Shear strength and compressive strength are critical parameters in geological engineering that influence soil and rock stability. Shear strength governs the material's resistance to sliding failure along planes, while compressive strength measures its ability to withstand axial loads without crushing. Understanding the interaction between these strengths is essential for designing foundations, slopes, and retaining structures in geotechnical projects.

Table of Comparison

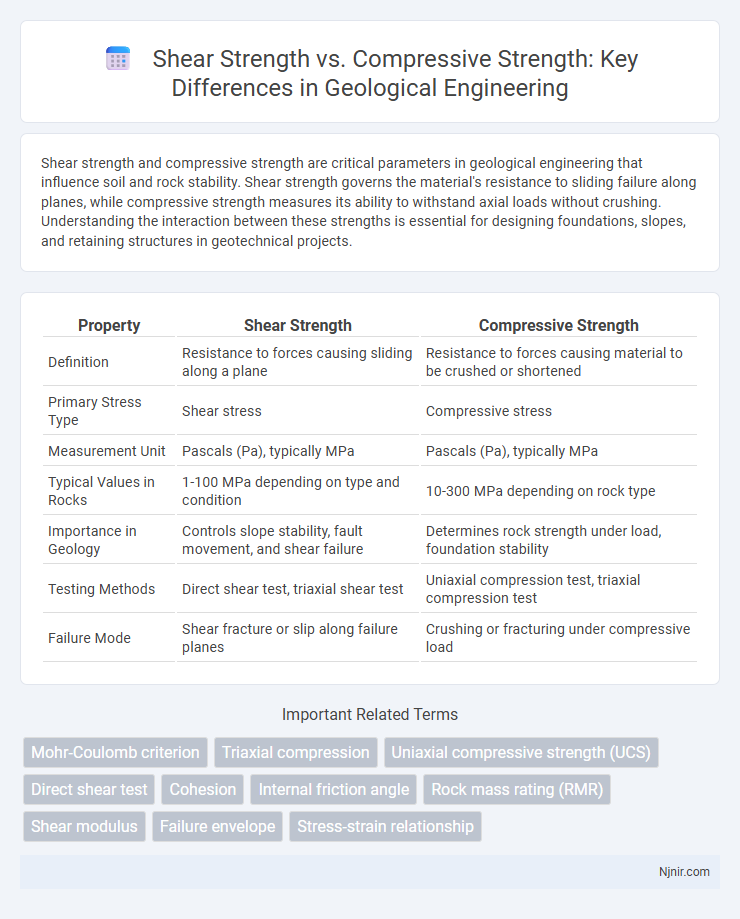

| Property | Shear Strength | Compressive Strength |

|---|---|---|

| Definition | Resistance to forces causing sliding along a plane | Resistance to forces causing material to be crushed or shortened |

| Primary Stress Type | Shear stress | Compressive stress |

| Measurement Unit | Pascals (Pa), typically MPa | Pascals (Pa), typically MPa |

| Typical Values in Rocks | 1-100 MPa depending on type and condition | 10-300 MPa depending on rock type |

| Importance in Geology | Controls slope stability, fault movement, and shear failure | Determines rock strength under load, foundation stability |

| Testing Methods | Direct shear test, triaxial shear test | Uniaxial compression test, triaxial compression test |

| Failure Mode | Shear fracture or slip along failure planes | Crushing or fracturing under compressive load |

Introduction to Shear Strength and Compressive Strength

Shear strength measures a material's ability to resist forces that cause layers to slide against each other, critical in structural and geotechnical engineering. Compressive strength evaluates how much load a material can withstand when being pressed or squeezed, essential for concrete, metals, and rocks in construction applications. Understanding both properties is vital for designing safe and durable structures that endure varied stress conditions.

Fundamental Definitions and Differences

Shear strength refers to the maximum stress a material can withstand parallel to its surface before failure, primarily resisting forces that cause layers to slide past each other. Compressive strength measures a material's ability to withstand axial loads that attempt to reduce its size, resisting forces that push inward and shorten the material. The fundamental difference lies in their stress orientations: shear strength involves tangential or sliding stress, while compressive strength involves normal or perpendicular stress.

Importance in Geological Engineering Applications

Shear strength is crucial in geological engineering for assessing slope stability, foundation design, and the integrity of soil and rock masses under lateral stress conditions. Compressive strength plays a vital role in evaluating the bearing capacity of soils and rocks, influencing the design of underground structures, tunnels, and retaining walls. Both strengths are essential for predicting failure mechanisms and ensuring the safety and durability of geotechnical projects.

Key Factors Influencing Shear Strength

Shear strength is primarily influenced by factors such as material composition, grain size, moisture content, and the presence of micro-cracks, while compressive strength depends largely on density and porosity. The internal friction angle and cohesion of materials significantly impact shear strength, with higher values leading to increased resistance against sliding or shearing forces. Environmental conditions like temperature and loading rate also play critical roles in defining the shear strength of structural materials.

Determinants of Compressive Strength in Geological Materials

Compressive strength in geological materials is primarily influenced by mineral composition, grain size, porosity, and moisture content, which collectively determine the material's ability to withstand axial loads. The cementation quality between grains and the presence of fissures or micro-cracks significantly affect the resistance to compressive forces. Temperature and pressure history during rock formation also play crucial roles in enhancing or reducing compressive strength by altering the internal structure and bonding mechanisms.

Laboratory Testing Methods for Shear and Compressive Strength

Laboratory testing methods for shear strength commonly involve direct shear tests, triaxial shear tests, and torsion shear tests, which measure soil or material resistance to sliding along a failure plane under controlled stress conditions. Compressive strength is typically evaluated through uniaxial or triaxial compression tests, determining the maximum load a material can bear before failure under axial stress. Both tests utilize standardized equipment and procedures, such as ASTM D3080 for direct shear and ASTM D2166 for unconfined compressive strength, ensuring reliable assessment of material mechanical properties.

Typical Values in Common Rock and Soil Types

Typical shear strength values for common soils range from 20 to 150 kPa in clays and up to 400 kPa in dense sands, while compressive strength in rocks varies widely from 1 MPa in soft sedimentary rocks to over 250 MPa in hard igneous and metamorphic rocks. In soils, shear strength depends heavily on cohesion and internal friction angle, whereas compressive strength in rocks correlates with mineral composition and porosity. These strength parameters are critical for geotechnical design, influencing slope stability, foundation bearing capacity, and excavation safety.

Role in Slope Stability and Foundation Design

Shear strength is critical for slope stability as it determines the soil's resistance to sliding along potential failure planes, directly influencing the angle of repose and the factor of safety against landslides. Compressive strength dictates the load-bearing capacity of foundation materials, ensuring structures can withstand vertical stresses without excessive settlement or failure. Accurate assessment of both shear and compressive strengths is essential for designing stable slopes and foundations that prevent structural damage and ground deformation.

Case Studies: Failure Mechanisms and Strength Comparison

Case studies reveal that shear strength often governs failure mechanisms in materials subjected to lateral loads, whereas compressive strength dominates under axial loads. For example, concrete beams frequently fail due to shear cracks despite high compressive strength, highlighting the critical role of shear strength in structural design. Comparative analyses of steel and concrete demonstrate that optimizing both shear and compressive strengths can enhance overall material performance and prevent premature failure.

Advances in Predicting and Enhancing Strength Properties

Advances in predicting shear and compressive strength leverage machine learning algorithms and high-resolution imaging techniques to analyze microstructural features influencing material behavior. Innovative composite materials with engineered fiber orientations improve shear strength without compromising compressive capacity, enhancing overall structural performance. Integration of nanoscale additives, such as carbon nanotubes, demonstrates significant potential in augmenting both shear and compressive strength by modifying interfacial bonding and crack propagation resistance.

Mohr-Coulomb criterion

The Mohr-Coulomb criterion defines shear strength as a function of compressive strength, cohesion, and internal friction angle, accurately predicting failure in materials under combined shear and normal stresses.

Triaxial compression

Triaxial compression tests reveal that compressive strength typically exceeds shear strength due to confining pressure enhancing material resistance.

Uniaxial compressive strength (UCS)

Uniaxial compressive strength (UCS) measures a material's maximum resistance to axial compressive loading, typically exceeding its shear strength, which quantifies resistance to sliding failure along a plane.

Direct shear test

The direct shear test measures shear strength by applying horizontal force to a soil sample along a predefined plane, providing critical data for evaluating soil stability under shear stress compared to its compressive strength.

Cohesion

Cohesion significantly influences shear strength by enabling materials to resist sliding along internal surfaces, whereas compressive strength primarily measures a material's ability to withstand axial loads without failure.

Internal friction angle

Shear strength depends on both cohesion and the internal friction angle, which significantly influences the material's resistance to shear stress compared to its compressive strength.

Rock mass rating (RMR)

Rock Mass Rating (RMR) integrates shear strength and compressive strength parameters to evaluate rock stability and support design in geotechnical engineering.

Shear modulus

Shear modulus quantifies a material's resistance to shear deformation, directly influencing shear strength but typically remaining independent of compressive strength, which measures resistance to axial loads.

Failure envelope

The failure envelope illustrates the relationship between shear strength and compressive strength, defining the stress combinations at which materials fail under varying shear and compressive loads.

Stress-strain relationship

Shear strength and compressive strength describe material resistance under different stress states, where shear strength relates to deformation along planes causing sliding failure, and compressive strength characterizes resistance to axial loads causing volumetric strain and material crushing, both quantified through their distinct stress-strain relationships reflecting elastic and plastic deformation behaviors.

Shear strength vs Compressive strength Infographic

njnir.com

njnir.com