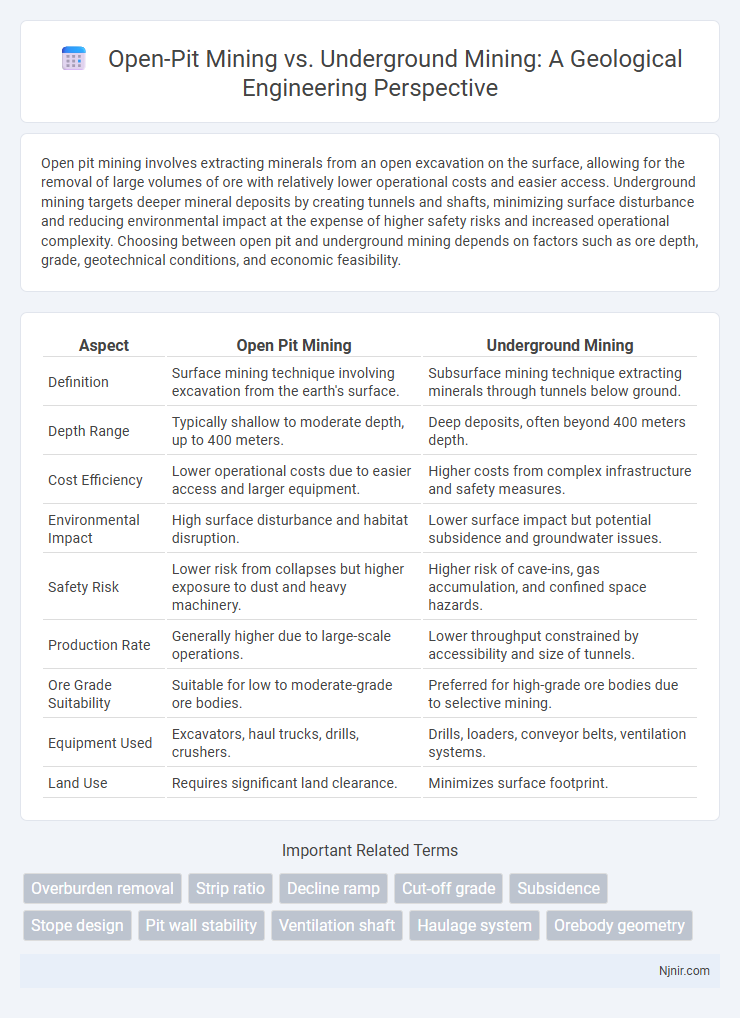

Open pit mining involves extracting minerals from an open excavation on the surface, allowing for the removal of large volumes of ore with relatively lower operational costs and easier access. Underground mining targets deeper mineral deposits by creating tunnels and shafts, minimizing surface disturbance and reducing environmental impact at the expense of higher safety risks and increased operational complexity. Choosing between open pit and underground mining depends on factors such as ore depth, grade, geotechnical conditions, and economic feasibility.

Table of Comparison

| Aspect | Open Pit Mining | Underground Mining |

|---|---|---|

| Definition | Surface mining technique involving excavation from the earth's surface. | Subsurface mining technique extracting minerals through tunnels below ground. |

| Depth Range | Typically shallow to moderate depth, up to 400 meters. | Deep deposits, often beyond 400 meters depth. |

| Cost Efficiency | Lower operational costs due to easier access and larger equipment. | Higher costs from complex infrastructure and safety measures. |

| Environmental Impact | High surface disturbance and habitat disruption. | Lower surface impact but potential subsidence and groundwater issues. |

| Safety Risk | Lower risk from collapses but higher exposure to dust and heavy machinery. | Higher risk of cave-ins, gas accumulation, and confined space hazards. |

| Production Rate | Generally higher due to large-scale operations. | Lower throughput constrained by accessibility and size of tunnels. |

| Ore Grade Suitability | Suitable for low to moderate-grade ore bodies. | Preferred for high-grade ore bodies due to selective mining. |

| Equipment Used | Excavators, haul trucks, drills, crushers. | Drills, loaders, conveyor belts, ventilation systems. |

| Land Use | Requires significant land clearance. | Minimizes surface footprint. |

Overview of Open Pit and Underground Mining

Open pit mining involves extracting minerals from an open excavation on the surface, enabling access to large, near-surface ore deposits with high efficiency and lower operational costs. Underground mining accesses deeper mineral resources through tunnels or shafts, allowing extraction of high-grade ore with minimal surface disturbance but higher safety risks and costs. Both methods require specific geological assessments and equipment tailored to ore body depth, grade, and environmental considerations.

Geological Considerations for Mining Method Selection

Open pit mining is preferred when ore bodies are close to the surface and cover large, relatively horizontal areas, allowing cost-effective extraction with minimal geological complexity. Underground mining is suitable for deep, steeply dipping ore bodies requiring precise geological mapping and structural stability assessment to prevent collapses. The choice depends on ore depth, deposit geometry, rock strength, and groundwater conditions, ensuring optimal safety and economic efficiency.

Cost Analysis: Open Pit vs Underground Mining

Open pit mining typically offers lower operational costs per ton due to the use of large-scale machinery and higher production rates, making it economically viable for near-surface ore deposits. Underground mining incurs higher costs stemming from complex ventilation, safety requirements, and labor intensity, which increase expenses in deep ore extraction. Cost efficiency between the two methods depends heavily on ore grade, deposit depth, and production scale, with open pit favored for shallow, large-scale mining and underground mining preferred for deeper, higher-grade deposits.

Environmental Impact Comparison

Open pit mining generates significant surface disturbance, leading to habitat destruction, soil erosion, and increased dust and noise pollution, while underground mining generally has a smaller surface footprint but risks subsidence and groundwater contamination. Waste rock and tailings from open pits often cause acid mine drainage, severely impacting local water quality, whereas underground mining produces less waste rock but poses challenges in managing underground water infiltration. Both methods require careful environmental management, but open pit mining typically results in more extensive ecosystem disruption and longer-term landscape alteration compared to underground mining.

Safety Challenges in Open Pit and Underground Mining

Open pit mining faces safety challenges such as slope instability, rockfalls, and exposure to weather conditions, which can lead to hazardous working environments for operators and equipment. In contrast, underground mining poses risks including confined spaces, ventilation issues, gas buildup, and potential tunnel collapses, requiring robust monitoring and emergency response systems. Effective safety management in both mining types depends on specialized training, real-time hazard detection technologies, and rigorous compliance with safety regulations.

Ore Recovery and Grade Control

Open pit mining generally achieves higher ore recovery rates due to the ability to extract large volumes of ore with less dilution, while underground mining offers more precise grade control by accessing ore bodies selectively and minimizing waste extraction. Grade control in underground mining utilizes detailed drilling and sampling techniques to maintain ore quality, whereas open pit mining relies on block modeling and blasting patterns to balance ore recovery and dilution. Both methods require advanced geological modeling and real-time data analysis to optimize ore recovery and maintain consistent grade control throughout the mining process.

Equipment and Technology Requirements

Open pit mining requires large-scale machinery such as hydraulic shovels, haul trucks with high payload capacity, and powerful drilling rigs designed for surface excavation. Underground mining demands specialized equipment like continuous miners, longwall shearers, ventilation systems, and remote-controlled loaders capable of operating in confined and hazardous environments. Advanced technology integration including real-time monitoring, automation, and ventilation control systems is critical in underground mining to ensure safety and operational efficiency.

Mine Planning and Design Differences

Open pit mining involves large-scale excavation with extensive surface stripping, requiring mine planning to optimize pit size, slope angles, and haul road layout for efficient ore extraction and waste removal. Underground mining demands precise design of access tunnels, shafts, and ventilation systems to ensure worker safety and maximize ore recovery while minimizing ground subsidence. The contrasting mine planning approaches focus on balancing operational costs, extraction efficiency, and environmental impact specific to each mining method.

Economic Lifespan and Resource Utilization

Open pit mining generally offers a longer economic lifespan due to its ability to process large volumes of ore at lower extraction costs, maximizing resource utilization near the surface. Underground mining, although having a shorter economic lifespan, enables access to deeper and higher-grade ore bodies, improving recovery rates of valuable minerals. Efficient resource utilization in open pit mining depends on stripping ratios, while underground methods prioritize selective extraction to optimize profitability and maintain ore quality.

Future Trends in Mining Methods

Future trends in mining methods emphasize automation and sustainability, with open pit mining increasingly integrating autonomous trucks and drones to enhance efficiency and reduce environmental impact. Underground mining is advancing through remote-controlled equipment and enhanced ventilation systems that improve worker safety and operational precision. Both methods are adopting digital twin technology and AI-driven predictive maintenance to optimize resource extraction and minimize costs.

Overburden removal

Open pit mining involves extensive overburden removal using heavy machinery to access ore near the surface, whereas underground mining minimizes overburden removal by creating tunnels and shafts below the surface.

Strip ratio

Open pit mining typically has a lower strip ratio than underground mining, making it more cost-effective for extracting near-surface ore deposits.

Decline ramp

Decline ramps in underground mining provide efficient access for equipment and personnel, contrasting with open pit mining's surface excavation methods that eliminate the need for such underground passageways.

Cut-off grade

Cut-off grade in open pit mining is typically higher due to lower operational costs and easier access, whereas underground mining generally requires a lower cut-off grade to justify the higher extraction expenses and limited accessibility.

Subsidence

Open pit mining generally causes less subsidence compared to underground mining, which frequently leads to significant ground surface collapse due to the removal of subterranean support.

Stope design

Stope design in open pit mining prioritizes large-scale, cost-efficient benching to maximize ore extraction, while underground mining focuses on precise, confined stope optimization to ensure safety and minimize ground control risks.

Pit wall stability

Open pit mining faces greater challenges in pit wall stability due to large exposed slopes requiring extensive geotechnical monitoring compared to the confined excavation environment of underground mining.

Ventilation shaft

Open pit mining typically requires fewer ventilation shafts due to open-air exposure, whereas underground mining depends heavily on strategically placed ventilation shafts to ensure air quality and worker safety.

Haulage system

Open pit mining utilizes conveyor belts and truck haulage systems for transporting large volumes of material over short distances, while underground mining relies on rail cars or shuttle trucks optimized for confined spaces and steep gradients.

Orebody geometry

Open pit mining is most efficient for large, near-surface orebodies with broad, shallow geometries, whereas underground mining is preferred for deep, narrow, and irregularly shaped orebodies requiring precise extraction.

open pit mining vs underground mining Infographic

njnir.com

njnir.com