Boreholes and wells serve distinct purposes in geological engineering, with boreholes primarily used for subsurface exploration and soil sampling, while wells are designed to extract groundwater. Boreholes are typically narrower and drilled to collect geological data, such as rock formations and groundwater levels, whereas wells are constructed wider to facilitate water flow and long-term extraction. Understanding the differences between borehole and well design is crucial for effective site investigation and sustainable water resource management.

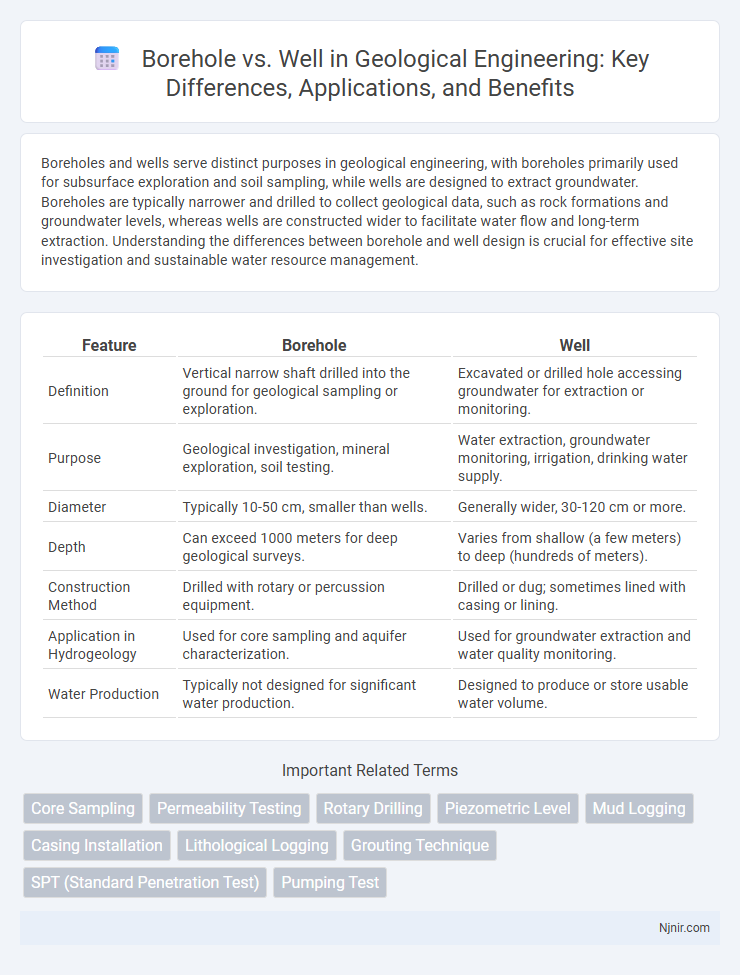

Table of Comparison

| Feature | Borehole | Well |

|---|---|---|

| Definition | Vertical narrow shaft drilled into the ground for geological sampling or exploration. | Excavated or drilled hole accessing groundwater for extraction or monitoring. |

| Purpose | Geological investigation, mineral exploration, soil testing. | Water extraction, groundwater monitoring, irrigation, drinking water supply. |

| Diameter | Typically 10-50 cm, smaller than wells. | Generally wider, 30-120 cm or more. |

| Depth | Can exceed 1000 meters for deep geological surveys. | Varies from shallow (a few meters) to deep (hundreds of meters). |

| Construction Method | Drilled with rotary or percussion equipment. | Drilled or dug; sometimes lined with casing or lining. |

| Application in Hydrogeology | Used for core sampling and aquifer characterization. | Used for groundwater extraction and water quality monitoring. |

| Water Production | Typically not designed for significant water production. | Designed to produce or store usable water volume. |

Introduction to Boreholes and Wells in Geological Engineering

Boreholes and wells serve distinct purposes in geological engineering, with boreholes primarily designed for subsurface investigation and data collection, such as soil sampling and groundwater monitoring. Wells are constructed for water extraction, often featuring larger diameters and casing to sustain water flow and prevent contamination. Understanding the differences in design, depth, and function is crucial for accurate geological assessment and resource management.

Definitions: Borehole vs Well

A borehole is a narrow, deep hole drilled into the ground primarily for exploration, extraction of minerals, or geological studies, often lined with casing to prevent collapse. A well, by contrast, is a natural or artificially dug shaft constructed to access groundwater for domestic, agricultural, or industrial use, typically wider and designed for water extraction. Boreholes tend to be more precise and engineered for specific purposes, while wells focus on sustainable water access.

Geological Purposes of Boreholes and Wells

Boreholes provide precise geological data by enabling direct sampling of subsurface layers, essential for mineral exploration and groundwater assessment. Wells primarily serve as water extraction points but also offer geological insights through lithological logging and monitoring of aquifer properties. The depth and diameter of boreholes allow detailed stratigraphic analysis, while wells typically balance geological investigation with resource accessibility.

Design and Construction Differences

Boreholes are narrow, deep, and drilled using rotary or percussion methods, designed primarily for groundwater extraction or monitoring, while wells are typically wider, excavated manually or mechanically, allowing easier access for water collection. The construction of boreholes involves casing and grouting to prevent collapse and contamination, whereas wells often use lining or simply rely on the surrounding earth for structural support. Boreholes generally reach greater depths with more precise drilling technology, contrasting wells which may be shallower and less technically complex.

Drilling Techniques and Equipment

Borehole drilling utilizes rotary or percussion techniques with specialized rigs such as reverse circulation or diamond core drills, designed for precise depth and diameter control in geological exploration. Wells often employ cable tool or rotary drilling methods, using rigs adapted for water extraction purposes, prioritizing durability and flow efficiency over core sampling accuracy. Equipment differences include borehole drills featuring advanced sensors for subsurface analysis, while well drilling rigs emphasize casing installation and pump integration to ensure long-term water supply stability.

Depth, Diameter, and Structural Variations

Boreholes typically have smaller diameters, ranging from 4 to 12 inches, and can reach depths up to several thousand feet, designed for precise applications like geological exploration or water extraction in confined aquifers. Wells generally have larger diameters, often exceeding 12 inches, and depths that vary widely depending on water table levels, constructed to provide access to groundwater for domestic, agricultural, or industrial use. Structurally, boreholes are narrow and lined with steel casings to prevent collapse, while wells may include broader structural elements such as reinforced concrete or masonry to ensure stability and facilitate maintenance.

Water Extraction and Resource Assessment

Boreholes provide targeted water extraction by penetrating deep aquifers with narrow, precisely drilled shafts, allowing for efficient access to confined groundwater sources. Wells typically tap into shallower, unconfined aquifers with wider openings, facilitating higher flow rates but greater susceptibility to contamination. Resource assessment for boreholes involves detailed hydrogeological surveys and flow testing to evaluate sustainable yield, while well assessment emphasizes surface water interaction and seasonal recharge variations.

Environmental Impact Considerations

Boreholes typically have a smaller environmental footprint compared to traditional wells due to their narrower diameter and reduced surface disturbance, minimizing habitat disruption and soil erosion. However, improper borehole construction or sealing can lead to groundwater contamination, similar to poorly maintained wells, highlighting the importance of strict regulatory standards for both. Sustainable water extraction from either boreholes or wells requires careful assessment of local aquifer recharge rates to prevent depletion and long-term ecological damage.

Maintenance and Longevity Factors

Boreholes require regular monitoring and cleaning to prevent silt buildup and maintain water flow, with casing inspections essential for preventing collapse and contamination. Wells benefit from routine wellhead maintenance and periodic well rehabilitation to ensure structural integrity and water quality over time. Longevity of both depends on proper sealing, quality of construction materials, and effective management of aquifer recharge to sustain water availability.

Choosing Between Boreholes and Wells in Geological Projects

Selecting between boreholes and wells in geological projects depends on factors such as depth, purpose, and geological conditions. Boreholes provide precise subsurface access for sampling and monitoring, typically reaching greater depths with smaller diameters, while wells are usually larger, designed for water extraction, and easier to maintain. Geological projects requiring detailed core samples or contamination assessments often favor boreholes, whereas wells are preferred for groundwater supply and irrigation needs.

Core Sampling

Core sampling in boreholes provides continuous, undisturbed geological data crucial for accurate subsurface analysis, unlike traditional wells that typically offer limited or discontinuous samples.

Permeability Testing

Permeability testing in boreholes provides precise subsurface hydraulic conductivity measurements essential for groundwater flow analysis, whereas wells primarily serve extraction without detailed permeability evaluation.

Rotary Drilling

Rotary drilling efficiently creates boreholes by rotating a drill bit to penetrate deep underground, distinguishing it from traditional well-digging methods that often rely on manual excavation.

Piezometric Level

The piezometric level in boreholes provides a precise measurement of groundwater pressure head, offering more accurate data than traditional wells for hydrogeological assessments.

Mud Logging

Mud logging in boreholes provides detailed geological data and real-time monitoring, while wells primarily serve as extraction points with limited logging capabilities.

Casing Installation

Borehole casing installation involves inserting steel or PVC pipes into drilled holes to prevent collapse and contamination, whereas well casing typically requires thicker, sealed pipes designed to protect water quality and maintain structural integrity in groundwater extraction.

Lithological Logging

Lithological logging in boreholes provides detailed subsurface geological profiles essential for accurate stratigraphic correlation and resource evaluation, whereas wells typically prioritize fluid extraction over comprehensive lithological documentation.

Grouting Technique

Grouting technique in boreholes involves sealing annular spaces with cement or bentonite to prevent contamination and enhance stability, whereas wells typically use simpler sealing methods focused on surface protection.

SPT (Standard Penetration Test)

Boreholes often utilize the Standard Penetration Test (SPT) to assess soil resistance and stratification at specific depths, whereas wells primarily focus on water extraction and typically do not incorporate SPT for geotechnical analysis.

Pumping Test

Pumping tests in boreholes provide detailed aquifer properties and yield data, offering more precise groundwater evaluation than traditional wells.

borehole vs well Infographic

njnir.com

njnir.com