear strength in geomaterials, is less variable and depends mainly on the soil or rock's inherent tensile capacity and the presence of microfractures.

Influences on Tensile Strength in Rocks and Soils

Tensile strength in rocks and soils is primarily influenced by mineral composition, grain size, porosity, and moisture content, which collectively affect cohesion and structural integrity. Shear strength depends on internal friction and effective stress, but tensile strength is sensitive to tensile crack formation and propagation under stress. Environmental factors like weathering and saturation significantly reduce tensile strength by weakening bonds within the material's microstructure.

Laboratory Testing Methods for Shear and Tensile Strength

Laboratory testing methods for shear strength commonly involve direct shear tests, where a sample is subjected to a controlled horizontal force until failure occurs, accurately measuring the maximum shear stress the material can withstand. Tensile strength testing typically employs uniaxial tensile tests that stretch the specimen using a universal testing machine, recording the maximum stress before fracture. Both testing methods generate critical data used in material selection and structural design, ensuring components meet specific performance criteria under different loading conditions.

Practical Implications in Slope Stability and Foundation Design

Shear strength plays a crucial role in slope stability by resisting soil or rock failure along potential slip surfaces, directly influencing the factor of safety against landslides. In foundation design, tensile strength is typically limited in soils but essential in concrete and steel, determining the material's ability to withstand pulling forces without cracking. Understanding the balance between shear and tensile strengths ensures optimized designs that prevent structural failures and maintain ground stability under diverse loading conditions.

Case Studies Illustrating Failure Mechanisms

Case studies on material failure reveal that shear strength often dictates the initiation of cracks, especially in ductile metals where shear planes develop under stress, leading to localized deformation. In contrast, tensile strength failures typically involve the propagation of fractures perpendicular to the load axis, commonly observed in brittle materials such as ceramics and certain alloys under high tensile loads. These examples underscore the critical role of microstructural factors and stress distribution in determining whether shear or tensile failure dominates in engineering applications.

Advancements in Measuring and Enhancing Material Strength

Recent advancements in measuring shear strength and tensile strength leverage high-precision digital image correlation and acoustic emission techniques, enabling accurate real-time stress-strain analysis. Enhanced composite materials and nano-engineered alloys demonstrate significant improvements by optimizing microstructural properties, resulting in superior resistance to both shear and tensile forces. Integration of machine learning algorithms accelerates the design process, predicting material behavior under complex loading conditions with increasing accuracy.

Mohr-Coulomb criterion

The Mohr-Coulomb criterion defines shear strength as a function of tensile strength, cohesion, and internal friction angle, highlighting the material's failure under combined normal and shear stresses.

Unconfined compressive strength (UCS)

Unconfined compressive strength (UCS) is generally higher than shear strength and tensile strength in materials, serving as a key indicator of a soil or rock's ability to withstand axial loads without lateral confinement.

Cohesion

Cohesion significantly influences shear strength by enabling material particles to resist sliding past each other, whereas tensile strength primarily depends on the material's ability to withstand pulling forces without fracturing.

Angle of internal friction

The angle of internal friction significantly influences shear strength by enhancing resistance to sliding along particle interfaces, whereas tensile strength primarily depends on material cohesion without direct impact from this angle.

Stress-strain curve

Shear strength is typically lower than tensile strength and is represented by the peak stress on the shear stress-strain curve, while tensile strength corresponds to the maximum stress on the tensile stress-strain curve, both illustrating material behavior under different loading conditions.

Triaxial test

Triaxial test results reveal that tensile strength typically exceeds shear strength in soils due to the confining pressure enhancing shear resistance but having less impact on tensile failure.

Direct shear test

The direct shear test measures shear strength by applying a controlled horizontal force to a soil sample along a predefined failure plane, while tensile strength evaluates resistance to pulling forces, typically determined through separate tensile tests.

Brittle failure

Shear strength is typically lower than tensile strength in brittle materials, causing them to fail suddenly without significant plastic deformation under shear stress.

Ductile deformation

Ductile deformation exhibits higher tensile strength than shear strength due to the material's ability to plastically deform and absorb energy before failure.

Tensile cracking

Tensile cracking occurs when tensile strength is exceeded, causing materials to fracture along the direction of applied tensile stress, whereas shear strength resists sliding failure along planes parallel to the applied force.

shear strength vs tensile strength Infographic

njnir.com

njnir.com