Grouting involves injecting fluid materials into soil or rock to improve stability and reduce permeability, making it ideal for sealing fractures and voids. Anchoring entails installing rods or cables into rock or concrete to provide mechanical support and resist tension forces in slopes or structures. Both techniques enhance ground stability, but grouting primarily modifies ground properties while anchoring provides direct structural reinforcement.

Table of Comparison

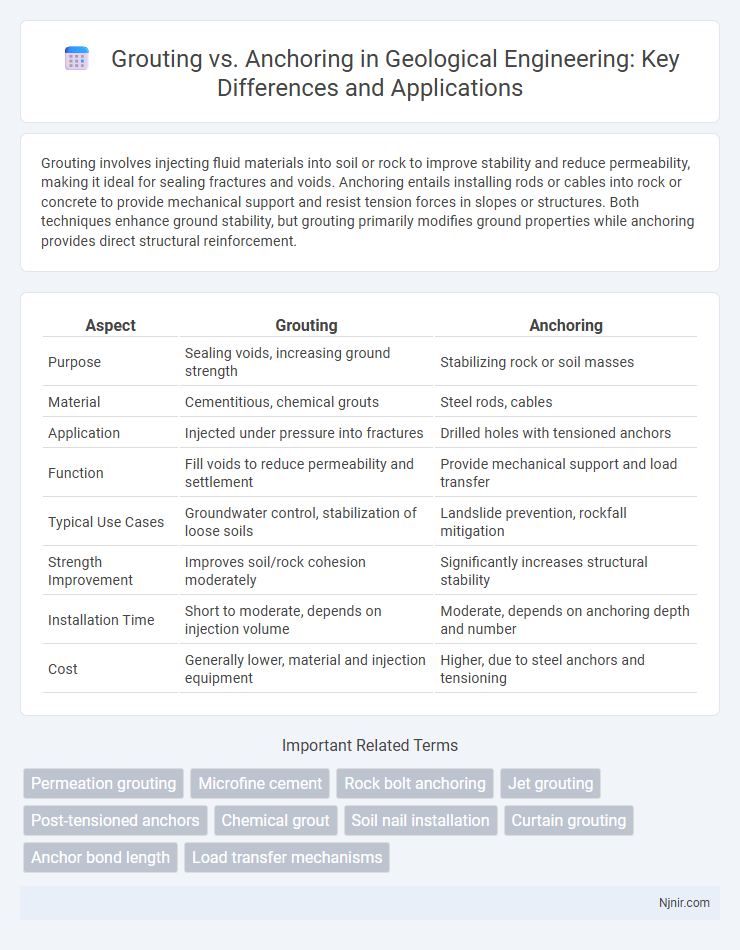

| Aspect | Grouting | Anchoring |

|---|---|---|

| Purpose | Sealing voids, increasing ground strength | Stabilizing rock or soil masses |

| Material | Cementitious, chemical grouts | Steel rods, cables |

| Application | Injected under pressure into fractures | Drilled holes with tensioned anchors |

| Function | Fill voids to reduce permeability and settlement | Provide mechanical support and load transfer |

| Typical Use Cases | Groundwater control, stabilization of loose soils | Landslide prevention, rockfall mitigation |

| Strength Improvement | Improves soil/rock cohesion moderately | Significantly increases structural stability |

| Installation Time | Short to moderate, depends on injection volume | Moderate, depends on anchoring depth and number |

| Cost | Generally lower, material and injection equipment | Higher, due to steel anchors and tensioning |

Introduction to Grouting and Anchoring in Geological Engineering

Grouting involves injecting fluid materials into soil or rock to improve strength and reduce permeability, essential for stabilizing foundations and controlling groundwater in geological engineering. Anchoring secures structural elements to rock or concrete by inserting rods or cables bonded with grout, providing critical support for slopes, tunnels, and retaining walls. Both techniques enhance stability and load-bearing capacity, with grouting primarily improving ground conditions and anchoring ensuring structural fixation.

Definition and Principles of Grouting

Grouting involves the injection of fluid materials like cement, epoxy, or chemical agents into voids or cracks to enhance structural integrity and prevent water ingress. It operates on the principle of filling gaps and binding surfaces to restore strength and reduce permeability in construction or soil stabilization. Anchoring, by contrast, secures structural elements using mechanical fasteners or embedded devices to transfer loads and provide stability rather than sealing or filling voids.

Definition and Principles of Anchoring

Grouting involves filling voids or spaces in masonry or concrete with a fluid material to enhance structural integrity, while anchoring refers to securing structural elements using mechanical or chemical methods. The principle of anchoring relies on transferring loads from the structure to the foundation or base material through embedded devices such as bolts or rods, ensuring stability and resistance to forces. Effective anchoring requires understanding material compatibility, load distribution, and proper installation techniques to achieve optimal performance.

Types of Grouting Techniques

Chemical grouting, permeation grouting, compaction grouting, and jet grouting represent the primary types of grouting techniques used to improve soil stability and strength. Chemical grouting involves injecting chemical solutions into soil pores to create a solid matrix, ideal for sealing and waterproofing. Permeation grouting fills voids without disturbing soil structure, while compaction grouting uses thick grout to densify loose soils, and jet grouting mixes grout and soil through high-pressure jets for deep soil stabilization.

Types of Anchoring Systems

Types of anchoring systems include mechanical anchors, chemical anchors, and grout anchors, each designed for specific load requirements and installation conditions. Mechanical anchors rely on expansion within drilled holes, chemical anchors use adhesive resins for bonding, and grout anchors incorporate cementitious grout to secure the anchor in place. Selection depends on substrate material, load capacity, and environmental factors to ensure optimal performance and durability.

Applications of Grouting in Construction Projects

Grouting is extensively applied in construction projects to fill voids, seal joints, and strengthen foundations by injecting cementitious or chemical mixtures into cracks and gaps. It provides waterproofing for tunnels, improves load transfer in prestressed concrete, and stabilizes soil in foundation repair or ground improvement works. Unlike anchoring, which secures structures through mechanical fasteners, grouting enhances material bonding and structural integrity in both new construction and rehabilitation scenarios.

Applications of Anchoring in Geological Engineering

Anchoring in geological engineering is primarily applied to stabilize slopes, secure retaining walls, and support tunnels by transferring loads to deeper, more stable soil or rock layers. This technique is essential in mitigating landslide risks, reinforcing foundations in weak ground, and providing structural support for excavation sites. Anchors enhance the overall safety and durability of geological structures by maintaining stability in varying soil conditions.

Comparative Analysis: Grouting vs. Anchoring

Grouting provides a high-strength, uniform bond ideal for load transfer in structural applications, while anchoring offers localized fixed points designed to secure fixtures or equipment. Grouting excels in filling voids and ensuring even distribution of stress across large surfaces, whereas anchoring is preferred for direct attachment with immediate load-bearing capacity. The choice between grouting and anchoring depends on project requirements such as load conditions, surface area, and long-term durability needs.

Factors Influencing the Selection Between Grouting and Anchoring

The selection between grouting and anchoring depends on factors such as load requirements, substrate condition, and environmental exposure. Grouting is preferred for filling voids and ensuring uniform load transfer in cracked or irregular concrete, while anchoring is suitable for direct attachment to solid substrates with minimal voids. Consideration of installation speed, material compatibility, and long-term durability also influences the choice between these two methods.

Innovations and Future Trends in Grouting and Anchoring

Innovations in grouting and anchoring emphasize eco-friendly materials such as geopolymer and bio-based grouts that reduce environmental impact while enhancing durability. Advances in injection technology, including microfine cement and dual-component chemical anchors, improve precision and bond strength in complex geological conditions. Future trends focus on automation and monitoring systems using IoT sensors to optimize grouting quality and anchoring performance in real-time for infrastructure resilience.

Permeation grouting

Permeation grouting enhances soil strength and impermeability by injecting low-viscosity grout to fill voids and pores, unlike anchoring which secures structures by mechanical fixation.

Microfine cement

Microfine cement enhances grouting by providing superior penetration and bond strength compared to traditional anchoring methods.

Rock bolt anchoring

Rock bolt anchoring uses grout to secure bolts in rock fractures, providing enhanced stability and load transfer compared to mechanical anchoring methods.

Jet grouting

Jet grouting uses high-pressure fluid jets to create soil-cement columns for ground stabilization, offering greater adaptability and strength compared to traditional grouting and anchoring methods.

Post-tensioned anchors

Post-tensioned anchors rely on grouting to enhance load transfer and corrosion protection, whereas anchoring systems may omit grouting but provide less long-term durability and stress distribution.

Chemical grout

Chemical grout offers superior bonding strength and flexibility compared to traditional mechanical anchoring methods, making it ideal for sealing cracks and stabilizing structures in complex or porous substrates.

Soil nail installation

Grouting enhances soil nail installation by improving soil bonding and load transfer, whereas anchoring provides immediate mechanical support by embedding nails into stabilized soil layers.

Curtain grouting

Curtain grouting enhances soil impermeability and stability by creating a continuous subsurface barrier, differing from anchoring, which primarily secures structures by transferring loads to deeper, stable strata.

Anchor bond length

Anchor bond length in grouting ensures maximum adhesion within the substrate, providing superior load transfer compared to traditional mechanical anchoring methods.

Load transfer mechanisms

Grouting transfers load through bond strength between grout and surrounding material, while anchoring relies on mechanical interlock and friction between the anchor and substrate for load transfer.

grouting vs anchoring Infographic

njnir.com

njnir.com