Dynamic compaction uses heavy weights dropped from heights to increase soil density, making it effective for deep soil layers with granular and cohesive materials. Vibrocompaction involves using vibratory probes to rearrange soil particles, primarily improving loose granular soils by reducing voids and increasing stability. Both methods enhance ground strength but are selected based on soil type, depth, and project requirements.

Table of Comparison

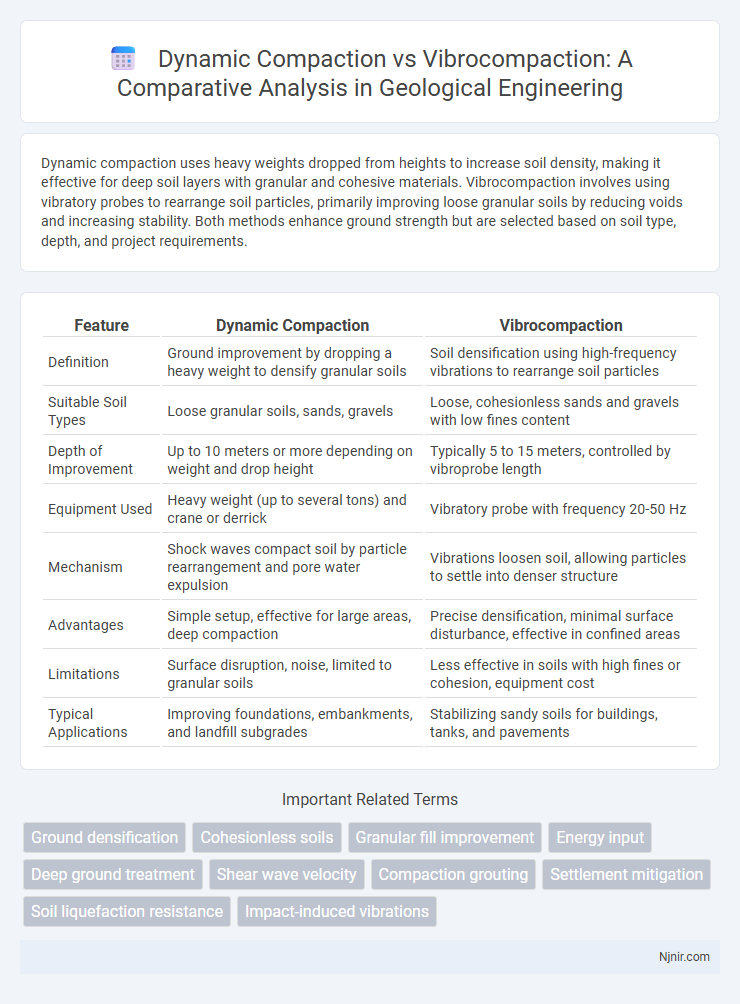

| Feature | Dynamic Compaction | Vibrocompaction |

|---|---|---|

| Definition | Ground improvement by dropping a heavy weight to densify granular soils | Soil densification using high-frequency vibrations to rearrange soil particles |

| Suitable Soil Types | Loose granular soils, sands, gravels | Loose, cohesionless sands and gravels with low fines content |

| Depth of Improvement | Up to 10 meters or more depending on weight and drop height | Typically 5 to 15 meters, controlled by vibroprobe length |

| Equipment Used | Heavy weight (up to several tons) and crane or derrick | Vibratory probe with frequency 20-50 Hz |

| Mechanism | Shock waves compact soil by particle rearrangement and pore water expulsion | Vibrations loosen soil, allowing particles to settle into denser structure |

| Advantages | Simple setup, effective for large areas, deep compaction | Precise densification, minimal surface disturbance, effective in confined areas |

| Limitations | Surface disruption, noise, limited to granular soils | Less effective in soils with high fines or cohesion, equipment cost |

| Typical Applications | Improving foundations, embankments, and landfill subgrades | Stabilizing sandy soils for buildings, tanks, and pavements |

Introduction to Ground Improvement Techniques

Dynamic compaction improves soil density by repeatedly dropping heavy weights on the ground, effectively increasing bearing capacity and reducing settlement in granular and mixed soils. Vibrocompaction uses high-frequency vibrations to rearrange soil particles, ideal for loose, cohesionless soils like sands and gravels, enhancing soil stability and preventing liquefaction. Both techniques are essential ground improvement methods tailored for different soil conditions to optimize foundation performance and reduce construction risks.

Overview of Dynamic Compaction

Dynamic compaction involves repeatedly dropping a heavy weight from a significant height to densify loose granular soils and improve bearing capacity, typically used in granular and mixed soils at depths up to 20 meters. This method creates shock waves that rearrange soil particles, reduces voids, and increases soil density without the need for vibratory equipment. Often favored for its rapid application and ability to treat a variety of soil types, dynamic compaction addresses settlement issues and enhances foundation stability effectively.

Overview of Vibrocompaction

Vibrocompaction is a ground improvement technique that increases soil density by using a vibrating probe to rearrange soil particles, typically effective in granular soils like sands and gravels. Unlike dynamic compaction, which employs heavy weights dropped from heights to compact soil, vibrocompaction applies vibration deep into the ground to eliminate voids and improve bearing capacity. This method enhances soil stability, reduces settlement, and is particularly useful for supporting foundations and infrastructure on loose, cohesionless soils.

Soil Types Suitable for Dynamic Compaction

Dynamic compaction is most effective in granular soils such as loose sands, silty sands, and gravelly sands, where the impact energy densifies the soil by rearranging particles and reducing void ratios. Cohesive soils with high plasticity, like clays, typically respond less to dynamic compaction due to their low permeability and plastic behavior. Vibrocompaction, in contrast, is better suited for uniformly graded, cohesionless soils with low fines content, as it relies on vibratory energy to realign particles and increase density.

Soil Types Suitable for Vibrocompaction

Vibrocompaction is particularly effective for loose, granular soils such as clean sands, silty sands, and other cohesionless materials with minimal fines content, typically less than 15%. This method improves soil density by rearranging soil particles through vibratory energy, making it unsuitable for clayey or highly cohesive soils that resist particle movement. Dynamic compaction, by contrast, can be applied to a broader range of soil types, including cohesionless and some cohesive soils, but vibrocompaction is specifically optimized for relatively dry, well-graded granular soils.

Equipment and Methodology Comparison

Dynamic compaction employs heavy weights, typically ranging from 10 to 40 tons, dropped from heights of 10 to 30 meters to densify loose granular soils, utilizing impact energy to increase soil bearing capacity. Vibrocompaction uses a vibrating probe that penetrates the soil, emitting frequencies between 20 to 40 kHz to rearrange soil particles, particularly effective in granular, cohesionless soils with low fines content. Equipment for dynamic compaction involves cranes or drop weight systems, while vibrocompaction requires specialized vibratory probes coupled with air or water jets to facilitate deeper soil penetration and compaction.

Performance and Depth of Improvement

Dynamic compaction achieves ground improvement by dropping heavy weights to densify soils, typically effective at depths up to 10 meters, offering rapid compaction for granular and some cohesive soils. Vibrocompaction employs high-frequency vibrations to rearrange soil particles, enabling deeper treatment--often exceeding 15 meters--making it ideal for loose, saturated granular deposits. Performance-wise, dynamic compaction excels in surface densification with faster setup times, while vibrocompaction provides more uniform densification at greater depths but requires specialized equipment and longer process durations.

Environmental and Safety Considerations

Dynamic compaction involves dropping heavy weights repeatedly on soil, which generates significant noise, vibrations, and ground disturbance, potentially impacting nearby structures and ecosystems. Vibrocompaction uses vibratory probes to densify granular soils with less noise and reduced ground vibrations, lowering risks to adjacent buildings and minimizing environmental disruption. Both methods require careful site assessment to manage dust emissions, ground stability, and ensure worker safety through appropriate protective measures and monitoring protocols.

Cost Analysis: Dynamic Compaction vs Vibrocompaction

Dynamic compaction generally incurs lower initial costs compared to vibrocompaction due to simpler equipment and reduced operational complexity. Vibrocompaction, while more expensive upfront, offers greater precision and suitability for sandy soils, often leading to cost savings in long-term settlement control. Cost analysis should account for soil conditions, project scale, and performance requirements to determine the most economically viable method.

Case Studies and Practical Applications

Dynamic compaction employs heavy weights dropped from heights to densify granular soils, proving effective in large-scale projects like airport runways in Japan and highway embankments in the United States. Vibrocompaction uses vibratory probes to rearrange soil particles, widely implemented in sandy soils beneath high-rise buildings in the Middle East and coastal reclamation sites in the Netherlands. Case studies highlight dynamic compaction's superiority in deep fills and vibrocompaction's efficiency in uniform granular soils, influencing technique selection for foundation improvement and liquefaction mitigation.

Ground densification

Dynamic compaction densifies loose granular soils by dropping heavy weights to create deep soil compaction, while vibrocompaction uses vibratory probes to rearrange soil particles for improved ground density in sandy and granular soils.

Cohesionless soils

Dynamic compaction improves density in cohesionless soils by dropping heavy weights to increase particle interlock, while vibrocompaction uses high-frequency vibrations to rearrange granular particles, enhancing soil density and stability.

Granular fill improvement

Dynamic compaction and vibrocompaction enhance granular fill stability by increasing soil density, with dynamic compaction applying heavy repeated impacts for deeper compaction and vibrocompaction using vibratory probes to rearrange soil particles at shallower depths.

Energy input

Dynamic compaction delivers high-energy impact blows to densify deep loose soils, whereas vibrocompaction uses low-frequency vibrations to rearrange granular soil particles with lower energy input.

Deep ground treatment

Dynamic compaction involves dropping heavy weights to densify deep soil layers, while vibrocompaction uses vibration to rearrange granular particles and improve soil density in deep ground treatment applications.

Shear wave velocity

Dynamic compaction increases shear wave velocity primarily by densifying soil through heavy tamping, while vibrocompaction enhances shear wave velocity by rearranging granular soil particles using vibratory energy.

Compaction grouting

Compaction grouting differs from dynamic and vibrocompaction by injecting stiff grout to displace and densify loose soils, providing targeted ground improvement ideal for underpinning and soil stabilization.

Settlement mitigation

Dynamic compaction reduces settlement by densifying loose granular soils through heavy weight drops, while vibrocompaction mitigates settlement by using vibratory probes to rearrange soil particles and increase density, particularly effective in sandy and granular soils.

Soil liquefaction resistance

Dynamic compaction improves soil liquefaction resistance by densifying loose granular soils through heavy tamping, while vibrocompaction enhances resistance by using vibratory probes to rearrange soil particles and increase density in cohesionless soils.

Impact-induced vibrations

Dynamic compaction generates deep, impact-induced vibrations by dropping heavy weights to densify soil, while vibrocompaction uses high-frequency vibrations from a vibrating probe to densify granular soils with less impact-induced vibration.

Dynamic compaction vs Vibrocompaction Infographic

njnir.com

njnir.com