Shotcrete provides immediate surface support by forming a protective layer that prevents rock spalling and weathering, making it ideal for stabilizing exposed rock faces. Rock bolts enhance structural integrity by anchoring unstable rock masses to more stable underlying layers, distributing stress over a larger area. Combining shotcrete and rock bolts optimizes tunnel and excavation stability by addressing both surface protection and deep reinforcement.

Table of Comparison

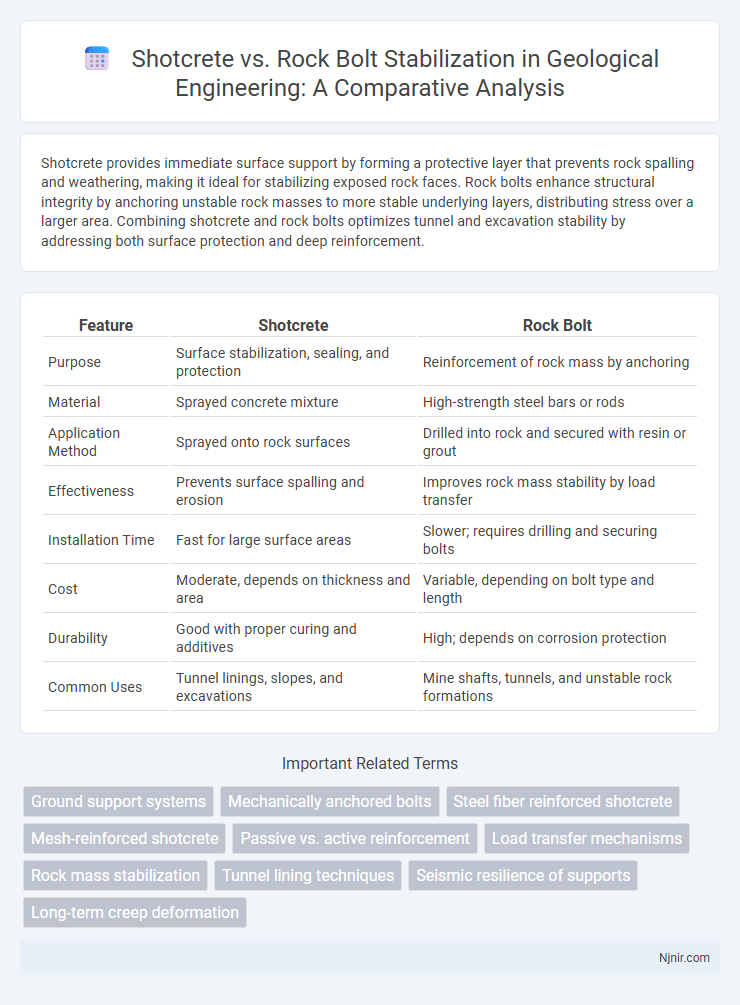

| Feature | Shotcrete | Rock Bolt |

|---|---|---|

| Purpose | Surface stabilization, sealing, and protection | Reinforcement of rock mass by anchoring |

| Material | Sprayed concrete mixture | High-strength steel bars or rods |

| Application Method | Sprayed onto rock surfaces | Drilled into rock and secured with resin or grout |

| Effectiveness | Prevents surface spalling and erosion | Improves rock mass stability by load transfer |

| Installation Time | Fast for large surface areas | Slower; requires drilling and securing bolts |

| Cost | Moderate, depends on thickness and area | Variable, depending on bolt type and length |

| Durability | Good with proper curing and additives | High; depends on corrosion protection |

| Common Uses | Tunnel linings, slopes, and excavations | Mine shafts, tunnels, and unstable rock formations |

Introduction to Ground Stabilization in Geological Engineering

Ground stabilization in geological engineering primarily employs shotcrete and rock bolt techniques to enhance slope and tunnel safety. Shotcrete, a sprayed concrete mixture, rapidly forms a protective shell over rock surfaces, preventing erosion and loose debris fall, while rock bolts physically anchor unstable rock masses by transferring load to more stable ground layers. Selecting between shotcrete and rock bolts depends on geological conditions, load requirements, and maintenance considerations, with combined use often optimizing structural integrity in challenging environments.

Overview of Shotcrete: Applications and Benefits

Shotcrete is a sprayed concrete technique widely applied in underground excavations, tunnel linings, and slope stabilization due to its rapid setting and strong adhesion properties. Its benefits include enhanced rock surface reinforcement, immediate load support, reduced excavation damage, and improved water resistance. Shotcrete minimizes installation time compared to traditional methods, making it a preferred solution for stabilizing unstable rock formations in mining and civil engineering projects.

Rock Bolts: Principles and Usage in Rock Reinforcement

Rock bolts stabilize rock masses by transferring load from the unstable outer layers to the stronger interior, reinforcing rock structures through tension or anchorage. Their installation involves drilling holes and inserting steel rods grouted or mechanically anchored to maintain rock integrity and prevent displacements. Commonly used in mining, tunneling, and slope stabilization, rock bolts enhance safety by providing controlled support where traditional methods like shotcrete may be less effective or require supplemental reinforcement.

Mechanisms of Rock Mass Stabilization: Shotcrete vs Rock Bolts

Shotcrete stabilizes rock masses by forming a continuous, load-distributing shell that prevents surface erosion and controls small-scale rock falls through tensile strength and adhesion. Rock bolts enhance stability by transferring load from the unstable rock surface to the stronger, deeper rock layers, creating a compressive force that binds discontinuities and increases overall shear strength. Combining shotcrete and rock bolts often optimizes rock mass stabilization by leveraging shotcrete's surface protection and rock bolts' internal reinforcement mechanisms.

Material Properties: Comparing Shotcrete and Rock Bolting Systems

Shotcrete offers high compressive strength and excellent adhesion to rock surfaces, making it ideal for immediate surface stabilization and impermeability. Rock bolts provide tensile reinforcement by anchoring into stable rock layers, effectively transferring load and controlling movement within rock masses. Combining shotcrete's surface support with rock bolts' deep anchorage optimizes overall ground stabilization in mining and tunneling applications.

Installation Techniques: Shotcrete Application vs Rock Bolt Installation

Shotcrete application involves spraying a high-velocity mixture of cement, sand, and water onto rock surfaces, creating an immediate, protective layer that conforms to irregular rock profiles. Rock bolt installation requires drilling precise holes into rock formations followed by inserting and securing steel bolts to reinforce and stabilize the rock mass internally. Shotcrete offers rapid surface coverage and sealing, while rock bolts provide deep anchorage and structural support, often used in combination for optimal ground stabilization.

Performance Evaluation: Load-Bearing Capacity and Durability

Shotcrete provides superior surface support with high load-bearing capacity due to its ability to conform to irregular rock surfaces and distribute stresses evenly. Rock bolts enhance structural integrity by reinforcing rock masses internally, offering long-term durability through mechanical anchoring and load transfer deep within the rock strata. Performance evaluations indicate that combining shotcrete and rock bolts often results in optimal stabilization by leveraging shotcrete's compressive strength and rock bolts' tensile reinforcement.

Cost Analysis: Economic Comparison of Shotcrete and Rock Bolts

Shotcrete generally incurs higher initial material and application costs compared to rock bolts, largely due to specialized equipment and labor requirements. Rock bolts offer a more cost-effective solution in stable ground conditions with quicker installation, reducing overall project expenses. Long-term economic considerations favor shotcrete in scenarios needing surface protection and structural reinforcement, where it minimizes maintenance and enhances durability.

Site-Specific Considerations for Method Selection

Site-specific considerations for shotcrete versus rock bolt stabilization hinge on geological conditions, excavation geometry, and anticipated load stresses, with shotcrete favored for irregular surfaces and immediate support, while rock bolts provide deep anchorage in stable rock masses. Soil composition, groundwater presence, and seismic activity influence method efficacy, as wet environments may reduce shotcrete adhesion whereas rock bolts perform consistently under dynamic loads. Cost, installation speed, and required maintenance also guide selection, emphasizing the need for thorough site investigation and geotechnical analysis to optimize stabilization strategy.

Future Trends and Innovations in Ground Support Technologies

Emerging trends in ground support technologies emphasize the integration of smart materials and real-time monitoring systems to enhance the effectiveness of shotcrete and rock bolt stabilization methods. Advances in fiber-reinforced shotcrete formulations improve durability and flexibility, while sensor-equipped rock bolts enable continuous stress and displacement measurements for proactive maintenance. Innovations like autonomous robotic application and machine learning analytics are set to revolutionize installation efficiency and safety in underground construction projects.

Ground support systems

Shotcrete provides immediate surface support by forming a rigid protective layer, while rock bolts reinforce ground stability by anchoring rock masses, making these systems complementary for effective ground support stabilization.

Mechanically anchored bolts

Mechanically anchored bolts in rock stabilization provide superior shear resistance and load transfer compared to shotcrete, making them more effective for reinforcing unstable rock masses in tunnel and slope support.

Steel fiber reinforced shotcrete

Steel fiber reinforced shotcrete enhances rock bolt stabilization by providing superior tensile strength, crack resistance, and improved load distribution compared to traditional shotcrete, leading to increased overall excavation support and durability.

Mesh-reinforced shotcrete

Mesh-reinforced shotcrete provides enhanced structural flexibility and crack control compared to rock bolt stabilization, making it ideal for securing unstable rock surfaces in tunneling and mining applications.

Passive vs. active reinforcement

Shotcrete provides passive reinforcement by encasing rock surfaces to prevent surface erosion, while rock bolts offer active reinforcement by transferring load and stabilizing rock masses through tensile anchoring.

Load transfer mechanisms

Shotcrete enhances load transfer through surface reinforcement by bonding to rock faces, while rock bolts transfer loads via axial tension and shear forces within the rock mass.

Rock mass stabilization

Rock mass stabilization with rock bolts provides enhanced structural integrity by anchoring unstable strata, promoting load transfer within the rock, and reducing displacement more effectively than shotcrete.

Tunnel lining techniques

Shotcrete offers rapid, flexible tunnel lining support through sprayed concrete application, while rock bolts provide targeted reinforcement by anchoring unstable rock strata, making their combined use essential for effective and durable tunnel stabilization.

Seismic resilience of supports

Shotcrete provides flexible surface support that absorbs seismic energy, while rock bolts enhance structural stability by anchoring unstable rock layers, together optimizing seismic resilience in ground support systems.

Long-term creep deformation

Shotcrete reduces long-term creep deformation in rock masses by providing immediate surface support and load distribution, whereas rock bolts primarily stabilize internal rock structure but may allow more gradual deformation over time.

shotcrete vs rock bolt stabilization Infographic

njnir.com

njnir.com