Shield tunneling offers precise ground support and minimizes surface disruption by using a mechanical shield to excavate and line tunnels simultaneously. Drill and blast tunneling relies on controlled explosives to fracture rock, which can cause vibrations and requires more extensive ground stabilization. Choosing between these methods depends on geological conditions, tunnel size, and environmental impact considerations.

Table of Comparison

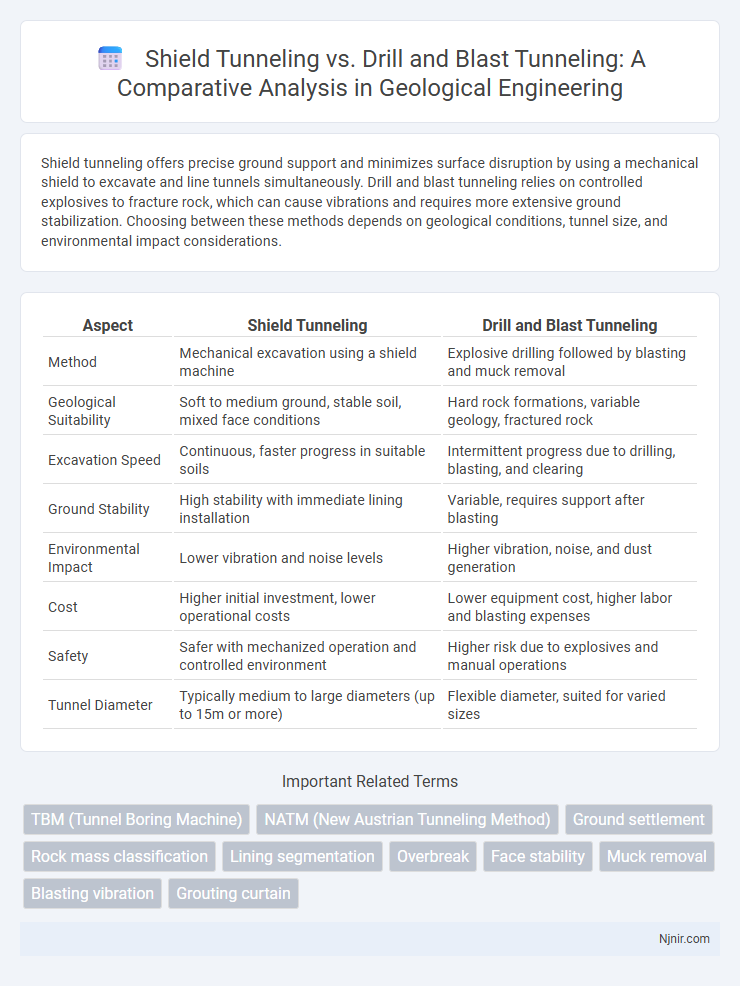

| Aspect | Shield Tunneling | Drill and Blast Tunneling |

|---|---|---|

| Method | Mechanical excavation using a shield machine | Explosive drilling followed by blasting and muck removal |

| Geological Suitability | Soft to medium ground, stable soil, mixed face conditions | Hard rock formations, variable geology, fractured rock |

| Excavation Speed | Continuous, faster progress in suitable soils | Intermittent progress due to drilling, blasting, and clearing |

| Ground Stability | High stability with immediate lining installation | Variable, requires support after blasting |

| Environmental Impact | Lower vibration and noise levels | Higher vibration, noise, and dust generation |

| Cost | Higher initial investment, lower operational costs | Lower equipment cost, higher labor and blasting expenses |

| Safety | Safer with mechanized operation and controlled environment | Higher risk due to explosives and manual operations |

| Tunnel Diameter | Typically medium to large diameters (up to 15m or more) | Flexible diameter, suited for varied sizes |

Introduction to Tunneling Methods in Geological Engineering

Shield tunneling involves the use of a mechanical shield to support the tunnel face and protect workers, making it ideal for soft, unstable ground with high groundwater conditions. Drill and blast tunneling employs controlled explosions to fracture hard rock, suitable for rigid geological formations but requiring extensive ventilation and support systems. Geological engineering must assess ground conditions, geological hazards, and excavation requirements to select the appropriate tunneling method, optimizing safety and efficiency.

Fundamentals of Shield Tunneling

Shield tunneling employs a cylindrical shield to support the excavation face, enabling continuous tunnel advancement in soft ground while minimizing surface settlement. The method integrates a cutting head, soil conditioning, and segmental lining installation, ensuring stability and safety throughout the process. Contrasting with drill and blast tunneling, shield tunneling offers precise control and reduced environmental impact, making it ideal for urban infrastructure projects.

Principles of Drill and Blast Tunneling

Drill and blast tunneling relies on a cyclic process involving drilling holes into rock, loading them with explosives, and detonating to fragment the rock for excavation. This method is effective for hard rock formations and allows for precise control over tunnel shape and size through controlled blasting patterns. The technique demands careful blast design and vibration management to ensure structural stability and minimize environmental impact.

Geological Conditions Favoring Shield Tunneling

Shield tunneling thrives in soft ground conditions such as clay, silt, and loose sand where stability and minimal surface settlement are critical. This method excels in urban areas with high groundwater levels, effectively managing water inflow and reducing ground disturbance. Hard rock and highly fractured formations are less suitable for shield tunneling, favoring drill and blast techniques instead.

Geological Suitability for Drill and Blast Tunneling

Drill and blast tunneling is most suitable for hard, massive rock formations such as granite, basalt, and gneiss where blasting can efficiently break the rock without causing excessive damage to the surrounding strata. This method is less effective in fractured, weak, or highly weathered geological conditions, where the risk of collapse and overbreak increases significantly. Geological suitability for drill and blast tunneling requires thorough geotechnical investigations to ensure competent rock mass and stable ground conditions for safe and efficient excavation.

Comparative Analysis of Construction Speed

Shield tunneling achieves faster construction speeds due to its mechanized process and continuous excavation, enabling simultaneous excavation and lining installation, which significantly reduces downtime. Drill and blast tunneling is slower as it involves sequential blasting, muck removal, ventilation, and support installation, causing frequent interruptions and longer cycle times. Project data shows shield tunneling can advance up to 15 meters per day, whereas drill and blast methods typically achieve 3 to 5 meters per day depending on geological conditions.

Cost Effectiveness: Shield vs Drill and Blast

Shield tunneling generally offers higher cost effectiveness in urban environments due to reduced excavation time and minimized surface disruption compared to drill and blast methods. Drill and blast tunneling, while often less expensive for hard rock conditions, incurs higher indirect costs from vibration control, muck removal, and extended project timelines. Project-specific factors such as geology, tunnel length, and environmental constraints ultimately influence the cost trade-offs between shield and drill and blast tunneling.

Safety Considerations in Tunneling Methods

Shield tunneling offers enhanced safety by providing continuous ground support and reducing exposure to unstable soil and rock conditions, minimizing risks like collapses and ground subsidence. Drill and blast tunneling involves controlled detonations that pose increased hazards such as flying debris, vibrations, and harmful gas emissions, requiring stringent safety protocols and ventilation systems. The choice between these methods heavily depends on site geology, with shield tunneling preferred in soft ground for its controlled environment and drill and blast suited for hard rock where mechanical excavation is less effective.

Environmental Impacts of Shield and Drill & Blast Tunneling

Shield tunneling significantly reduces environmental impacts by minimizing ground vibration, noise, and air pollution through its enclosed excavation method and continuous soil support, which limits soil displacement and groundwater disruption. In contrast, drill and blast tunneling generates higher levels of noise, vibration, and dust emissions, potentially causing greater disturbance to nearby ecosystems and structures. The choice between these methods directly influences the project's environmental footprint, with shield tunneling offering a more sustainable option for urban and ecologically sensitive areas.

Future Trends in Tunneling Technology

Future trends in tunneling technology emphasize automation and real-time monitoring, with shield tunneling advancing through enhanced TBM (Tunnel Boring Machine) automation and AI integration for precision and safety. Drill and blast tunneling is evolving by incorporating digital blast design software and vibration control technologies to minimize environmental impact and improve accuracy. Both methods are increasingly adopting sustainable practices and smart sensor systems to optimize performance and reduce operational costs.

TBM (Tunnel Boring Machine)

Tunnel Boring Machines (TBMs) offer precise, continuous excavation with minimal surface disruption in shield tunneling, contrasting with the intermittent, vibration-intensive drill and blast method best suited for hard rock conditions.

NATM (New Austrian Tunneling Method)

NATM, a flexible tunneling technique emphasizing controlled deformation and sequential excavation, contrasts with shield tunneling's mechanized support system and drill and blast's reliance on explosives for rock fragmentation.

Ground settlement

Shield tunneling minimizes ground settlement by providing continuous support to the tunnel face, whereas drill and blast tunneling typically causes greater ground displacement due to intermittent excavation and blasting vibrations.

Rock mass classification

Rock mass classification directly influences the choice between shield tunneling and drill and blast methods, as shield tunneling is optimal for homogeneous, stable rock types with high RMR or Q-values, whereas drill and blast is preferred for heterogeneous, fractured, or weak rock masses with lower classification scores.

Lining segmentation

Shield tunneling uses pre-cast, uniform lining segments for continuous support and watertightness, whereas drill and blast tunneling requires cast-in-place or irregular lining segments due to variable excavation profiles and unstable ground conditions.

Overbreak

Shield tunneling significantly reduces overbreak compared to drill and blast tunneling by providing continuous, controlled excavation support and minimizing rock disturbance.

Face stability

Shield tunneling provides superior face stability through continuous support and pressurized excavation, whereas drill and blast tunneling often risks face collapse due to intermittent excavation and lack of immediate support.

Muck removal

Shield tunneling optimizes muck removal through continuous conveyor systems, enhancing efficiency and reducing spoil handling time compared to the intermittent and labor-intensive muck removal in drill and blast tunneling.

Blasting vibration

Blasting vibration from drill and blast tunneling poses significant risks to surrounding structures, whereas shield tunneling minimizes ground disturbance and vibration impact.

Grouting curtain

The grouting curtain in shield tunneling provides more uniform ground stabilization and water control compared to the intermittent and less consistent grouting in drill and blast tunneling.

shield tunneling vs drill and blast tunneling Infographic

njnir.com

njnir.com