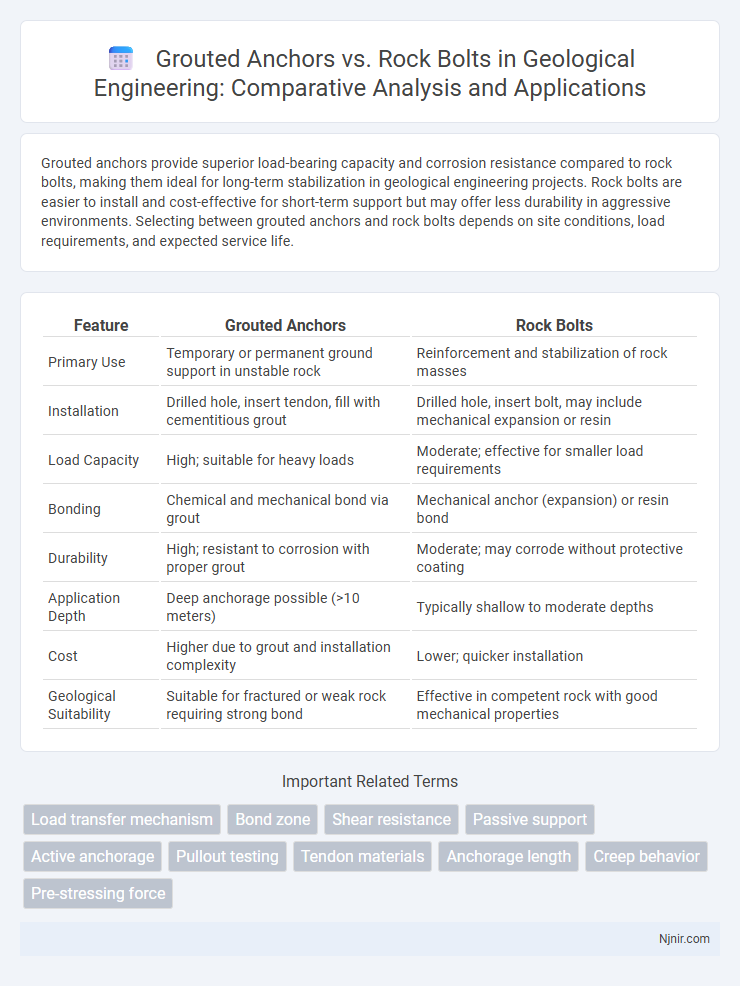

Grouted anchors provide superior load-bearing capacity and corrosion resistance compared to rock bolts, making them ideal for long-term stabilization in geological engineering projects. Rock bolts are easier to install and cost-effective for short-term support but may offer less durability in aggressive environments. Selecting between grouted anchors and rock bolts depends on site conditions, load requirements, and expected service life.

Table of Comparison

| Feature | Grouted Anchors | Rock Bolts |

|---|---|---|

| Primary Use | Temporary or permanent ground support in unstable rock | Reinforcement and stabilization of rock masses |

| Installation | Drilled hole, insert tendon, fill with cementitious grout | Drilled hole, insert bolt, may include mechanical expansion or resin |

| Load Capacity | High; suitable for heavy loads | Moderate; effective for smaller load requirements |

| Bonding | Chemical and mechanical bond via grout | Mechanical anchor (expansion) or resin bond |

| Durability | High; resistant to corrosion with proper grout | Moderate; may corrode without protective coating |

| Application Depth | Deep anchorage possible (>10 meters) | Typically shallow to moderate depths |

| Cost | Higher due to grout and installation complexity | Lower; quicker installation |

| Geological Suitability | Suitable for fractured or weak rock requiring strong bond | Effective in competent rock with good mechanical properties |

Introduction to Grouted Anchors and Rock Bolts

Grouted anchors consist of steel rods embedded in a drilled hole filled with high-strength grout, providing strong, permanent load-bearing capacity in rock or soil stabilization. Rock bolts are mechanical fasteners installed into rock formations, either tensioned or untensioned, to enhance structural integrity by binding rock layers. Both methods are essential in geotechnical engineering for improving slope stability, tunnel support, and foundation reinforcement.

Fundamental Principles and Mechanics

Grouted anchors rely on cementitious grout to bond the steel tendon to the surrounding rock or concrete, providing load transfer through chemical adhesion and mechanical interlock within the borehole. Rock bolts generally depend on frictional resistance created by the bolt expansion against the rock or by tensioning the bolt to compress the rock mass, stabilizing the structure through reinforcement and confinement. Both systems aim to enhance rock mass integrity, but grouted anchors offer higher load capacity and long-term durability by fully encapsulating the tendon in grout.

Materials and Construction Techniques

Grouted anchors use high-strength steel tendons encapsulated in cement-based grout, providing enhanced corrosion protection and load transfer in concrete or rock substrates. Rock bolts typically consist of steel rods or bars, often ungrouted or partially grouted, relying on mechanical interlock or friction with the rock for stabilization. Construction of grouted anchors involves drilling a hole, inserting the tendon, and grouting to fill voids, while rock bolts are installed by drilling, inserting the bolt, and either tensioning or resin anchoring depending on the geological conditions.

Load Transfer Mechanisms

Grouted anchors transfer load primarily through bond adhesion between the grout and surrounding rock, ensuring stability by developing tensile strength within the grout medium. Rock bolts rely on both frictional resistance and mechanical interlock with the rock mass, distributing load through bearing pressure along the bolt-rock interface. The efficiency of load transfer in grouted anchors depends on grout quality and annular contact, whereas rock bolts require proper tensioning to optimize load distribution and minimize slippage.

Design Standards and Specifications

Grouted anchors and rock bolts are governed by distinct design standards such as ASTM D7692 for grouted anchors and ASTM D4435 for rock bolts, ensuring specific load-bearing criteria and installation procedures. Grouted anchors require detailed specifications on grout composition and bond length to optimize load transfer, while rock bolt design emphasizes bolt length and diameter to accommodate rock mass conditions and shear forces. Compliance with standards like FHWA NHI-14-020 for grouted anchors and ISRM Suggested Methods for rock bolts ensures structural integrity and safety in geotechnical applications.

Comparative Installation Methods

Grouted anchors involve drilling a hole, inserting a steel tendon, and filling it with cementitious grout to bond the anchor permanently within the rock mass, providing high load capacity and corrosion protection. Rock bolts typically consist of steel bars installed by drilling and either mechanically or resin anchored into the rock, offering quicker installation but generally lower bond strength and durability compared to grouted anchors. The grouting process requires careful mixing and curing time, while rock bolts can be set rapidly, making the choice dependent on project duration, rock condition, and load requirements.

Performance in Various Geological Conditions

Grouted anchors provide superior load-bearing capacity and corrosion resistance in fractured and weathered rock formations compared to rock bolts, making them ideal for unstable geological conditions. Rock bolts excel in competent, intact rock by offering quick installation and immediate support, but their effectiveness diminishes in highly fractured or loose ground where grouted anchors create a more reliable bond. Performance varies significantly with geology, as grouted anchors distribute stress over a larger rock volume, enhancing stability in complex structures while rock bolts remain cost-effective for simpler, uniform rock masses.

Durability and Long-Term Monitoring

Grouted anchors provide superior durability compared to rock bolts due to their corrosion-resistant grout and full-length bonding with the rock mass, ensuring long-term stability in harsh environments. Rock bolts rely on mechanical interlock and may be susceptible to corrosion without protective coatings, which can compromise their structural integrity over time. Long-term monitoring of grouted anchors often shows consistent load transfer and minimal displacement, whereas rock bolts may require more frequent inspections and maintenance to detect early signs of degradation.

Cost-Effectiveness Analysis

Grouted anchors often provide superior load capacity and corrosion resistance compared to rock bolts, resulting in longer service life and lower maintenance costs for infrastructure projects. Initial installation costs for rock bolts are typically lower, but their lower durability and limited load-bearing capacity can lead to higher lifecycle expenses in demanding geotechnical conditions. Evaluating project-specific factors such as ground conditions, load requirements, and expected lifespan is essential for determining the most cost-effective anchoring solution.

Application Case Studies and Best Practices

Grouted anchors excel in stabilizing large-scale retaining walls and tunnels where high load capacity and durability are critical, with case studies highlighting their effectiveness in seismic zones and deep excavation projects. Rock bolts are preferred for reinforcing rock masses in mining and underground construction, proven by field applications that demonstrate improved rock mass integrity and reduced movement in brittle geological conditions. Best practices recommend selecting grouted anchors for long-term stabilization under dynamic loads and favoring rock bolts for rapid installation in stable rock formations, ensuring tailored reinforcement strategies based on site-specific geotechnical assessments.

Load transfer mechanism

Grouted anchors transfer load through bond strength between the grout, rock, and steel, while rock bolts primarily rely on mechanical interlocking and friction within rock fractures for load transfer.

Bond zone

Grouted anchors create a stronger and more durable bond zone by filling fractures and voids with cement grout, whereas rock bolts primarily rely on mechanical interlock within rock fissures resulting in a less consistent bond strength.

Shear resistance

Grouted anchors provide higher shear resistance than rock bolts due to better load transfer through full encapsulation and improved bonding with surrounding rock.

Passive support

Grouted anchors provide enhanced passive support by transferring load through bonded grout interaction with rock, offering superior stability compared to rock bolts that primarily rely on frictional resistance.

Active anchorage

Active anchorage with grouted anchors provides superior load transfer and corrosion protection compared to rock bolts, enhancing long-term stability in rock reinforcement.

Pullout testing

Pullout testing of grouted anchors shows higher load capacity and reduced displacement compared to rock bolts due to improved bond strength between the grout and surrounding rock.

Tendon materials

Grouted anchors typically use corrosion-resistant steel tendons with high tensile strength for long-term stability, while rock bolts often employ galvanized or stainless steel tendons designed for immediate load transfer and surface reinforcement.

Anchorage length

Grouted anchors typically require longer anchorage lengths than rock bolts to achieve optimal load transfer and stability in rock reinforcement.

Creep behavior

Grouted anchors exhibit lower creep deformation compared to rock bolts due to improved load transfer and adhesion within the grout-rock interface.

Pre-stressing force

Grouted anchors provide higher pre-stressing force capacity and better load transfer in rock stabilization compared to rock bolts due to their bonded length and grout encapsulation.

Grouted anchors vs Rock bolts Infographic

njnir.com

njnir.com