Tailings dams are engineered structures designed specifically to store mining waste materials, often requiring careful management of chemical stability and seepage control due to the hazardous nature of the stored tailings. Embankment dams, constructed primarily from natural materials like earth or rockfill, focus on water retention and structural stability under variable hydrological conditions. The difference lies in their purpose, material composition, and the environmental risks they pose, with tailings dams demanding specialized monitoring to prevent contamination and embankment dams emphasizing hydraulic integrity and erosion resistance.

Table of Comparison

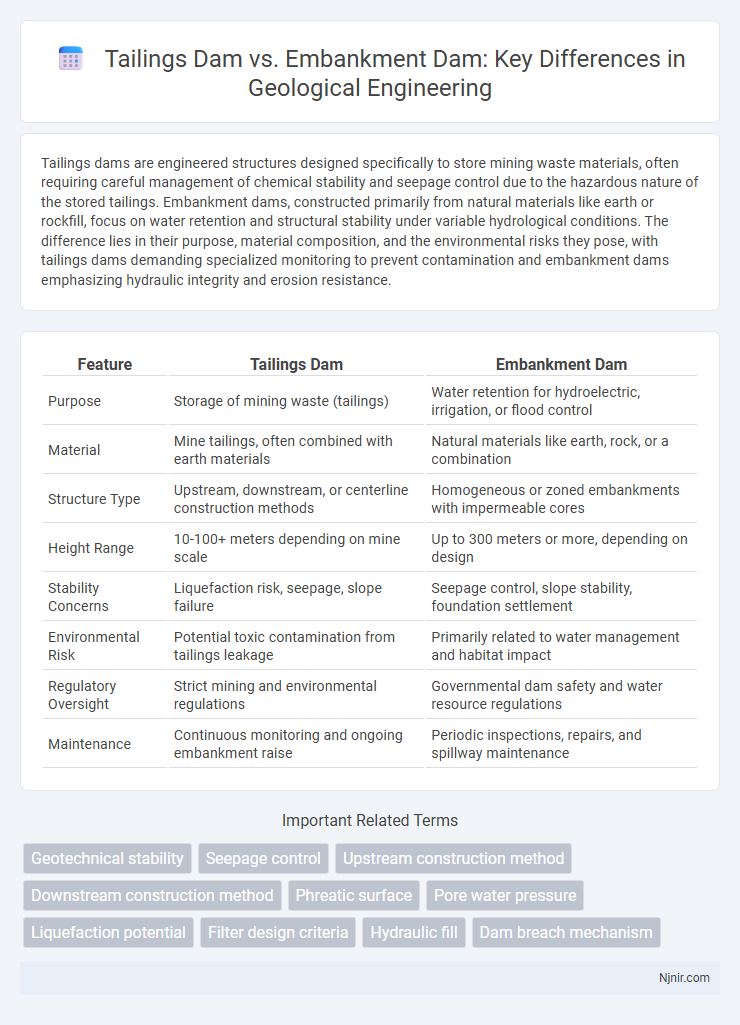

| Feature | Tailings Dam | Embankment Dam |

|---|---|---|

| Purpose | Storage of mining waste (tailings) | Water retention for hydroelectric, irrigation, or flood control |

| Material | Mine tailings, often combined with earth materials | Natural materials like earth, rock, or a combination |

| Structure Type | Upstream, downstream, or centerline construction methods | Homogeneous or zoned embankments with impermeable cores |

| Height Range | 10-100+ meters depending on mine scale | Up to 300 meters or more, depending on design |

| Stability Concerns | Liquefaction risk, seepage, slope failure | Seepage control, slope stability, foundation settlement |

| Environmental Risk | Potential toxic contamination from tailings leakage | Primarily related to water management and habitat impact |

| Regulatory Oversight | Strict mining and environmental regulations | Governmental dam safety and water resource regulations |

| Maintenance | Continuous monitoring and ongoing embankment raise | Periodic inspections, repairs, and spillway maintenance |

Introduction to Tailings Dam and Embankment Dam

Tailings dams are engineered structures designed to store byproducts of mining operations, primarily composed of fine-grained waste materials and water mixtures. Embankment dams are large earth- or rock-filled barriers constructed to retain water for purposes such as irrigation, hydroelectric power, and flood control. Both dam types utilize compacted earth materials, but tailings dams prioritize settling and containment of mining waste, whereas embankment dams focus on structural stability and water retention.

Geological Considerations in Dam Construction

Tailings dams require careful geological assessments to ensure stable foundations in often variable and weak soils contaminated with mining byproducts, posing higher seepage and slope stability risks. Embankment dams rely on strong, well-compacted natural materials and geological formations to provide structural integrity and minimize settlement issues. Understanding local geology, including soil permeability, fault lines, and seismic activity, is critical for both dam types to prevent catastrophic failures and optimize long-term performance.

Structural Design Differences

Tailings dams are designed primarily to safely contain fine-grained mining waste materials with a focus on staged construction and flexibility to accommodate ongoing deposition, whereas embankment dams are engineered for water retention with emphasis on long-term structural stability under hydrostatic pressure. Tailings dams often utilize upstream, downstream, or centerline construction methods tailored to the geotechnical properties of the tailings, while embankment dams typically employ zoned or homogeneous fill materials arranged to resist seepage and erosion. Unlike embankment dams that prioritize impermeable cores and spillway integration, tailings dams require continuous monitoring and adaptive reinforcement due to variable tailings consolidation and potential for differential settlement.

Materials Used: Tailings vs Conventional Fill

Tailings dams primarily utilize mine tailings as the core material, which are fine-grained waste residues from mineral processing, often saturated and less stable compared to conventional fill. Embankment dams employ engineered fills such as compacted earth, rock, or gravel, designed for optimal strength, permeability, and durability. The material properties directly influence the structural integrity and long-term stability of each dam type, with tailings requiring specialized monitoring due to higher susceptibility to liquefaction and seepage.

Construction Methods and Techniques

Tailings dams are constructed using upstream, downstream, or centerline methods, relying heavily on the deposition of mining waste materials to form successive embankments, which necessitates careful control of moisture content and consolidation to ensure stability. Embankment dams typically utilize compacted earth or rockfill materials, built in layers with precise compaction and drainage systems, employing techniques such as zone construction to optimize strength and seepage resistance. Construction of tailings dams demands continuous monitoring and adaptive design due to ongoing deposition of tailings, contrasting with the more static, planned construction process of embankment dams aimed at water retention.

Environmental Risks and Impacts

Tailings dams pose significant environmental risks due to the potential release of toxic mining byproducts, including heavy metals and chemical contaminants, which can lead to soil, water, and ecosystem pollution. Embankment dams, while generally safer in terms of chemical hazards, can cause substantial habitat disruption, sedimentation issues, and altered water flow patterns that affect downstream aquatic ecosystems. Both types demand rigorous monitoring and maintenance to mitigate the impacts of structural failure, which can result in catastrophic environmental damage.

Stability and Failure Mechanisms

Tailings dams primarily face stability challenges due to saturated fine-grained materials leading to seepage-induced softening and piezometric pressures, whereas embankment dams encounter risks from heterogeneous soil compaction and differential settlement. Failure mechanisms in tailings dams often involve liquefaction and static liquefaction triggered by earthquakes or rapid drawdowns, while embankment dams typically fail due to slope instability, internal erosion (piping), or overtopping erosion. Monitoring pore water pressure and slope movements is critical for both types, but tailings dams demand enhanced geotechnical controls due to their depositional nature and variable tailings properties.

Monitoring and Maintenance Practices

Tailings dams require continuous and rigorous monitoring to detect signs of instability caused by the presence of fine particulate waste and varying water levels, often using piezometers, inclinometers, and automated remote sensing technologies. Embankment dams, constructed primarily from natural materials like earth and rock, rely on regular visual inspections, seepage measurements, and structural evaluations to prevent erosion and settlement issues. Both types of dams benefit from integrated maintenance practices that include real-time data analysis and prompt repair interventions to ensure long-term structural integrity and environmental safety.

Regulatory Standards and Best Practices

Tailings dams require stringent regulatory standards focused on environmental protection, stability monitoring, and risk management due to their containment of mining waste, with regulations often mandating frequent inspections, emergency response planning, and community safety protocols. Embankment dams, primarily built for water storage, follow well-established engineering guidelines emphasizing structural integrity, seepage control, and flood management, governed by agencies like the US Army Corps of Engineers or the International Commission on Large Dams (ICOLD). Best practices for tailings dams involve comprehensive geotechnical evaluations and progressive reclamation plans, whereas embankment dams prioritize detailed hydrological assessments and routine maintenance schedules to ensure long-term reliability.

Future Trends in Dam Engineering

Future trends in dam engineering emphasize the integration of smart monitoring technologies and advanced materials to enhance the safety and sustainability of tailings dams compared to traditional embankment dams. Innovations such as real-time sensor networks and geotechnical data analytics improve risk assessment and failure prediction, addressing the environmental challenges unique to mining waste containment. Sustainable embankment dam designs increasingly incorporate eco-friendly materials and adaptive structures to mitigate climate change impacts and ensure long-term operational resilience.

Geotechnical stability

Tailings dams exhibit lower geotechnical stability than embankment dams due to their construction from unconsolidated mine waste materials, requiring specialized engineering to manage seepage and settlement risks.

Seepage control

Seepage control in tailings dams primarily involves engineered drainage systems and impermeable liners to prevent toxic leachate migration, whereas embankment dams use compacted soil cores and cutoff walls to minimize water seepage and ensure structural stability.

Upstream construction method

The upstream construction method for tailings dams involves raising the dam by placing subsequent embankments on the consolidated tailings beach, offering cost-efficiency but increased risk of instability compared to embankment dams built with downstream or centerline methods.

Downstream construction method

The downstream construction method for tailings dams involves progressively building embankments downstream using compacted tailings materials, enhancing stability and reducing seepage compared to conventional embankment dams.

Phreatic surface

The phreatic surface in a tailings dam is critically monitored to prevent seepage and instability due to its saturated tailings material, whereas in an embankment dam, it influences pore water pressure within the compacted soil layers to ensure structural stability.

Pore water pressure

Tailings dams experience higher and more variable pore water pressure due to fine-grained, low-permeability materials, whereas embankment dams typically maintain more stable pore water pressure because of well-graded, compacted soils.

Liquefaction potential

Tailings dams exhibit higher liquefaction potential compared to embankment dams due to the fine-grained, saturated nature of tailings materials which reduces soil stability under seismic loading.

Filter design criteria

Filter design criteria for tailings dams prioritize fine-grained soils with high permeability to prevent migration of tailings particles, whereas embankment dam filters emphasize graded materials and zone compaction to control seepage and maintain structural stability.

Hydraulic fill

Hydraulic fill in tailings dams involves pumping slurry to form embankments that efficiently contain mining waste, whereas embankment dams use compacted earth or rock fill to create stable barriers for water storage.

Dam breach mechanism

Tailings dam breaches primarily occur due to liquefaction induced by saturation and weak tailings shear strength, whereas embankment dam failures often result from piping and internal erosion caused by seepage through the dam body.

Tailings dam vs Embankment dam Infographic

njnir.com

njnir.com